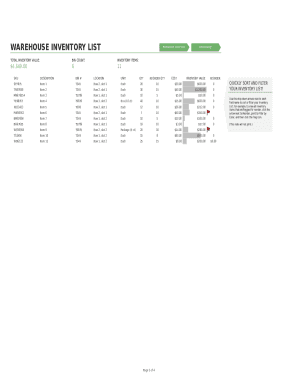

What is Warehouse Inventory?

Warehouse inventory refers to the total amount of goods and products that a warehouse holds at a specific point in time. It includes all items, materials, and products stored in the warehouse awaiting distribution or use.

What are the types of Warehouse Inventory?

There are several types of warehouse inventory, including:

Raw materials inventory

Work in progress inventory

Finished goods inventory

MRO (Maintenance, Repair, and Operating supplies) inventory

Transit inventory

Anticipation inventory

How to complete Warehouse Inventory

Completing warehouse inventory efficiently and accurately is crucial for ensuring smooth operations. Here are some steps to help you complete warehouse inventory:

01

Organize and categorize items in the warehouse

02

Use inventory management software for tracking

03

Conduct regular cycle counts to maintain accuracy

04

Implement barcode scanning for faster inventory checks

05

Train warehouse staff on proper inventory procedures

pdfFiller empowers users to create, edit, and share documents online. Offering unlimited fillable templates and powerful editing tools, pdfFiller is the only PDF editor users need to get their documents done.

Video Tutorial How to Fill Out Warehouse Inventory

Thousands of positive reviews can’t be wrong

Read more or give pdfFiller a try to experience the benefits for yourself

Questions & answers

What are the 6 types of inventory?

The 6 Main classifications of inventory transit inventory. buffer inventory. anticipation inventory. decoupling inventory. cycle inventory. MRO goods inventory.

What are the 5 types of inventory?

Companies should pay equal attention to all five inventory types: raw materials inventory, work-in-progress (WIP) inventory, maintenance, repair, and operating (MRO) inventory, finished goods inventory, and packing materials inventory.

What is a warehouse inventory?

Warehouse inventory includes the products, raw materials, work-in-process goods and finished goods that make up the inventory that is or will be for sale by a company.

What are the 4 main steps in inventory management?

To manage your inventory effectively, you can follow a 4 step process: Assess what you have now. Review what you had. Analyse sales. Identify items to repurchase or retire.

How is inventory managed in a warehouse?

An inventory management system (IMS) tracks all the stock in every warehouse and documents which warehouse stores it. A warehouse management system (WMS) tracks where each type of stock resides within a warehouse. The two solutions often work together. Track all inventory across all locations.

How do warehouses keep track of inventory?

Barcodes With a barcode system, each item has a label that links to information such as description, location, and price. These labels are scanned with barcode scanners to quickly track items as they move in and out of the warehouse and automatically update inventory levels.