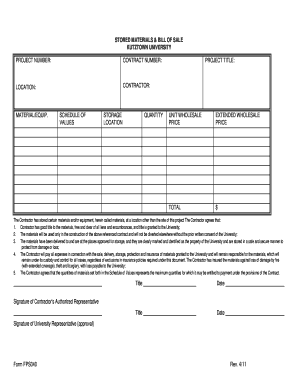

What is Sample Bill Of Materials?

A Sample Bill of Materials (BOM) is a comprehensive list of all the materials, components, and parts needed to manufacture a product. It serves as a roadmap for the production process, ensuring that all necessary items are included and accounted for. The BOM provides details such as part descriptions, quantities, and specifications, allowing manufacturers to effectively plan and manage their production workflow.

What are the types of Sample Bill Of Materials?

There are several types of Sample Bill of Materials commonly used in manufacturing processes. These include:

Engineering BOM (EBOM): This type of BOM focuses on the design and engineering aspects of a product. It includes detailed information about the product's components, sub-assemblies, and specifications.

Manufacturing BOM (MBOM): The MBOM provides instructions for the production process, including details on how to assemble the product and the specific materials required at each stage.

Sales BOM (SBOM): The SBOM is used for pricing and sales purposes. It includes information such as pricing, discounts, and delivery timelines.

Service BOM (Service Bill of Materials): This type of BOM is used for maintenance and repair purposes. It includes a list of all the components and parts needed for servicing or repairing a product.

How to complete Sample Bill Of Materials

Completing a Sample Bill of Materials involves several steps to ensure accuracy and efficiency. Here's a step-by-step guide:

01

Identify and gather all the necessary information about the product and its components. This includes part numbers, descriptions, quantities, and specifications.

02

Organize the information in a structured format, either using a spreadsheet or specialized BOM software.

03

Verify the accuracy of the information by cross-checking it with other relevant documents, such as engineering drawings or product specifications.

04

Review and update the BOM regularly to reflect any changes or updates in the product design or manufacturing process.

05

Share the completed BOM with all stakeholders, including suppliers, manufacturers, and other relevant parties.

06

Utilize software tools like pdfFiller to create, edit, and share the Sample Bill of Materials online, streamlining the document management process.

pdfFiller empowers users to create, edit, and share documents online. Offering unlimited fillable templates and powerful editing tools, pdfFiller is the only PDF editor users need to get their documents done.