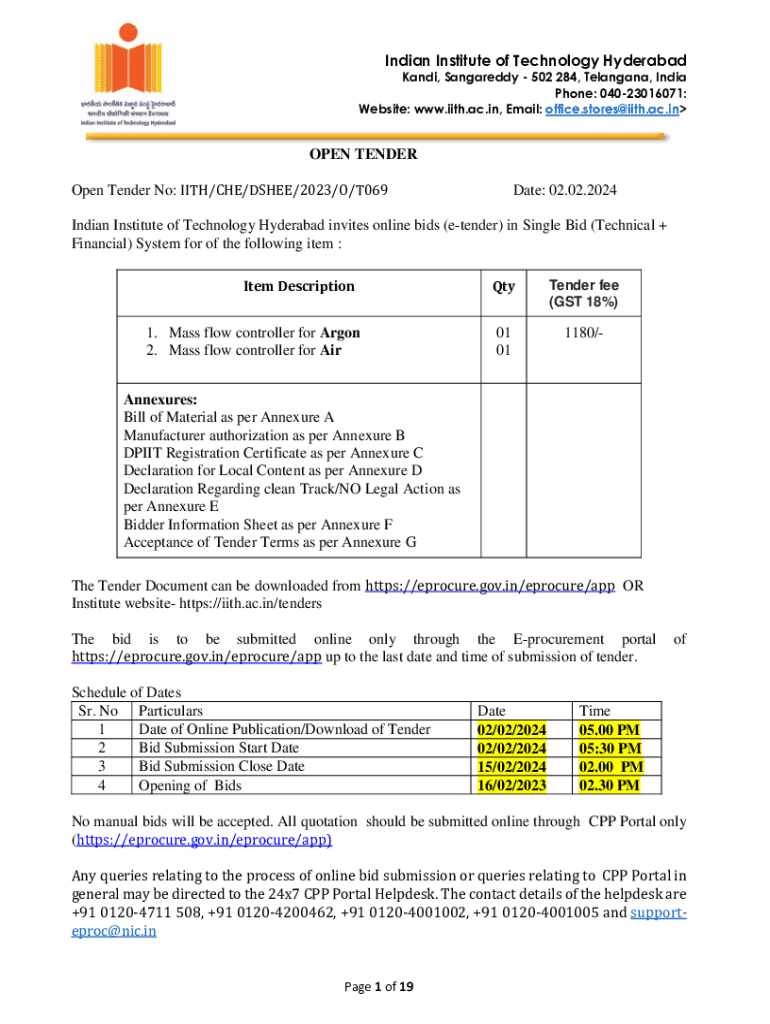

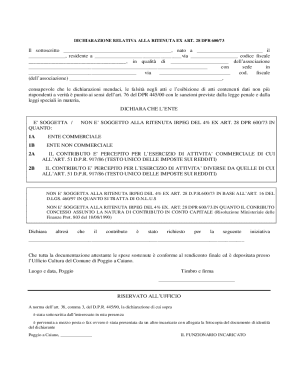

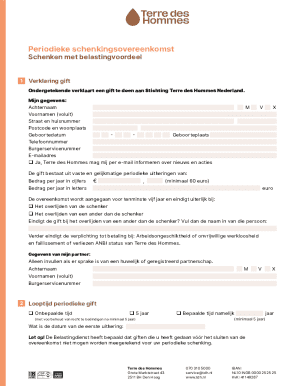

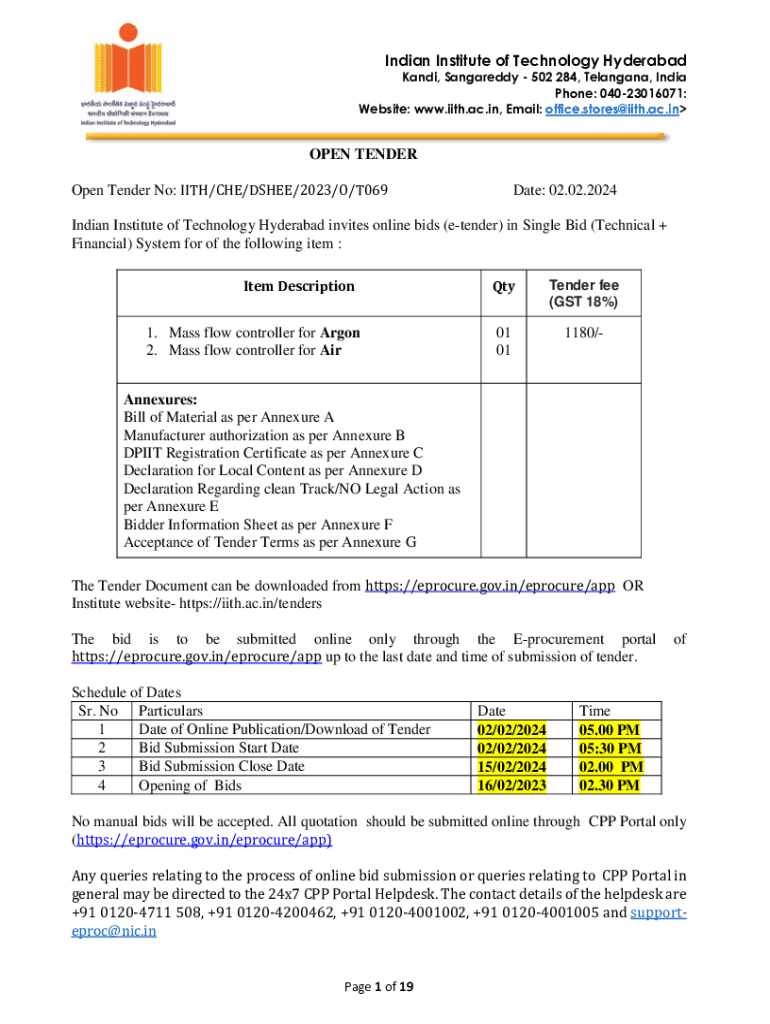

Get the free Mass flow controller for Argon - iith ac

Get, Create, Make and Sign mass flow controller for

Editing mass flow controller for online

Uncompromising security for your PDF editing and eSignature needs

How to fill out mass flow controller for

How to fill out mass flow controller for

Who needs mass flow controller for?

Mass flow controller for form: a comprehensive guide

Understanding mass flow controllers (MFCs)

A mass flow controller (MFC) is an essential device in various industrial and laboratory settings, designed to precisely manage the flow of gases and liquids. By regulating the amount of material allowed to pass through, MFCs ensure consistent process control, thereby enhancing efficiency and product quality. These devices often serve as the backbone of automated systems, paving the way for innovations in manufacturing, research, and beyond.

MFCs come into play in numerous applications, including semiconductor manufacturing, chemical processing, and medical engineering. By accurately managing the flow, they help maintain optimal operation conditions and minimize waste, making them invaluable in high-stakes environments.

Applications of mass flow controllers

Mass flow controllers find applications across various industries, including but not limited to: semiconductor, pharmaceuticals, biotechnology, and food and beverage. In semiconductor manufacturing, for example, precise gas flow is critical for processes such as chemical vapor deposition (CVD) and etching. In pharmaceuticals, maintaining consistent liquid flow rates ensures the accuracy of formulations.

Mechanisms of action

Understanding how a mass flow controller operates is fundamental for its effective application. MFCs utilize a combination of sensors, flow valves, and control electronics to regulate fluid dynamics accurately. The basic principle involves measuring the mass flow rate of the fluid, which is then compared to a desired setpoint, allowing the controller to adjust the flow accordingly.

Key components of MFCs include thermal or differential pressure sensors, electronic control valves, and feedback mechanisms that ensure accuracy. These components work together to achieve a fast and reliable response to changes in flow requirements, making MFCs superior to traditional flow measurement devices.

Mass flow controller vs mass flowmeter

While mass flow controllers and mass flowmeters sound similar, there are crucial distinctions between the two. An MFC not only measures the flow rate but also controls it, whereas a mass flowmeter solely quantifies the amount of substance passing through a point. Choosing between these devices depends on the specific needs of the process. For example, if precise control of flow is needed along with measurement, MFCs are the clear choice.

On the other hand, if merely measuring without the need for regulation, a mass flowmeter suffices. Understanding these differences can significantly impact operational efficiency and cost-effectiveness.

Types of mass flow controllers

There are various types of mass flow controllers, tailored to accommodate different gases and liquids. Each type is optimized for its specific medium, ensuring efficient and safe operation.

MFCs designed for gas applications tend to have features such as lower response times and specialized sensors that can handle the properties of various gases, including inert, corrosive, and flammable types. Liquid mass flow controllers, conversely, often have additional features for liquid viscosity and pressure variations, accommodating substances like water, oils, and chemicals. Each design comes with its challenges and considerations, emphasizing the importance of selecting the right type for the use case.

Choosing the right mass flow controller

Selecting an appropriate mass flow controller involves several key factors that can significantly influence system performance. Essential considerations include the required flow range, accuracy specifications, and pressure ratings of the MFC. Additionally, the materials of construction must be compatible with the specific type of gas or liquid being handled, to avoid issues of corrosion or contamination.

For instance, applications involving corrosive gases call for MFCs made from resistant materials like stainless steel or specialized polymers. Engaging with reputable manufacturers and understanding their product offerings can streamline the selection process.

Leading brands and typical products

Some of the most reputable MFC manufacturers include companies like Brooks Instrument, Bronkhorst, and Mass Flow Online. These brands offer diverse product lines that cater to various sectors and applications, from high-tech semiconductor fabrication to standard industrial processes.

When evaluating different products, it’s essential to compare features, such as ease of integration with existing systems, user interface design, and after-sales support. Customer references and case studies from manufacturers can provide insights into real-world applications and satisfaction.

Technical specifications and design features

The design of mass flow controllers is crucial in determining their performance capabilities. Essential design features include precision and stability in controlling flow rates, which are vital for maintaining product quality and process integrity. Features such as fast response times ensure that any changes in demand are quickly met, reducing waste.

Ensuring regular calibration and diagnostics not only improves accuracy but also prolongs the life of the MFC. Controllers designed with advanced algorithms provide enhanced functionalities and simplify the operations for users.

Product comparison matrix

A solid comparison between popular MFC models can aid in decision-making. Below is a simplified product comparison matrix, serving as a quick reference for key specifications across various brands.

Using a mass flow controller: a step-by-step guide

Installing a mass flow controller effectively requires a clear understanding of both the unit and the operational environment. Guidelines vary depending on the MFC type, but key steps typically include securing the controller in place, ensuring proper alignment with pipes, and connecting to gas or liquid supply lines accurately. Proper installation is paramount to prevent leaks and operational inefficiencies.

After installation, proper setup and calibration processes should be followed. This includes performing pre-operational checks and adjusting the control parameters to meet system requirements, a step that guarantees accurate measurement and control. Additionally, real-time monitoring tools can assist in tracking performance and adjusting flow rates as needed, ensuring optimal operation.

Troubleshooting common issues

Identifying performance problems with mass flow controllers is essential for maintaining operational integrity. Common signs of malfunction may include fluctuating flow rates, inability to reach set points, or unexpected system alarms. To ensure your MFC is operating smoothly, performance should be monitored continuously.

Solutions for common challenges often involve recalibrating the system, checking for blockages in pipes or valves, and ensuring that the sensors are clean and functioning correctly. If these steps do not resolve the issue, consulting the manufacturer or seeking professional help may be necessary to prevent further complications.

Best practices for maintenance and management

Regular maintenance routines are vital to keeping mass flow controllers in optimal condition. Implementing systematic checks can greatly enhance their longevity and functionality. Maintenance should include the inspection of flow valves and sensors, as well as calibration at specified intervals.

Additionally, understanding the operating conditions and ensuring environmental controls can help minimize wear. For instance, protecting MFCs from extreme temperatures or moisture can prolong their effective lifespan. Documenting service histories frequently helps maintain a baseline for performance expectations.

Integrating mass flow controllers with other systems

Mass flow controllers can seamlessly integrate with various automation and control systems. They are often interfaced with PLCs (Programmable Logic Controllers) and SCADA (Supervisory Control and Data Acquisition) systems, allowing for sophisticated control of processes. This integration enhances real-time data collection, enabling operators to monitor system performance actively.

Case studies demonstrate that effective integration of MFCs leads to significant efficiency gains and cost reductions. Industries adopting automated control strategies consistently report quantifiable improvements, such as reduced material waste, energy savings, and improved product quality.

Future trends in mass flow control technology

The future of mass flow controllers is poised for significant advancements, driven by the continuous evolution of technology. Innovations on the horizon include smarter controllers enhanced by IoT (Internet of Things) capabilities, enabling remote monitoring and advanced analytics. These technologies will allow for predictive maintenance and improved energy efficiency.

Mass flow controllers will play a critical role in sustainable practices by enabling efficient resource usage. Emerging trends suggest that MFCs will increasingly be integrated into renewable energy systems, optimizing fuel usage, and minimizing environmental impacts. Case studies highlight implementations where MFCs reduced operational footprints significantly, reinforcing their position as pivotal tools for contemporary manufacturing.

For pdfFiller’s FAQs

Below is a list of the most common customer questions. If you can’t find an answer to your question, please don’t hesitate to reach out to us.

Where do I find mass flow controller for?

How do I edit mass flow controller for online?

How do I edit mass flow controller for on an iOS device?

What is mass flow controller for?

Who is required to file mass flow controller for?

How to fill out mass flow controller for?

What is the purpose of mass flow controller for?

What information must be reported on mass flow controller for?

pdfFiller is an end-to-end solution for managing, creating, and editing documents and forms in the cloud. Save time and hassle by preparing your tax forms online.