Get the free Risk Assessment of Metal Vapor Arcing - ntrs nasa

Show details

This document describes a method and system for assessing the risk of metal vapor arcing in components, particularly in spacecraft systems. It outlines the variables involved in determining risk and

We are not affiliated with any brand or entity on this form

Get, Create, Make and Sign risk assessment of metal

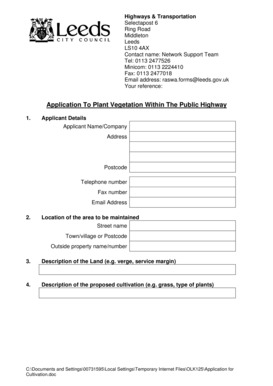

Edit your risk assessment of metal form online

Type text, complete fillable fields, insert images, highlight or blackout data for discretion, add comments, and more.

Add your legally-binding signature

Draw or type your signature, upload a signature image, or capture it with your digital camera.

Share your form instantly

Email, fax, or share your risk assessment of metal form via URL. You can also download, print, or export forms to your preferred cloud storage service.

How to edit risk assessment of metal online

To use the services of a skilled PDF editor, follow these steps:

1

Create an account. Begin by choosing Start Free Trial and, if you are a new user, establish a profile.

2

Prepare a file. Use the Add New button to start a new project. Then, using your device, upload your file to the system by importing it from internal mail, the cloud, or adding its URL.

3

Edit risk assessment of metal. Rearrange and rotate pages, add and edit text, and use additional tools. To save changes and return to your Dashboard, click Done. The Documents tab allows you to merge, divide, lock, or unlock files.

4

Get your file. Select the name of your file in the docs list and choose your preferred exporting method. You can download it as a PDF, save it in another format, send it by email, or transfer it to the cloud.

With pdfFiller, dealing with documents is always straightforward. Try it now!

Uncompromising security for your PDF editing and eSignature needs

Your private information is safe with pdfFiller. We employ end-to-end encryption, secure cloud storage, and advanced access control to protect your documents and maintain regulatory compliance.

How to fill out risk assessment of metal

How to fill out Risk Assessment of Metal Vapor Arcing

01

Identify the materials and equipment involved in the metal vapor arcing process.

02

Define the potential hazards associated with metal vapor arcing, such as exposure to hazardous materials and electric shock.

03

Evaluate the likelihood of each hazard occurring and its potential impact on health and safety.

04

Implement control measures to mitigate identified risks, including engineering controls, personal protective equipment, and safe work procedures.

05

Document the findings in the risk assessment form, ensuring all relevant details are included.

06

Review and update the risk assessment regularly or when changes occur in the process or equipment.

Who needs Risk Assessment of Metal Vapor Arcing?

01

Employees working with electrical equipment that may involve metal vapor arcing.

02

Safety officers responsible for workplace safety and compliance.

03

Management and supervisors overseeing operations involving potential metal vapor arcing.

04

Health and safety committees focusing on risk management in the workplace.

Fill

form

: Try Risk Free

People Also Ask about

What is the risk of electrical arc?

Risks Associated with Arc Flash Hazards Severe Burns: The intense heat generated by an arc flash can cause severe burns, even from a distance. Temperatures can reach up to 35,000°F (19,427°C), which is hotter than the surface of the sun.

Which 3 factors does an arc flash risk assessment determine?

Three factors determine the severity of an arc flash injury: Proximity of the worker to the hazard , Temperature and Time for the circuit to break.

What are the effects of electrical arcing?

If a circuit has enough current and voltage to sustain an arc formed outside of a switching device, the arc can cause damage to equipment such as melting of conductors, destruction of insulation, and fire. An arc flash describes an explosive electrical event that presents a hazard to people and equipment.

What are the OSHA requirements for arc flash?

This paragraph requires employers to: (1) Assess the workplace for flame and electric-arc hazards (paragraph (l)(8)(i)); (2) estimate the available heat energy from electric arcs to which employees would be exposed (paragraph (l)(8)(ii)); (3) ensure that employees wear clothing that will not melt, or ignite and

What are the injuries of electrical arc?

Arc flash injury can cause severe personal injury including external burns, internal burns, intoxication from inhaling hot gases and vaporised metal, hearing damage, eye damage and blindness from the ultraviolet light of the flash, as well as many other devastating injuries.

What is the risk assessment for welding activity?

Risk Assessment of Welding. The welding risk assessment must take account of the type of welding, the material being welded, the welding gas used and the electrode or welding rod, in addition to the location, other welding activities, ventilation and the work practices of the welder.

What are the dangers of arc fault?

Arc-eye occurs when the surface of the eye is exposed to excessive ultraviolet (UV) radiation—usually when an arc is accidentally struck while the welding helmet is in the up position or the eyes are otherwise unprotected. Long-term over-exposure to arc radiation is linked to retinal burns, cataracts and skin cancer.

What is the risk assessment for NFPA 70E?

The risk assessment procedure should identify hazards, assess risks and implement risk control ing to the hierarchy of risk control methods. To safely work on electrical equipment, all risks must be assessed in order to minimize the potential hazards to the worker.

What is the risk assessment for arc flash?

An arc flash risk assessment is a calculation performed by a licensed professional engineer to determine the incident energy found at each location which determines the arc flash boundaries and what personal protective equipment (PPE) must be used by the employee.

For pdfFiller’s FAQs

Below is a list of the most common customer questions. If you can’t find an answer to your question, please don’t hesitate to reach out to us.

What is Risk Assessment of Metal Vapor Arcing?

Risk Assessment of Metal Vapor Arcing involves identifying, evaluating, and mitigating the potential hazards associated with metal vapor arcing, which can occur during electrical discharges in certain environments, leading to risks such as explosions, fires, or equipment damage.

Who is required to file Risk Assessment of Metal Vapor Arcing?

Individuals or organizations that operate equipment or facilities where metal vapor arcing may occur are required to file a Risk Assessment. This typically includes manufacturers, maintenance personnel, and safety officers.

How to fill out Risk Assessment of Metal Vapor Arcing?

To fill out the Risk Assessment, stakeholders need to gather relevant data on equipment specifications, operating conditions, past incidents, potential hazardous materials, and procedures for risk mitigation. This information should be structured into specific sections of the risk assessment form.

What is the purpose of Risk Assessment of Metal Vapor Arcing?

The purpose of the Risk Assessment is to ensure the safety of personnel and assets by identifying potential risks associated with metal vapor arcing and implementing strategies to minimize or eliminate these risks.

What information must be reported on Risk Assessment of Metal Vapor Arcing?

The report must include details such as risk identification, analysis of potential hazards, evaluation of existing controls, recommendations for improvements, and an action plan for risk mitigation.

Fill out your risk assessment of metal online with pdfFiller!

pdfFiller is an end-to-end solution for managing, creating, and editing documents and forms in the cloud. Save time and hassle by preparing your tax forms online.

Risk Assessment Of Metal is not the form you're looking for?Search for another form here.

Relevant keywords

Related Forms

If you believe that this page should be taken down, please follow our DMCA take down process

here

.

This form may include fields for payment information. Data entered in these fields is not covered by PCI DSS compliance.