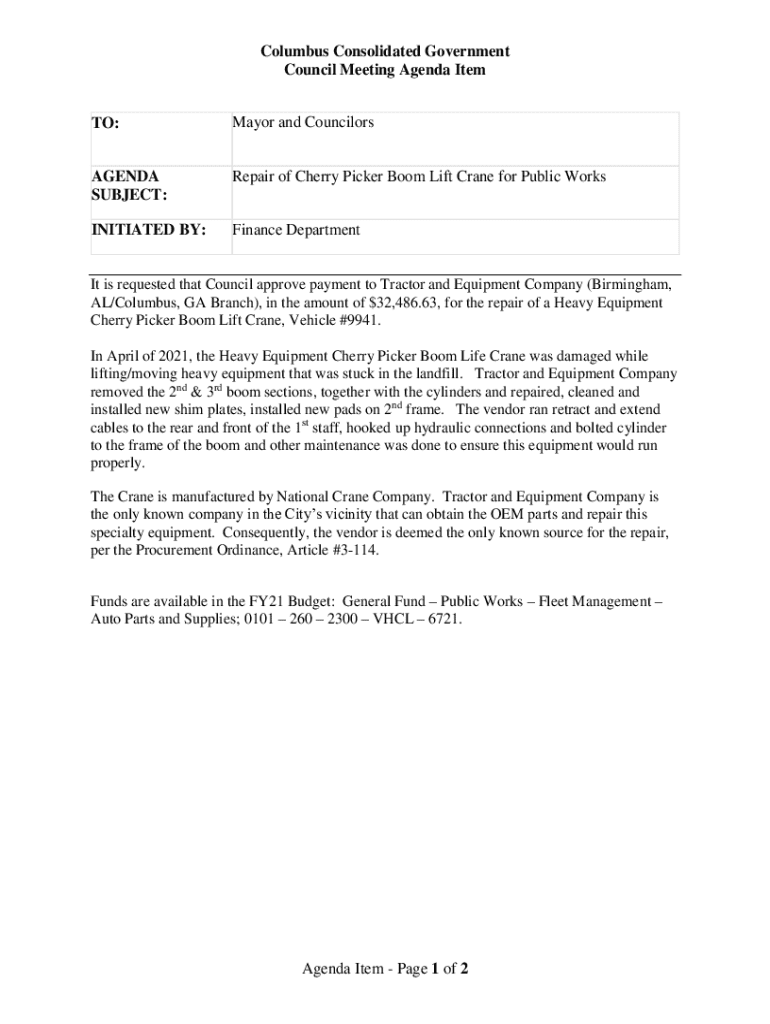

Get the free Repair of Cherry Picker Boom Lift Crane for Public Works

Get, Create, Make and Sign repair of cherry picker

How to edit repair of cherry picker online

Uncompromising security for your PDF editing and eSignature needs

How to fill out repair of cherry picker

How to fill out repair of cherry picker

Who needs repair of cherry picker?

Repair of Cherry Picker Form: A Comprehensive Guide

Understanding cherry picker repairs

Cherry pickers, also known as aerial work platforms, are essential in various industries for reaching elevated workspaces. They are used in construction, maintenance, and entertainment sectors for tasks such as installing lighting, performing repairs, or even picking fruit. Their ability to lift individuals and equipment to significant heights makes them indispensable.

There are several types of cherry pickers, including boom lifts, scissor lifts, and truck-mounted platforms. Boom lifts provide a greater reach for horizontal and vertical workspace, while scissor lifts offer stability and increased lifting capacity over shorter distances.

Regular maintenance of cherry pickers is crucial. It not only ensures operational efficiency but also significantly mitigates risks associated with equipment failure. A well-maintained cherry picker reduces the likelihood of accidents and enhances the safety of operators and other personnel working nearby.

Identifying common issues in cherry pickers

When using cherry pickers, it's critical to recognize common issues that may arise. Mechanical failures are among the most common problems, including hydraulic leaks, boom malfunction, and wear on moving parts. These failures can lead to reduced lift capability and pose a significant safety risk if not addressed promptly.

Electrical malfunctions are another common concern with cherry pickers. Issues can range from battery failures to wiring problems that affect operation. Diagnosing these electrical faults requires systematic checks, such as verifying battery voltage and ensuring wiring integrity.

Furthermore, inspecting safety equipment is paramount in preventing accidents. Essential safety components like harnesses, emergency brakes, and alarms must be regularly verified to meet safety standards and ensure the wellbeing of operators.

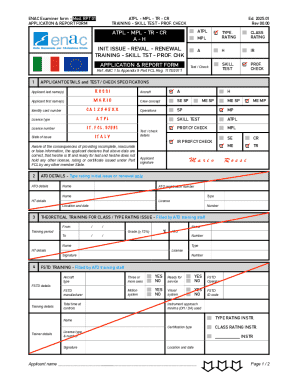

Preparing for a cherry picker repair

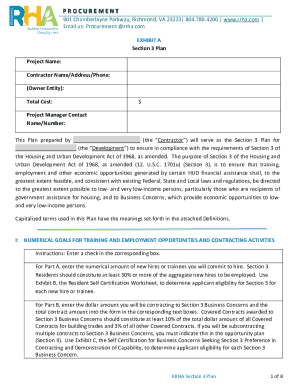

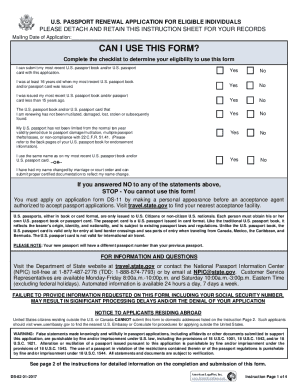

Before diving into repairs, proper preparation is key. Gathering documentation is essential; this includes maintenance logs that track what has been serviced and part replacement records. Keeping a precise record of previous repairs can inform technicians of recurring issues and potential underlying defects that need addressing.

In addition to documentation, having the right tools and equipment is vital. This includes basic hand tools, specialized hydraulic tools, and diagnostic equipment. Furthermore, always ensure that appropriate safety gear—such as gloves, helmets, and safety goggles—are ready before starting any repair work to maintain a safe working environment.

Step-by-step guide to repairing common issues

Repairing hydraulic system failures involves multiple steps. Start by diagnosing where the leak is occurring. Once identified, isolate the hydraulic system and depressurize it. Next, small leaks might require simply tightening fittings, whereas significant leaks may necessitate replacing hoses or seals.

For electrical problems, begin by troubleshooting wiring issues. Check fuses and circuit breakers, followed by ensuring connections are secure. If necessary, replace any faulty electrical components like switches or relays. This benchmarking ensures that all components are functioning effectively.

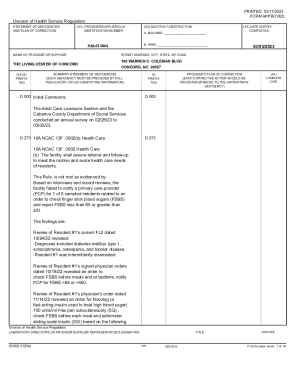

Additionally, safety feature inspections should follow a systematic checklist. Verify the operational status of safety harnesses, ensure emergency brakes engage properly, and check that alarms and lights function as required. Documenting these checks will aid in maintaining a high safety standard.

Utilizing the cherry picker repair form

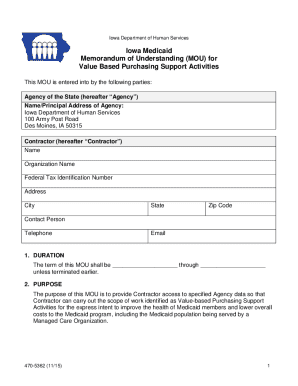

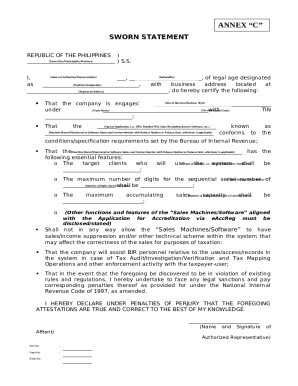

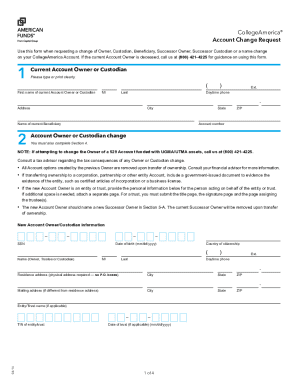

The Cherry Picker Repair Form plays an essential role in documenting repairs. Its main purpose is to keep accurate records that can enhance maintenance tracking and facilitate better decision-making regarding repairs and replacements. Regularly using the form ensures that all necessary information is logged and retained for future reference.

Important information to include on the repair form encompasses a detailed issue description, parts replaced, and technician notes regarding the repairs performed. This information creates an invaluable history that helps in identifying patterns and anticipating future maintenance needs.

For effective use of the form, adopting best practices is key. Use clear, concise language when filling out the form. Ensure all fields are completed consistently; when utilizing a digital format, employ pdfFiller’s tools to access, edit, and maintain the form easily. This helps streamline communication among technicians and supervisors.

Interactive tools for cherry picker repair management

Digital solutions are transforming how maintenance tracking is approached. Platforms like pdfFiller allow users to create, edit, and manage repair forms from anywhere. Its features include easy-to-use templates and real-time collaboration capabilities, streamlining the documentation process.

The benefits of using digital documents over traditional paper forms are numerous. Digital solutions alleviate the risk of lost paperwork and provide easy access to historical data. Furthermore, utilizing integrations for fleet management software can enhance quality defect management, allowing for quicker decision-making and more efficient maintenance processes.

Accessing additional templates and resources

Users looking for a Cherry Picker Repair Form Template can find free resources available online. These templates can be easily customized to meet specific maintenance needs and ensure compliance with industry standards. Utilizing such templates can eliminate the need to start from scratch, saving significant time and effort.

Beyond cherry picker repair forms, there are numerous related templates for equipment management that can aid in more comprehensive documentation. These might include forms for quality planning, work orders, and timesheets. With a robust suite of templates, users can enhance their operations significantly.

Best practices for ongoing cherry picker maintenance

Establishing regular inspection protocols is vital for cherry picker maintenance. Inspections should occur at least once a month, with more frequent evaluations during peak usage periods. Regular checks not only prevent unexpected failures but also keep track of wear and tear that could lead to more significant problems if unaddressed.

Additionally, keeping detailed records is crucial. Every repair and inspection should be logged meticulously in a dedicated maintenance log. This habit aids technicians in recognizing trends, understanding equipment lifecycles, and helps in forecasting future maintenance timelines and costs.

Finally, operator training ensures that personnel are equipped to use cherry pickers safely and effectively. Regular training updates, emphasizing safety protocols and operational procedures, promote a culture of safety and efficiency within a team.

For pdfFiller’s FAQs

Below is a list of the most common customer questions. If you can’t find an answer to your question, please don’t hesitate to reach out to us.

How can I edit repair of cherry picker on a smartphone?

How do I fill out repair of cherry picker using my mobile device?

How do I fill out repair of cherry picker on an Android device?

What is repair of cherry picker?

Who is required to file repair of cherry picker?

How to fill out repair of cherry picker?

What is the purpose of repair of cherry picker?

What information must be reported on repair of cherry picker?

pdfFiller is an end-to-end solution for managing, creating, and editing documents and forms in the cloud. Save time and hassle by preparing your tax forms online.