Get the free The Application of Lean Tools and 5S to Improve a Production Area - www2 uwstout

Show details

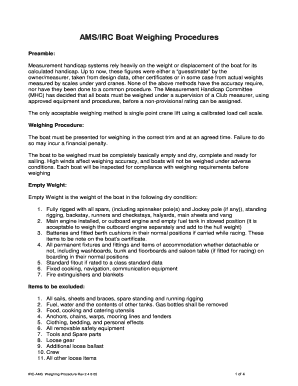

This research report aims to reduce the square footage and improve the efficiency of Department 1A by applying lean tools and the 5S methodology. It details the methodology, findings, and outcomes

We are not affiliated with any brand or entity on this form

Get, Create, Make and Sign form application of lean

Edit your form application of lean form online

Type text, complete fillable fields, insert images, highlight or blackout data for discretion, add comments, and more.

Add your legally-binding signature

Draw or type your signature, upload a signature image, or capture it with your digital camera.

Share your form instantly

Email, fax, or share your form application of lean form via URL. You can also download, print, or export forms to your preferred cloud storage service.

How to edit form application of lean online

Here are the steps you need to follow to get started with our professional PDF editor:

1

Create an account. Begin by choosing Start Free Trial and, if you are a new user, establish a profile.

2

Prepare a file. Use the Add New button to start a new project. Then, using your device, upload your file to the system by importing it from internal mail, the cloud, or adding its URL.

3

Edit form application of lean. Add and replace text, insert new objects, rearrange pages, add watermarks and page numbers, and more. Click Done when you are finished editing and go to the Documents tab to merge, split, lock or unlock the file.

4

Save your file. Select it from your records list. Then, click the right toolbar and select one of the various exporting options: save in numerous formats, download as PDF, email, or cloud.

pdfFiller makes dealing with documents a breeze. Create an account to find out!

Uncompromising security for your PDF editing and eSignature needs

Your private information is safe with pdfFiller. We employ end-to-end encryption, secure cloud storage, and advanced access control to protect your documents and maintain regulatory compliance.

How to fill out form application of lean

How to fill out The Application of Lean Tools and 5S to Improve a Production Area

01

Define the objectives of the application of Lean Tools and 5S.

02

Assemble a team with representation from all relevant departments.

03

Conduct a current state analysis of the production area.

04

Identify waste and inefficiencies through observation and data collection.

05

Develop a plan to implement 5S (Sort, Set in order, Shine, Standardize, Sustain).

06

Train team members on Lean principles and 5S methodology.

07

Implement 5S in the production area step-by-step.

08

Measure the impact of Lean and 5S implementation using key performance indicators (KPIs).

09

Review and adjust the strategy based on feedback and results.

10

Establish a routine for continuous improvement and sustainment of Lean practices.

Who needs The Application of Lean Tools and 5S to Improve a Production Area?

01

Manufacturing companies seeking to improve efficiency.

02

Organizations aiming to reduce waste in production processes.

03

Teams needing to enhance workplace organization and cleanliness.

04

Managers looking to foster a culture of continuous improvement.

05

Any business that wants to maximize productivity and quality.

Fill

form

: Try Risk Free

People Also Ask about

What are the 5 Lean manufacturing tools?

What Are Lean Tools? Lean ToolsSummary Just-in-Time (JIT) On-demand system of production Value Stream Mapping Analyzing and optimizing a process Overall Equipment Effectiveness (OEE) Measure of productive time Plan-Do-Check-Act (PDCA) Method to manage change3 more rows • Jun 30, 2021

Is 5S the same as lean?

While 5S is focused on organizing the workplace and facility, Lean (often called Lean manufacturing) is a method used to identify and eliminate waste from a manufacturing process. Lean aims to remove anything from the production process that does not add value to the end product or service the customer purchases.

What are the 5S in lean tool?

The 5S pillars, Sort (Seiri), Set in Order (Seiton), Shine (Seiso), Standardize (Seiketsu), and Sustain (Shitsuke), provide a methodology for organizing, cleaning, developing, and sustaining a productive work environment.

What are the 5S used in lean tools?

The 5S pillars, Sort (Seiri), Set in Order (Seiton), Shine (Seiso), Standardize (Seiketsu), and Sustain (Shitsuke), provide a methodology for organizing, cleaning, developing, and sustaining a productive work environment.

What is the application of 5S in industry?

5S is a simple way to improve your workplace productivity, safety, cleanliness, output quality, and team morale. The 5S approach is rooted in lean production principles, and it is designed to be cost-effectively implemented using the resources you already have in place.

What is needed in a lean 5S toolkit?

A successful 5S program requires effective visual communication, which includes the following: Labels for storage bins, shelving, and tools will help workers identify items and put them back where they belong. Procedure labels can communicate procedural changes and help workers complete tasks correctly, every time.

What are the 5 steps of lean production?

The 5 Key Lean Manufacturing Principles Identifying Value from the Client's POV. What do your customers value? Identify the Value Stream. The value stream consists of what the client values from their perspective. Achieving Flow of Work Processes. Using Pull Planning and Scheduling. Continuous Improvement & Perfection.

For pdfFiller’s FAQs

Below is a list of the most common customer questions. If you can’t find an answer to your question, please don’t hesitate to reach out to us.

What is The Application of Lean Tools and 5S to Improve a Production Area?

The Application of Lean Tools and 5S is a systematic approach aimed at enhancing productivity and efficiency in a production area by eliminating waste, improving organization, and establishing standardized work practices.

Who is required to file The Application of Lean Tools and 5S to Improve a Production Area?

Typically, line managers, production supervisors, and quality assurance personnel are responsible for filing the application, as they are directly involved in the production processes and improvement initiatives.

How to fill out The Application of Lean Tools and 5S to Improve a Production Area?

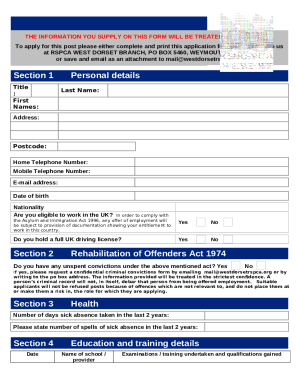

To fill out the application, one should assess the current state of the production area, identify areas of waste, outline proposed changes, document existing conditions, and include measurable goals for improvement.

What is the purpose of The Application of Lean Tools and 5S to Improve a Production Area?

The purpose is to create a more efficient work environment by standardizing procedures, reducing waste, improving safety, and ultimately enhancing overall productivity and quality in the production process.

What information must be reported on The Application of Lean Tools and 5S to Improve a Production Area?

The application must include details such as the current state analysis, identified waste, proposed improvements, responsible personnel, timelines for implementation, and metrics for measuring success.

Fill out your form application of lean online with pdfFiller!

pdfFiller is an end-to-end solution for managing, creating, and editing documents and forms in the cloud. Save time and hassle by preparing your tax forms online.

Form Application Of Lean is not the form you're looking for?Search for another form here.

Relevant keywords

Related Forms

If you believe that this page should be taken down, please follow our DMCA take down process

here

.

This form may include fields for payment information. Data entered in these fields is not covered by PCI DSS compliance.