What is how to create a bill of materials?

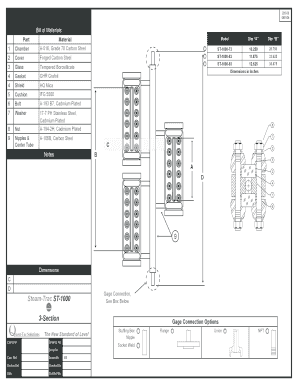

A bill of materials (BOM) is a comprehensive list of all components and materials required to build or manufacture a product. It includes detailed information such as part numbers, descriptions, quantities, and additional specifications. This document plays a crucial role in the production process as it helps ensure that all necessary materials are available and that the product is built correctly.

What are the types of how to create a bill of materials?

There are several types of bills of materials, each serving a specific purpose in different industries. The most common types include:

Engineering BOM (EBOM): This type of BOM focuses on the design and engineering aspects of a product. It includes all the components needed to create the final product according to the specifications.

Manufacturing BOM (MBOM): The MBOM lists all the materials and components required to manufacture a product. It includes information such as the quantity, location, and cost of each item.

Sales BOM (SBOM): SBOM is used by the sales team to provide customers with a simplified version of the BOM. It includes only the essential components and materials needed for the customer to understand the product.

Service BOM (Service BOM): Service BOM is specific to the maintenance and repair of a product. It includes all the spare parts and tools required for servicing the product.

How to complete how to create a bill of materials

To create a bill of materials, follow these steps:

01

Identify and list all components: Start by identifying all the components and materials required for the product.

02

Gather detailed information: Collect detailed information about each component, including part numbers, descriptions, quantities, and additional specifications.

03

Organize the BOM structure: Determine the structure of the bill of materials based on the product's assembly hierarchy and dependencies.

04

Define the BOM versioning system: Establish a clear versioning system to track changes and updates to the BOM over time.

05

Review and validate the BOM: Double-check all the information in the BOM for accuracy and completeness. Ensure that the BOM aligns with the product design and requirements.

06

Share and collaborate: Utilize pdfFiller, an online platform that empowers users to create, edit, and share documents online. With unlimited fillable templates and powerful editing tools, pdfFiller is the ideal solution for generating and managing bills of materials efficiently.

By following these steps and leveraging pdfFiller's capabilities, you can create a comprehensive and accurate bill of materials to streamline your production process.