Get the free Instruction Manual for Direct-drive Oil Sealed Rotary Vacuum Pumpmodel Gld-051(s) - ...

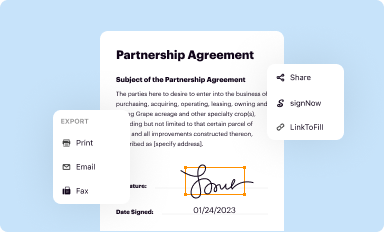

Get, Create, Make and Sign instruction manual for direct-drive

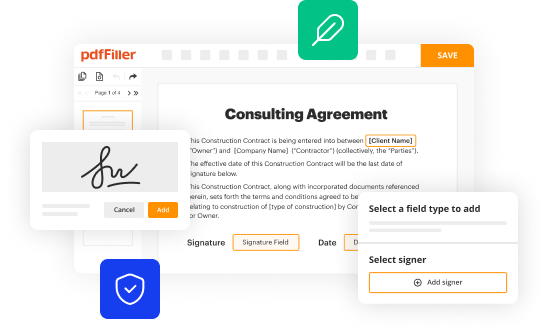

Editing instruction manual for direct-drive online

Uncompromising security for your PDF editing and eSignature needs

How to fill out instruction manual for direct-drive

How to fill out instruction manual for direct-drive

Who needs instruction manual for direct-drive?

Instruction Manual for Direct-Drive Form

Understanding direct-drive systems

Direct-drive systems eliminate the need for gearboxes and belt drives by connecting the motor directly to the load. This setup provides several advantages over traditional systems, including greater energy efficiency, reduced maintenance needs, and improved response times. The elimination of intermediate components also minimizes mechanical losses, allowing for smoother operation and increased durability. Direct-drive systems are quickly becoming the preferred choice in many applications where precision and reliability are paramount.

These systems are utilized in various industries. Notably, in the automotive sector, electric vehicles (EVs) leverage direct-drive technology for optimal torque and efficiency. Similarly, in robotics, direct-drive motors enhance movement precision and reduce wear and tear on mechanical components. Furthermore, manufacturing processes often utilize direct-drive systems for automation, where accuracy and efficiency are critical to production.

Key components of a direct-drive system

At the heart of any direct-drive system is the motor, commonly brushless DC motors, known for their efficiency and low maintenance requirements. These motors directly connect to the load they drive, which can range from small servos to large industrial machines. The absence of gears in these systems reduces backlash and increases torque transmission accuracy, making them ideal for applications necessitating precision.

Control systems are essential for managing the operational parameters of a direct-drive setup. They regulate speed, direction, and torque, ensuring the system operates correctly. Feedback mechanisms, including encoders and sensors, play a crucial role in achieving high efficiency. These components monitor system performance and provide real-time data, enabling precise adjustments to be made automatically, thus enhancing system responsiveness.

Step-by-step instructions for setting up a direct-drive system

Fine-tuning your direct-drive system

To achieve optimal performance, effective calibration techniques are necessary. You can adjust speed and torque outputs through the control system settings. Pay particular attention to the load dynamics, as variations can affect system performance significantly. Regular adjustments based on the load conditions can prevent system failures and enhance longevity.

Performance optimization tips include minimizing friction in moving parts, ensuring proper alignment of components, and maintaining clean electrical connections. Routine inspections of sensors, wiring, and motor condition help to identify potential issues before they turn into major problems. A comprehensive maintenance schedule should be established, advising regular checks and potential downtime for re-calibration and repairs.

Customization and enhancement options

Various customization and enhancement options can be explored to provide advanced functionality. Adding features like smart controls enables remote monitoring and operation via mobile devices or computers, greatly enhancing usability. Wireless connectivity features such as Wi-Fi or Bluetooth can facilitate integration with existing systems, allowing seamless updates and improvements.

Integrating your direct-drive system with existing machinery or software enhances overall productivity. Utilizing API documentation available from manufacturers can facilitate this process, enabling developers to create tailored solutions that communicate with other systems in real time. This integration allows for synchronized operations across multiple systems, increasing efficiency and reducing downtime.

User experiences and case studies

Many users of direct-drive systems have reported significant benefits in their operations. In manufacturing, companies noted increased production efficiency and minimized maintenance costs after implementing direct-drive technologies. Testimonials from robotics enthusiasts highlight improved response times and stability in robotic manipulation tasks, emphasizing how direct-drive systems can enhance design flexibility.

Successful implementations are not limited to small businesses; large enterprises have also leveraged direct-drive technology. For example, automotive manufacturers employing these systems in their electric vehicles have reported an increase in overall vehicle performance and customer satisfaction. Detailed case studies often reveal that engineers are achieving results that were previously unattainable with traditional systems, reinforcing the value of the direct-drive approach.

Interactive tools for managing your direct-drive system

Effective document management is essential for maintaining a direct-drive system. With pdfFiller, users can create, edit, and manage their documents associated with system specifications and maintenance schedules. This cloud-based platform allows individuals and teams to access documents from anywhere, ensuring that essential records are always at hand.

Collaboration features in pdfFiller facilitate ease of use, enabling team members to work together on specific documents, edit in real-time, and electronically sign any necessary forms. Utilizing these capabilities can streamline workflows and enhance overall productivity, allowing teams to focus on system enhancements rather than administrative tasks.

Conclusion: The value of mastering direct-drive systems

Implementing direct-drive systems leads to improvements in efficiency, reliability, and performance, making mastering this technology essential for any team or venture aiming for success. Understanding both the complexities and the operational advantages of direct-drive systems allows teams to optimize their performance and reduce downtime. Streamlined documentation and project management tools from pdfFiller empower users to manage their direct-drive systems effectively, ensuring that they can focus on innovation and growth without getting bogged down in paperwork.

For pdfFiller’s FAQs

Below is a list of the most common customer questions. If you can’t find an answer to your question, please don’t hesitate to reach out to us.

How do I fill out the instruction manual for direct-drive form on my smartphone?

Can I edit instruction manual for direct-drive on an iOS device?

How can I fill out instruction manual for direct-drive on an iOS device?

What is instruction manual for direct-drive?

Who is required to file instruction manual for direct-drive?

How to fill out instruction manual for direct-drive?

What is the purpose of instruction manual for direct-drive?

What information must be reported on instruction manual for direct-drive?

pdfFiller is an end-to-end solution for managing, creating, and editing documents and forms in the cloud. Save time and hassle by preparing your tax forms online.