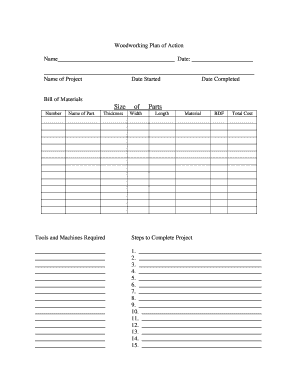

What is Bill Of Materials Example?

The Bill Of Materials Example is a document that provides a detailed breakdown of all the components, parts, and materials required to assemble a product. It serves as a comprehensive inventory list that helps manufacturers and suppliers to keep track of the items needed for production. With a Bill Of Materials Example, companies can ensure that they have all the necessary resources available to produce their products efficiently and accurately.

What are the types of Bill Of Materials Example?

There are various types of Bill Of Materials Example, including:

Single-level Bill Of Materials: This type of Bill Of Materials Example lists all the components required for a single assembly or finished product.

Indented Bill Of Materials: It represents the hierarchical structure of the product, showing the relationship between various sub-assemblies and components.

Modular Bill Of Materials: It focuses on a specific module or sub-assembly of the product, providing a detailed breakdown of the components needed for that specific module.

Manufacturing Bill Of Materials: This type of Bill Of Materials Example includes all the components required for production, including raw materials, sub-assemblies, and purchased parts.

How to complete Bill Of Materials Example

Completing a Bill Of Materials Example involves the following steps:

01

Identify the product: Begin by clearly defining the product for which you need to create the Bill Of Materials Example.

02

List the components: Make a comprehensive list of all the components, parts, and materials required for the assembly of the product.

03

Specify quantities: Determine the quantities needed for each component, considering factors such as waste, scrap, and extra parts for replacements.

04

Organize the hierarchy: If applicable, arrange the components in a hierarchical structure, indicating the relationships between sub-assemblies and components.

05

Document details: Provide additional details for each component, such as part numbers, descriptions, vendors, and specifications.

06

Review and validate: Carefully review the Bill Of Materials Example to ensure accuracy and completeness, making any necessary revisions or updates.

07

Share and collaborate: Once completed, share the Bill Of Materials Example with relevant stakeholders, such as manufacturers, suppliers, and team members, for collaboration and feedback.

pdfFiller empowers users to create, edit, and share documents online. Offering unlimited fillable templates and powerful editing tools, pdfFiller is the only PDF editor users need to get their documents done.