Get the free Repair of Bulldozer (Vehic

Get, Create, Make and Sign repair of bulldozer vehic

Editing repair of bulldozer vehic online

Uncompromising security for your PDF editing and eSignature needs

How to fill out repair of bulldozer vehic

How to fill out repair of bulldozer vehic

Who needs repair of bulldozer vehic?

Repair of bulldozer vehicle form: A comprehensive how-to guide

Understanding the repair of bulldozer vehicle form

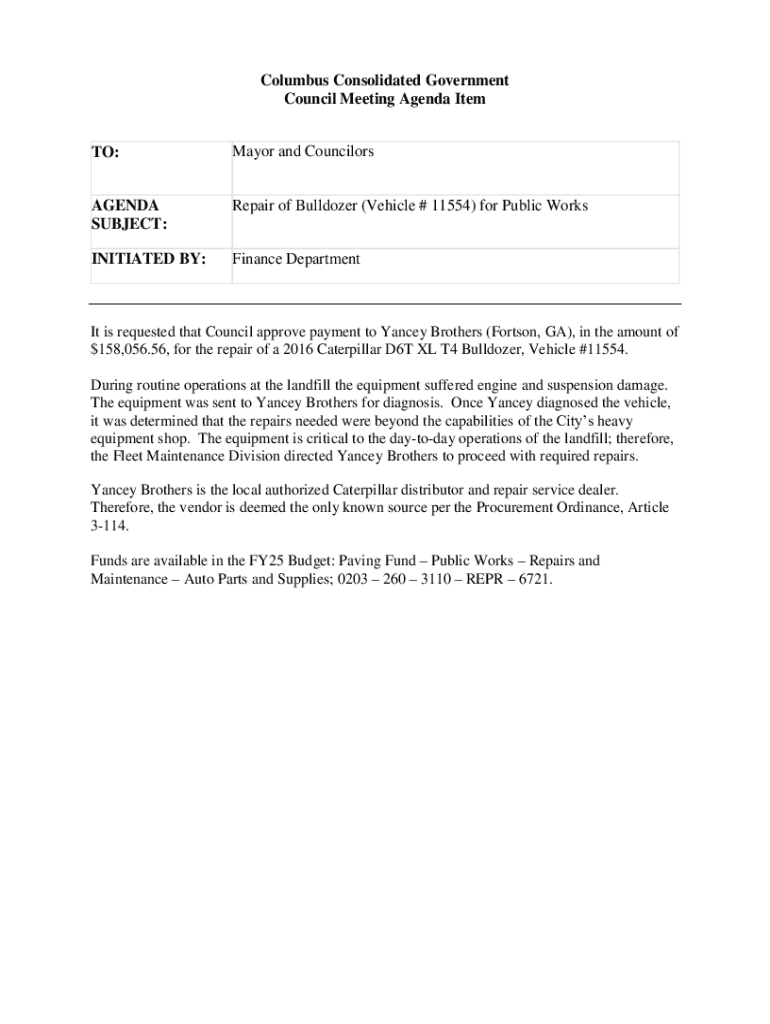

The repair of bulldozer vehicle form is a crucial document used in the maintenance management of bulldozers. Its primary purpose is to systematically record any issues related to the equipment's functionality and safety. Ensuring this form is filled out accurately supports compliance with OSHA requirements and documentation standards that safeguard operators and the equipment itself.

Using the repair form effectively can enhance equipment lifespan by documenting repairs carried out and outlining recommended future actions. It's a vital tool for teams committed to maintaining equipment integrity, ensuring compliance, and reducing the probability of machinery failure in high-pressure construction environments.

Common reasons for filing a repair of bulldozer vehicle form

There are numerous common issues that necessitate the filling of a repair of bulldozer vehicle form. Mechanical failures can range from engine troubles to hydraulic system malfunctions. Routine maintenance updates and safety inspections are also pivotal reasons for compiling this form, ensuring compliance with safety regulations and manufacturer requirements.

Delaying the reporting of these issues can have severe consequences. For instance, operational shutdowns due to equipment failures can lead to costly downtime and project delays. Furthermore, neglecting to adhere to thorough documentation can create legal liabilities and operational risks, including violations of state protocols and safety inspections.

Step-by-step instructions for filling out the repair of bulldozer vehicle form

Before completing the repair of bulldozer vehicle form, some preparation is necessary. Gather critical information such as a copy of maintenance records, equipment serial numbers, and any relevant performance reports. Identify the specific parts and systems requiring repair, ensuring you have documented all symptoms and observations that led to the conclusion of a malfunction.

When filling out the form, pay careful attention to each section. In Section 1, provide the necessary equipment information including the make, model, and year of manufacture. Section 2 should accurately describe the issues encountered, detailing symptoms and any unusual behaviors noted. In Section 3, report on maintenance history to showcase issues' frequency and previous resolutions. Lastly, Section 4 can consist of recommendations for repair services or immediate actions necessary to rectify the problems.

Digital tools for managing the repair of bulldozer vehicle form

Utilizing digital tools, such as pdfFiller, streamlines the management of the repair of bulldozer vehicle form. With comprehensive features that support interactive form filling, users can customize their forms and easily share them with team members. This enhances accessibility and ensures that essential documents are always at hand regardless of location.

One standout feature of pdfFiller is its capability for initiating e-signatures directly through the platform. This process simplifies approval workflows and ensures compliance across various equipment management processes. Furthermore, inviting team members to view or edit forms and tracking all changes improves document accuracy and accountability within a team setting.

Compliance and documentation standards for bulldozer repairs

Compliance with local and federal regulations is paramount in the operation of heavy machinery like bulldozers. Familiarizing yourself with OSHA requirements and other documentation standards is essential for maintaining both safety and legality in operations. Failure to comply can result in audits, penalties, or even cessation of operations in severe cases.

Documentation best practices include ensuring that all repairs are logged with clarity and precision. This practice supports transparency throughout the organization and fosters accountability among team members. Utilizing standards forms encourages uniformity in reporting, simplifying inspections, and aiding in regulatory compliance.

Case studies: Effective use of the repair of bulldozer vehicle form

Case study narratives demonstrate the effectiveness of timely documentation. For instance, one construction company faced repeated hydraulic failures, threatening project timelines. By routinely filling out the repair of bulldozer vehicle form, they identified a faulty component early, allowing prompt replacement and preventing a more significant breakdown. Constant monitoring and updating their records facilitated timely repairs, significantly minimizing potential downtime.

Another business leveraged the repair of bulldozer vehicle form to ensure adherence to compliance. Routine inspections outlined in their documentation provided verifiable proof of diligence, successfully passing several OSHA audits without violations. The clear, well-maintained records not only ensured compliance but also fostered trust and demonstrable safety standards within their operational practices.

Risks of non-compliance in bulldozer repair documentation

Neglecting to file detailed repair documentation poses several risks. Legally, organizations may face liabilities associated with equipment failure due to improper maintenance practices, which could lead to accidents on jobsites. Understanding the systems and processes related to documentation is crucial for compliance and mitigating these risks.

Operational risks can also arise from failing to report issues accurately. Maintenance departments equipped with proper records can address problems swiftly, ensuring that machinery operates efficiently and safely. Non-compliance not only jeopardizes equipment lifespan but can also severely affect workplace safety, increasing the chance of accidents and subsequent regulatory scrutiny.

Frequently asked questions (FAQs) about the repair of bulldozer vehicle form

One common query regarding the repair of bulldozer vehicle forms is what to do if there is missing information. In such cases, it is critical to document any known details and indicate uncertainty in the form clearly. A well-noted explanation is better than providing incomplete information.

Ensuring the form is filled out correctly involves multiple checks. Double-checking entries against maintenance records and prior reports helps to solidify the accuracy of data provided. Always seek clarity in descriptions and maintain open communication with the team inspecting or managing the repairs.

After submitting the form, users can expect follow-up communications regarding the proposed repairs. Depending on company protocols, the form may undergo management review, approval, or immediate action for repairs needed. Regular updates regarding the status of the repairs can also be anticipated.

Conclusion

The importance of accurately and promptly using the repair of bulldozer vehicle form cannot be overstated. As machinery becomes increasingly integral to efficient operations, maintaining compliance, safety, and effective equipment management is just as critical. Users should leverage this form as part of their routine processes to ensure they mitigate risks and contribute to a successful operational environment.

Leveraging technology for ongoing compliance

Integrating repair forms into business operations through cloud-based solutions like pdfFiller represents the future of construction documentation management. With features that enhance accessibility, ease of use, and interactive capabilities, teams can assure compliance while maintaining flexibility in their workflows. This evolution facilitates continual management oversight and safeguards against potential regulatory breaches.

Additional tools available on pdfFiller

In addition to the repair of bulldozer vehicle form, pdfFiller offers an array of documentation solutions tailored for vehicle inspections and repairs. Users can explore various templates to fulfill diverse operational needs, enabling comprehensive monitoring and management. The analytics features available within the platform further assist users in tracking compliance adherence and understanding form metrics, ensuring robust equipment management practices.

For pdfFiller’s FAQs

Below is a list of the most common customer questions. If you can’t find an answer to your question, please don’t hesitate to reach out to us.

How can I get repair of bulldozer vehic?

How do I fill out the repair of bulldozer vehic form on my smartphone?

How do I edit repair of bulldozer vehic on an Android device?

What is repair of bulldozer vehic?

Who is required to file repair of bulldozer vehic?

How to fill out repair of bulldozer vehic?

What is the purpose of repair of bulldozer vehic?

What information must be reported on repair of bulldozer vehic?

pdfFiller is an end-to-end solution for managing, creating, and editing documents and forms in the cloud. Save time and hassle by preparing your tax forms online.