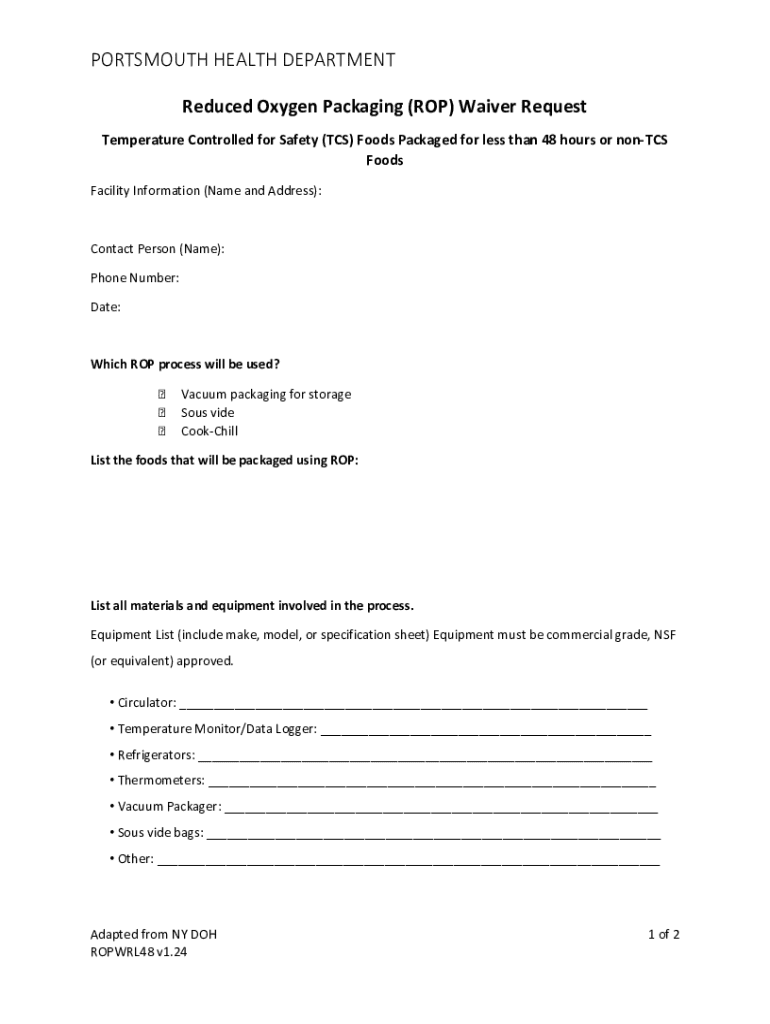

Get the free Reduced Oxygen Packaging (ROP) Waiver Request

Get, Create, Make and Sign reduced oxygen packaging rop

Editing reduced oxygen packaging rop online

Uncompromising security for your PDF editing and eSignature needs

How to fill out reduced oxygen packaging rop

How to fill out reduced oxygen packaging rop

Who needs reduced oxygen packaging rop?

A comprehensive guide to reduced oxygen packaging ROP form

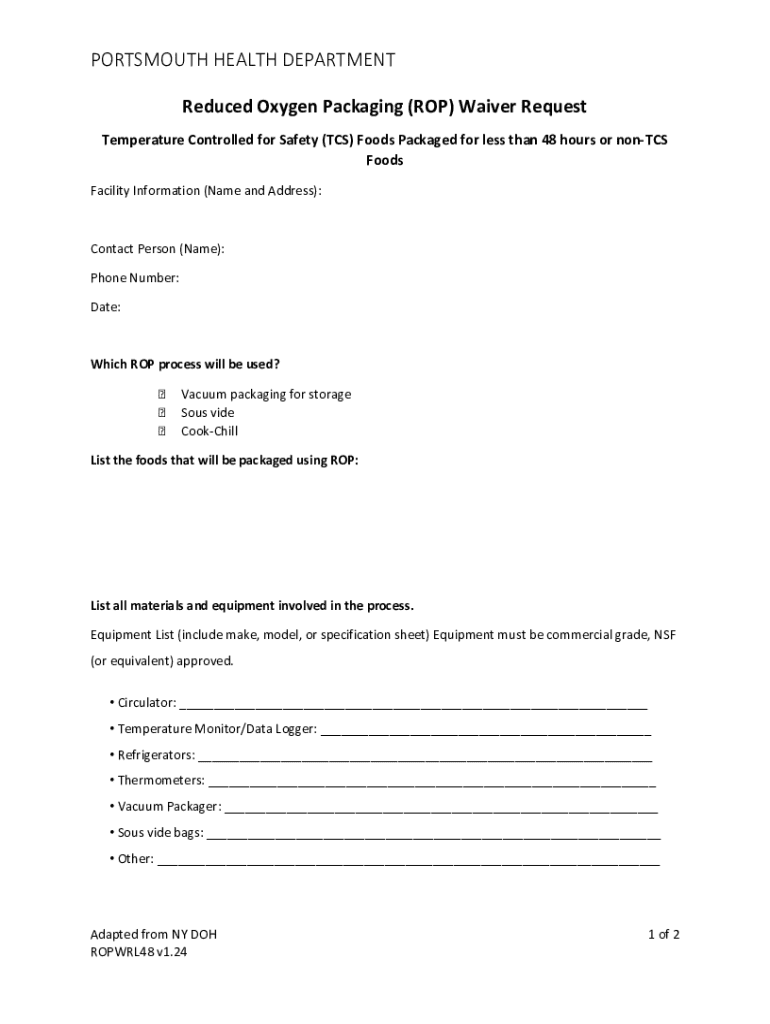

Understanding reduced oxygen packaging

Reduced Oxygen Packaging (ROP) is a method extensively used in the food industry to extend the shelf life of perishables. This technique involves removing the air from the packaging, minimizing oxygen levels that could otherwise lead to spoilage. ROP is critical not just for preserving food quality but also for ensuring safety against microbial growth. Businesses leveraging this method can provide products that stay fresher longer, enhancing customer satisfaction.

Regulatory requirements for ROP

Food safety regulations significantly underscore the importance of ROP practices. The Food and Drug Administration (FDA) and the United States Department of Agriculture (USDA) provide guidelines that businesses must adhere to when utilizing reduced oxygen packaging. For example, ROP items must be monitored for oxygen levels and temperature to comply with safety standards, diminishing risks associated with botulism and other foodborne pathogens.

Additionally, maintaining accurate documentation is essential for compliance. This includes records on packaging methods, product descriptions, shelf-life testing, and storage conditions. Proper documentation not only ensures compliance with health regulations but also plays a significant role in quality assurance.

Step-by-step guide to completing the ROP form

Before you begin filling out the ROP form, it is crucial to prepare. Gather all necessary documentation relating to your product to ensure a smooth process. You should have information regarding the product specifications, monitoring procedures, and compliance requirements ready at hand.

Common challenges in ROP documentation

Filling out the ROP form can present several challenges, especially for those unfamiliar with the requirements. Common errors include incomplete information, mislabeling products, and misinterpretation of storage instructions. These mistakes can lead to rejections of the form by health authorities.

Best practices to avoid such pitfalls involve double-checking entries before submission. Businesses often benefit from utilizing tools like pdfFiller, which offers features for seamless editing and error reduction, allowing users to focus on compliance and less on paperwork.

Interactive tools for managing your ROP documents

pdfFiller revolutionizes document handling with its user-friendly interface and features that enhance productivity. Editing tools allow users to quickly fill forms, add notes, and make corrections with ease. With the ability to access documents from anywhere, teams can efficiently manage their ROP forms, ensuring compliance and organization.

eSigning capabilities within pdfFiller facilitate quick approvals while ensuring compliance with regulations. Users can securely add digital signatures, thereby expediting the review process without compromising safety. Understanding how to effectively utilize these features can streamline your ROP form completion significantly.

Collaboration features for team efficiency

Effective collaboration among team members during the ROP documentation process is essential for success. pdfFiller allows users to share documents easily, making it possible to work together in real time, which can alleviate confusion and enhance productivity.

Moreover, features like notes and comments facilitate open communication on the documents. Teams can leave feedback and track changes, ensuring that everyone is on the same page regarding compliance and quality assurance.

Case studies: Effective ROP implementation

Numerous businesses have reaped significant benefits from implementing ROP forms. For instance, a small seafood company in the Pacific Northwest used ROP to extend their product's freshness and reduce waste. By adopting ROP practices, they not only improved their inventory turnover but also met stringent FDA standards effectively, enhancing their reputation.

Another case involves a dairy distributor that utilized ROP forms to ensure their products remained safe and fresh during transport. As a result, they experienced decreased spoilage and received positive feedback from customers, which directly impacted their bottom line and customer retention rates.

Troubleshooting and FAQs

Common concerns regarding ROP forms frequently arise among businesses. For example, what should you do if your ROP form is rejected? First, review the feedback provided and identify the specific details that need to be amended. If you remain uncertain, consulting a compliance expert can provide clarity.

Additionally, users often have questions about specific instructions related to various products. It's essential to tailor your ROP documentation according to the guidelines specific to each type of food item, as different proteins or dairy products may have unique requirements.

Advanced tips for managing ROP compliance

Embracing technology can significantly enhance how businesses manage ROP compliance. Automation tools can help in tracking expirations and monitoring storage conditions seamlessly. Furthermore, with constant advancements on cloud platforms, businesses should be on the lookout for future innovations that can streamline their processes.

Conducting regular audits on ROP practices is also recommended. This helps in identifying any gaps in compliance, ensuring that businesses remain up-to-date with both FDA and USDA regulations. Keeping processes current will not only enhance food safety but also optimize operational efficiency.

Additional considerations in ROP packing

Different food types may require adjustments to ROP strategies. For instance, while packaging meat products, it’s critical to monitor storage temperatures closely, as they can influence the growth of harmful bacteria. Conversely, seafood may demand expedited processing to minimize spoilage due to its perishable nature.

Looking ahead, trends in reduced oxygen packaging indicate a move toward more sustainable practices, such as biodegradable packaging materials. These innovations not only address environmental concerns but also reflect the growing consumer demand for eco-friendly solutions.

For pdfFiller’s FAQs

Below is a list of the most common customer questions. If you can’t find an answer to your question, please don’t hesitate to reach out to us.

How do I modify my reduced oxygen packaging rop in Gmail?

How can I get reduced oxygen packaging rop?

Can I create an electronic signature for signing my reduced oxygen packaging rop in Gmail?

What is reduced oxygen packaging rop?

Who is required to file reduced oxygen packaging rop?

How to fill out reduced oxygen packaging rop?

What is the purpose of reduced oxygen packaging rop?

What information must be reported on reduced oxygen packaging rop?

pdfFiller is an end-to-end solution for managing, creating, and editing documents and forms in the cloud. Save time and hassle by preparing your tax forms online.