Get the free Material Safety Data Sheet - SKYLT

Get, Create, Make and Sign material safety data sheet

How to edit material safety data sheet online

Uncompromising security for your PDF editing and eSignature needs

How to fill out material safety data sheet

How to fill out material safety data sheet

Who needs material safety data sheet?

Understanding the Material Safety Data Sheet Form: A Comprehensive Guide

Understanding Material Safety Data Sheets (MSDS)

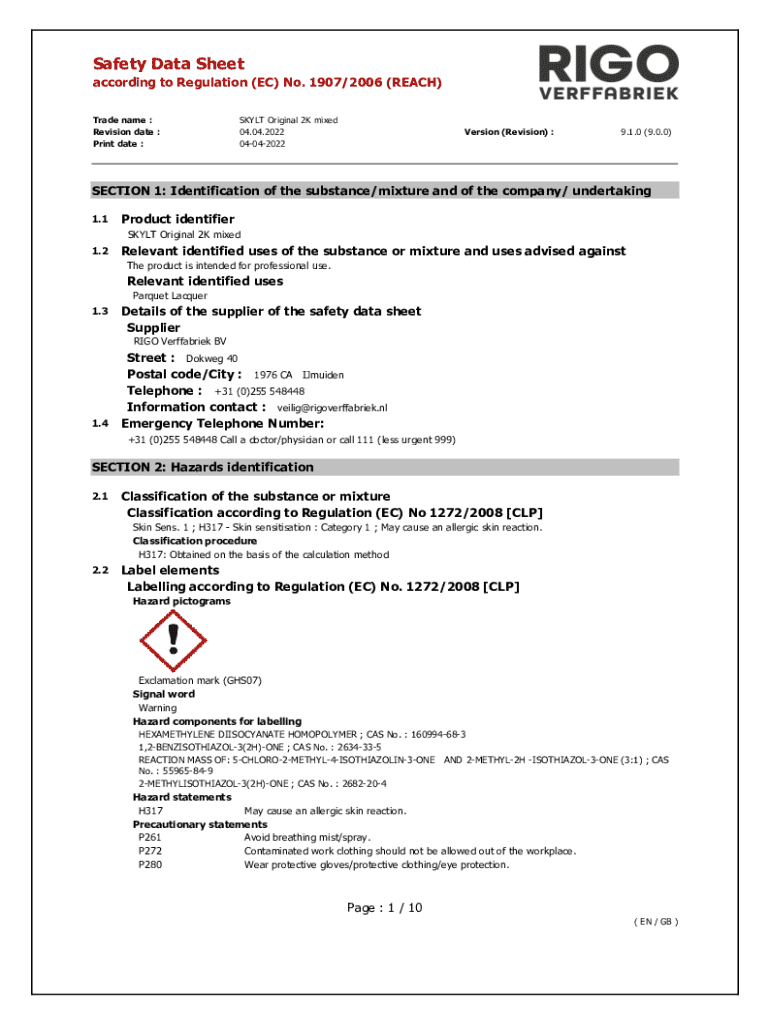

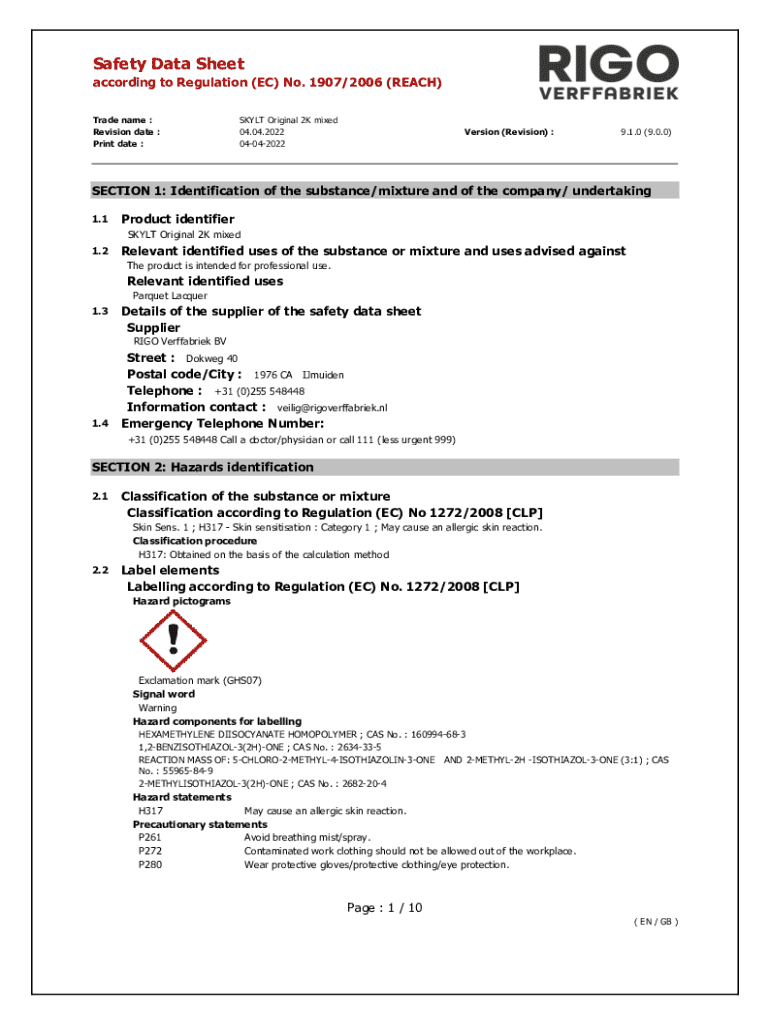

A Material Safety Data Sheet (MSDS) is a vital document that provides comprehensive information about a specific chemical substance or product. It serves as a fundamental tool for ensuring workplace safety by detailing hazards, handling instructions, and emergency procedures. The importance of MSDS in safety management cannot be overstated; they empower employers and employees to recognize and mitigate risks associated with hazardous materials. In workplaces where chemicals are prevalent, an MSDS is essential for educating staff on safe practices and compliance with regulations.

The primary purpose of an MSDS is to inform employees about potential hazards related to chemicals they might encounter. This includes physical hazards like flammability and health hazards such as toxicity. An effective MSDS aids in planning precautionary measures to prevent workplace accidents, making it an indispensable component in operational protocols.

Historical context and evolution of MSDS

Historically, MSDS documents date back to the early 20th century when occupational health and safety started gaining prominence. Originally, they were unstandardized and varied in format across regions and manufacturers. The lack of consistent guidelines led to confusion and increased risks, which was particularly concerning for industries heavily reliant on chemicals. The transition to standardized MSDS began in the 1980s, driven by the need for greater global safety practices.

In recent years, the advent of the Globally Harmonized System (GHS) has revolutionized the approach to safety data sheets. The GHS introduced a unified classification system and standardized labeling requirements to promote consistent hazard communication internationally. This evolution ensures that an MSDS is more user-friendly and provides clear guidance, aiding not only manufacturers but also users in understanding the hazards associated with chemicals.

Components of an MSDS

An MSDS typically comprises several key sections that provide a structured layout for conveying critical information. The major components include:

Understanding chemical classifications in MSDS is also essential. The GHS classifications utilize hazard pictograms to visually communicate risks. This visual tool helps workers quickly identify potential dangers associated with various chemical classes, ensuring they take appropriate actions to mitigate those hazards.

How to fill out a Material Safety Data Sheet

Filling out a Material Safety Data Sheet requires attention to detail and knowledge about the materials involved. Here’s a step-by-step guide to help you navigate this process effectively:

Common mistakes to avoid during this process include incomplete sections, misrepresentation of data, and neglecting to keep MSDS information current. It is critical to maintain accuracy, as even minor errors can lead to significant safety risks and compliance issues.

Utilizing interactive tools for MSDS management

Technology's role in MSDS creation and management cannot be underestimated. Digital forms offer advantages over traditional paper-based systems, making the process more efficient and accessible. A platform like pdfFiller provides intuitive editing capabilities that simplify the management of safety data sheets. Key benefits include:

Accessing and updating your MSDS from anywhere streamlines the safety management process. With the ability to track versions and changes, organizations can ensure compliance with evolving safety regulations more effectively.

Implementing MSDS in workplace safety protocols

To maximize the effectiveness of MSDS, training employees on their proper use is crucial. Employees must understand how to locate information within the MSDS and interpret its various sections. Recommended training methods include hands-on workshops, online courses, and providing access to MSDS databases for comprehensive learning.

Integrating MSDS into safety programs increases overall workplace safety. This involves revisiting existing health and safety plans to incorporate the latest safety data sheets. Regular reviews and updates must be scheduled to ensure compliance and accuracy, aligning with changes in the workplace and regulations.

Compliance and regulatory considerations

Understanding the legal requirements for MSDS is essential for regulatory compliance. The Occupational Safety and Health Administration (OSHA) mandates that manufacturers provide an MSDS for hazardous chemicals as part of the Hazard Communication Standard (HCS). Employers are required to make these sheets accessible to their employees to promote workplace safety.

Regular updates and meticulous record-keeping are vital in maintaining compliance. OSHA guidelines recommend reviewing and revising MSDS whenever chemicals undergo changes in formulation or new scientific data becomes available. Establishing an ideal schedule for reviewing and updating safety data sheets can prevent potential legal repercussions and ensure workplace safety remains a priority.

Conclusion: Embracing comprehensive document management

Accurate MSDS have a critical role in promoting safety within workplaces. They provide essential information that ensures employees can work with hazardous materials safely and effectively. Embracing comprehensive document management through tools like pdfFiller can streamline MSDS creation and maintenance. By empowering users to edit, sig, collaborate, and manage documents seamlessly from a single cloud-based platform, pdfFiller simplifies the complexities traditionally associated with MSDS management.

In conclusion, maintaining accessible and editable safety documents is not just about compliance; it’s about creating a culture of safety where every employee feels empowered to work safely.

For pdfFiller’s FAQs

Below is a list of the most common customer questions. If you can’t find an answer to your question, please don’t hesitate to reach out to us.

How can I get material safety data sheet?

How do I fill out the material safety data sheet form on my smartphone?

How do I fill out material safety data sheet on an Android device?

What is material safety data sheet?

Who is required to file material safety data sheet?

How to fill out material safety data sheet?

What is the purpose of material safety data sheet?

What information must be reported on material safety data sheet?

pdfFiller is an end-to-end solution for managing, creating, and editing documents and forms in the cloud. Save time and hassle by preparing your tax forms online.