Get the free Qualified Materials Approval Procedures

Show details

This document outlines the procedures for manufacturers to request approval of non-electronic components for inclusion in the NJDOT Bureau of ITS Engineering’s Qualified Products List (QPL). It

We are not affiliated with any brand or entity on this form

Get, Create, Make and Sign qualified materials approval procedures

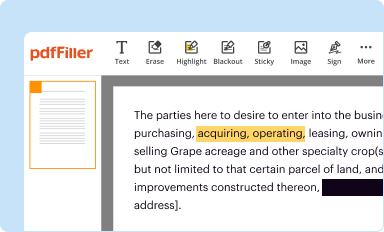

Edit your qualified materials approval procedures form online

Type text, complete fillable fields, insert images, highlight or blackout data for discretion, add comments, and more.

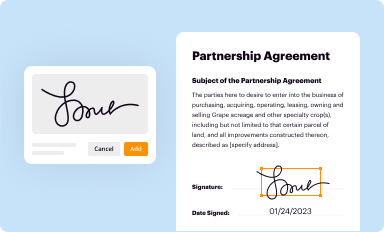

Add your legally-binding signature

Draw or type your signature, upload a signature image, or capture it with your digital camera.

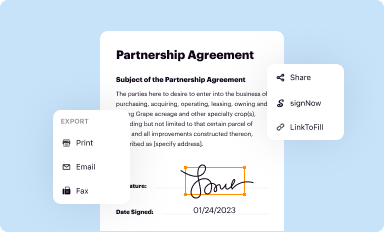

Share your form instantly

Email, fax, or share your qualified materials approval procedures form via URL. You can also download, print, or export forms to your preferred cloud storage service.

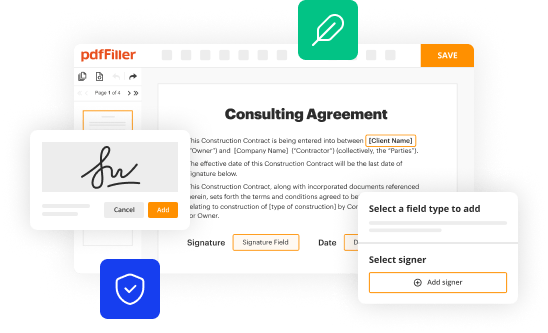

Editing qualified materials approval procedures online

Follow the guidelines below to use a professional PDF editor:

1

Check your account. If you don't have a profile yet, click Start Free Trial and sign up for one.

2

Upload a file. Select Add New on your Dashboard and upload a file from your device or import it from the cloud, online, or internal mail. Then click Edit.

3

Edit qualified materials approval procedures. Rearrange and rotate pages, insert new and alter existing texts, add new objects, and take advantage of other helpful tools. Click Done to apply changes and return to your Dashboard. Go to the Documents tab to access merging, splitting, locking, or unlocking functions.

4

Save your file. Select it in the list of your records. Then, move the cursor to the right toolbar and choose one of the available exporting methods: save it in multiple formats, download it as a PDF, send it by email, or store it in the cloud.

pdfFiller makes dealing with documents a breeze. Create an account to find out!

Uncompromising security for your PDF editing and eSignature needs

Your private information is safe with pdfFiller. We employ end-to-end encryption, secure cloud storage, and advanced access control to protect your documents and maintain regulatory compliance.

How to fill out qualified materials approval procedures

How to fill out Qualified Materials Approval Procedures

01

Obtain the Qualified Materials Approval Procedures document from the relevant authority.

02

Review the materials and specifications required for approval.

03

Complete the application form with accurate information about the materials.

04

Gather all supporting documentation, including test results and certifications.

05

Submit the application along with the supporting documents to the designated authority.

06

Pay any required fees for processing the application.

07

Await feedback or request for additional information from the authority.

08

Make any necessary revisions based on feedback received.

09

Once approved, ensure to keep the approval documentation for future reference.

Who needs Qualified Materials Approval Procedures?

01

Manufacturers looking to certify their materials for use in various projects.

02

Contractors needing to comply with regulatory requirements for material usage.

03

Engineers and architects who require approved materials for design and construction.

04

Quality control inspectors responsible for verifying material compliance.

Fill

form

: Try Risk Free

People Also Ask about

What is the process of material approval?

Approval of material, product, process is the confirmation by sealing and/or by the RS document of the compliance of material, product, process with the RS requirements given the positive results of their certification.

What is the process of approval process?

Approval processes maintain efficiency and transparency by embedding control and oversight into organizational operations. They provide a framework for coordinated decision-making across different levels and departments, enabling a streamlined process that reduces delays and fosters collaboration.

What is the material approval request?

Material's approval may be by testing or specific evaluation of the product against the specifications as stated in the Standard Specifications or Contract documents. This must be performed before the materials are incorporated into the project and should be done prior to the material's arriving on the jobsite.

What is the material approval request?

Material's approval may be by testing or specific evaluation of the product against the specifications as stated in the Standard Specifications or Contract documents. This must be performed before the materials are incorporated into the project and should be done prior to the material's arriving on the jobsite.

What is the process of document approval?

Document approval processes tell the system who needs to approve a new document or a revision to an existing document. You can select as many or as few approvers as you need to approve each document. You can create approval processes for new documents / major revisions and minor revisions.

What is the process for approval of submittals?

The subcontractor submits the submittal to the general contractor, the general contractor reviews it and submits it to the construction manager, the construction manager reviews it and sends it to the engineer, the engineer reviews it and sends it to the architect, the architect sends changes back to the construction

For pdfFiller’s FAQs

Below is a list of the most common customer questions. If you can’t find an answer to your question, please don’t hesitate to reach out to us.

What is Qualified Materials Approval Procedures?

Qualified Materials Approval Procedures are a systematic process used to evaluate and approve materials for use in specific applications, ensuring they meet required standards and specifications.

Who is required to file Qualified Materials Approval Procedures?

Manufacturers and suppliers of materials seeking approval for use in regulated industries or projects typically are required to file Qualified Materials Approval Procedures.

How to fill out Qualified Materials Approval Procedures?

To fill out Qualified Materials Approval Procedures, applicants must provide detailed information about the materials, including technical specifications, testing results, and compliance with relevant standards.

What is the purpose of Qualified Materials Approval Procedures?

The purpose of Qualified Materials Approval Procedures is to ensure that materials used in construction or manufacturing meet safety, performance, and regulatory standards, thereby reducing risks in projects.

What information must be reported on Qualified Materials Approval Procedures?

Information that must be reported includes material specifications, test data, compliance certificates, and any other relevant documentation that demonstrates the material's suitability for the intended use.

Fill out your qualified materials approval procedures online with pdfFiller!

pdfFiller is an end-to-end solution for managing, creating, and editing documents and forms in the cloud. Save time and hassle by preparing your tax forms online.

Qualified Materials Approval Procedures is not the form you're looking for?Search for another form here.

Relevant keywords

Related Forms

If you believe that this page should be taken down, please follow our DMCA take down process

here

.

This form may include fields for payment information. Data entered in these fields is not covered by PCI DSS compliance.