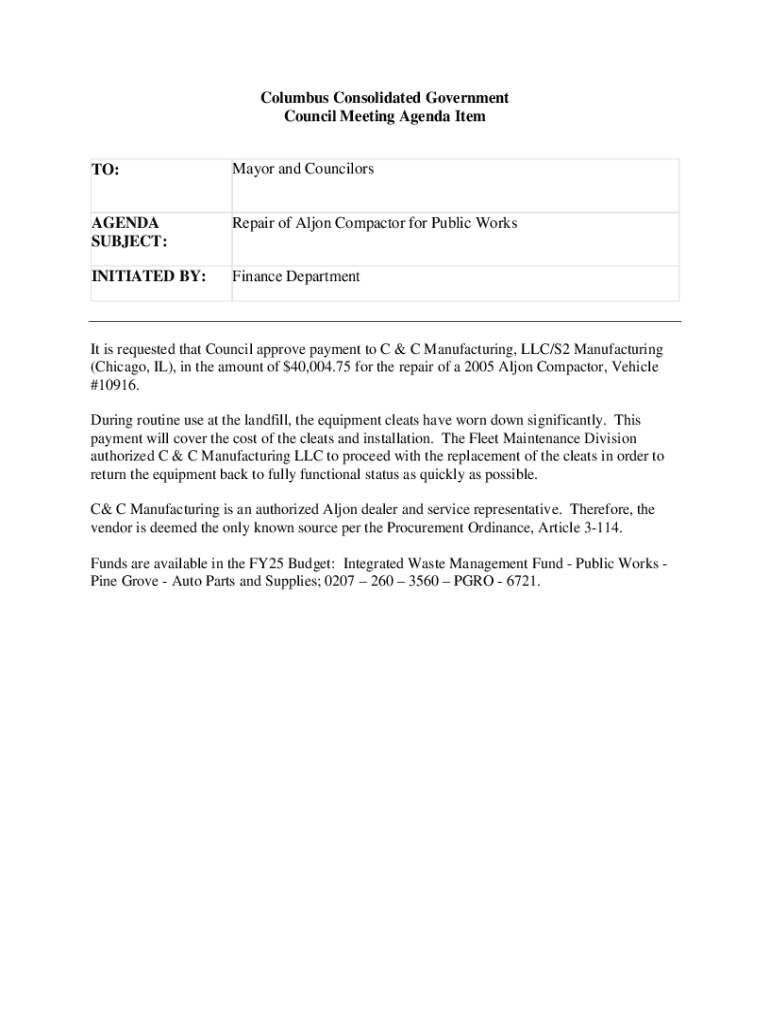

Get the free Repair of Aljon Compactor

Get, Create, Make and Sign repair of aljon compactor

Editing repair of aljon compactor online

Uncompromising security for your PDF editing and eSignature needs

How to fill out repair of aljon compactor

How to fill out repair of aljon compactor

Who needs repair of aljon compactor?

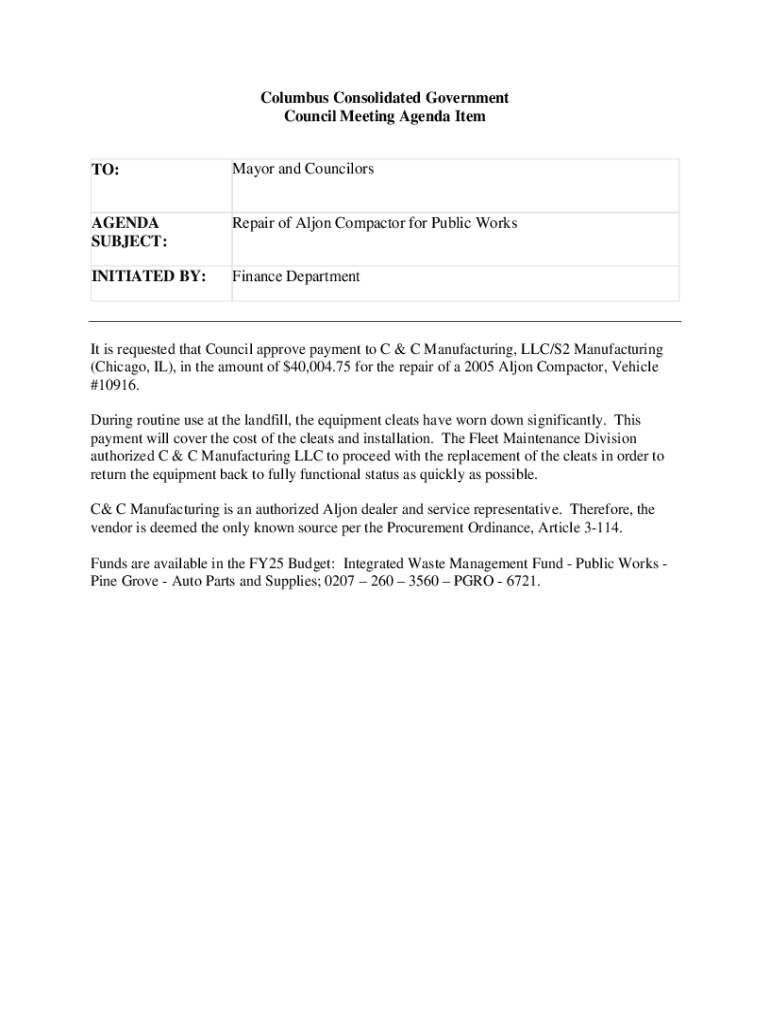

Repair of Aljon Compactor Form: A Comprehensive Guide

Understanding the Aljon compactor

Aljon compactors are renowned for their durability and efficiency in handling waste materials and recycling tasks across various industries. Notable models include the Aljon 580CL, Aljon AC-30, and Aljon 400, each designed to meet different operational needs. The compactors are commonly used in settings such as landfills, demolition sites, and recycling operations, where robust performance is critical.

Maintenance and repair of these machines is imperative; neglecting such duties not only shortens the lifespan of the compactor but also leads to costly downtime and operations disruption. Regular inspections and timely repairs ensure optimal performance and mitigate the risk of unexpected breakdowns.

Preparing for the repair process

Before diving into repairs, it's crucial to gather the necessary tools and materials. Essential tools for repairing Aljon compactors generally include wrenches, screwdrivers, hydraulic fluid, oil, and electrical diagnostic equipment. Additionally, wearing appropriate safety gear such as gloves, goggles, and helmets is non-negotiable to protect yourself during the repair process.

Identifying the need for repair is equally important. Look for signs indicating malfunction, which can include unusual noises, fluid leaks, decreased performance, and error codes displayed on the control panel. Performing a diagnostic check can help pinpoint the precise issue, thus streamlining repair efforts.

Comprehensive guide to the repair of Aljon compactor

The repair process can be broken down into specific sections addressing critical components of the Aljon compactor. Understanding these elements will aid in executing effective repairs.

Engine repair and maintenance

Engine-related issues are among the most common complaints. Symptoms may include stalling, overheating, or lack of power. Common solutions often involve changing the oil and filters, replacing spark plugs, or adjusting ignition timing. For detailed engine repairs, ensure to follow these steps carefully:

Hydraulic system troubleshooting

Hydraulic systems are vital for the effective operation of the compactor. Common hydraulic problems include leaks, slow response times, and abnormal noises. To address these issues, adhere to the following troubleshooting steps:

Electrical system checks

Electrical malfunctions can lead to unresponsive controls or error messages. Verify all wiring connections and inspect fuses for functionality. If replacement is necessary, ensure to utilize quality parts aligned with factory specifications, as this can affect the performance and warranty of the unit.

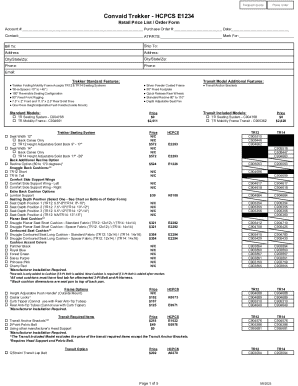

Parts replacement and upgrades

Deciding between repairing a part or replacing it can be challenging. Generally, if a part is showing significant wear or has already been repaired several times, replacement is the prudent choice. Recommended parts for Aljon compactors can be sourced through authorized dealers or reputable aftermarket suppliers. While considering upgrades, evaluate options that enhance performance, maintain compatibility with the existing components, and comply with OEM standards.

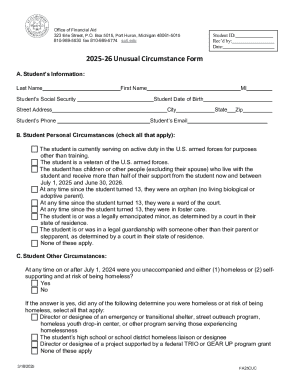

Utilizing pdfFiller for your repair documentation

Creating and keeping track of your Aljon compactor repair forms is essential for organized maintenance records. To access the repair form through pdfFiller, follow these steps:

Editing the form digitally not only streamlines the documentation process but also reduces paperwork clutter. Ensure all information is accurate, as this will aid in tracking repairs and communicating with your team.

Post-repair actions

Once repairs are completed, conducting a final inspection is pivotal. Verify all replaced parts and ensure they are functioning properly. A checklist should guide this verification process, addressing each component's performance. Post-repair performance testing is essential; running the compactor should confirm that it operates effectively without unexpected issues.

To maintain your compactor after repairs, adopt best practices including regular inspections, creating a maintenance schedule, and ensuring all operators are trained in care and usage. The goal is to prolong the life of your equipment while maintaining optimal working conditions.

Data management and collaboration

Sharing repair documentation among team members enhances transparency and efficiency in maintenance practices. Through pdfFiller, users can easily distribute repair records via email or grant access to colleagues for collaborative efforts. Utilizing these capabilities can streamline repair processes and keep everyone informed of the compactor's status.

Tracking repair history offers invaluable insights into equipment performance. Regular logs of repairs and maintenance can highlight recurring issues, enabling proactive measures to mitigate future problems. Utilizing pdfFiller for tracking historical repair data centralizes documentation and fosters efficient data management.

Troubleshooting common repair issues

During repairs, certain problems are frequently encountered, such as trapped debris in the hydraulic lines or loose electrical connections. Addressing these quick fixes can often resolve issues promptly without extensive downtime. Keeping a toolkit stocked with replacement fuses, hydraulic seals, and bushings can expedite the repair process.

However, some instances necessitate professional assistance. If significant mechanical failures are identified, or if electrical repairs seem beyond your expertise, seeking certified technicians is recommended. Finding authorized service providers familiar with Aljon compactors ensures that intricate repairs are managed appropriately, preserving equipment longevity.

Enhancing repair longevity with technology

Modern IoT technologies and monitoring tools facilitate real-time oversight of equipment health. By implementing sensors that collect operational data, operators can identify potential issues before they evolve into costly repairs. Embracing such technologies fosters a proactive approach to maintenance, strengthening operational reliability.

Looking toward the future, trends in compactor repairs may shift towards eco-friendly practices and innovative repair methodologies. As machinery becomes increasingly technologically advanced, staying informed about industry developments will empower operators to maintain their compactors effectively and sustainably.

Contacting experts in Aljon compactor repairs

When in need of repair assistance, locating certified technicians is paramount. Researching repair services that specialize in Aljon compactors ensures highly skilled professionals handle your equipment. Criteria for selection should include certifications, customer reviews, and service warranties, as these factors indicate reliability and quality.

Engaging with the Aljon community through forums and user groups can provide additional insights and support. Sharing experiences and feedback with fellow compactor operators enhances collective knowledge and can lead to improved practices.

For pdfFiller’s FAQs

Below is a list of the most common customer questions. If you can’t find an answer to your question, please don’t hesitate to reach out to us.

How do I make edits in repair of aljon compactor without leaving Chrome?

How can I fill out repair of aljon compactor on an iOS device?

How do I complete repair of aljon compactor on an Android device?

What is repair of aljon compactor?

Who is required to file repair of aljon compactor?

How to fill out repair of aljon compactor?

What is the purpose of repair of aljon compactor?

What information must be reported on repair of aljon compactor?

pdfFiller is an end-to-end solution for managing, creating, and editing documents and forms in the cloud. Save time and hassle by preparing your tax forms online.