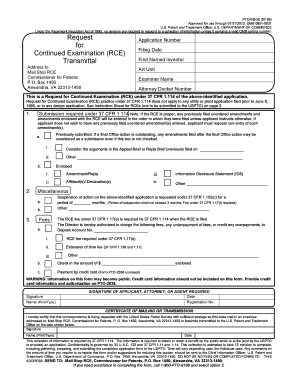

Get the free Mechanical Purity

Show details

Oklahoma Crop Improvement Association

Order Form for Labels

Date:

Name:

Shipping Address

City:State:Zip Code:Phone Number:Variety

Mechanical Purity

Inert Matter

Other Crop Seed

Weed Seed

Noxious WeedsCrop

Germ.

Hard

We are not affiliated with any brand or entity on this form

Get, Create, Make and Sign mechanical purity

Edit your mechanical purity form online

Type text, complete fillable fields, insert images, highlight or blackout data for discretion, add comments, and more.

Add your legally-binding signature

Draw or type your signature, upload a signature image, or capture it with your digital camera.

Share your form instantly

Email, fax, or share your mechanical purity form via URL. You can also download, print, or export forms to your preferred cloud storage service.

How to edit mechanical purity online

To use our professional PDF editor, follow these steps:

1

Log in. Click Start Free Trial and create a profile if necessary.

2

Upload a document. Select Add New on your Dashboard and transfer a file into the system in one of the following ways: by uploading it from your device or importing from the cloud, web, or internal mail. Then, click Start editing.

3

Edit mechanical purity. Text may be added and replaced, new objects can be included, pages can be rearranged, watermarks and page numbers can be added, and so on. When you're done editing, click Done and then go to the Documents tab to combine, divide, lock, or unlock the file.

4

Get your file. Select the name of your file in the docs list and choose your preferred exporting method. You can download it as a PDF, save it in another format, send it by email, or transfer it to the cloud.

pdfFiller makes dealing with documents a breeze. Create an account to find out!

Uncompromising security for your PDF editing and eSignature needs

Your private information is safe with pdfFiller. We employ end-to-end encryption, secure cloud storage, and advanced access control to protect your documents and maintain regulatory compliance.

How to fill out mechanical purity

How to fill out mechanical purity

01

To fill out mechanical purity, follow these steps:

02

Gather all the necessary information about the mechanical process or system that you want to assess for purity.

03

Start by identifying the different components or elements involved in the mechanical process.

04

Determine the criteria or standards that define purity in the context of the mechanical process. This could include factors such as absence of contaminants, proper functioning of components, and adherence to specifications.

05

Evaluate each component or element against the defined criteria for purity. Assess their performance, condition, and compliance with standards.

06

Document your findings for each component or element, noting any deviations or deficiencies in terms of purity.

07

Provide recommendations or corrective actions for improving the purity of the mechanical process, if necessary.

08

Review and validate the filled out mechanical purity assessment to ensure accuracy and completeness.

09

Communicate the findings and recommendations to the relevant stakeholders or responsible parties.

10

Periodically reassess the mechanical purity to maintain or improve the quality of the mechanical process.

11

Update the filled out mechanical purity assessment as needed based on any changes or improvements made.

Who needs mechanical purity?

01

Mechanical purity is needed by various individuals or entities involved in mechanical processes, including:

02

- Engineers and designers who need to ensure the quality and reliability of mechanical systems or components.

03

- Manufacturers and suppliers who want to meet industry standards and regulations for mechanical purity.

04

- Maintenance and inspection teams responsible for identifying and addressing any impurities or deficiencies in mechanical systems.

05

- Quality control departments that monitor and evaluate the purity of mechanical processes for overall product integrity.

06

- Regulatory bodies or governing authorities that enforce standards and regulations related to mechanical purity.

07

- Researchers and scientists involved in studying the performance and efficiency of mechanical systems.

08

- Any individual or organization that relies on mechanical processes for their operations, safety, or well-being.

Fill

form

: Try Risk Free

For pdfFiller’s FAQs

Below is a list of the most common customer questions. If you can’t find an answer to your question, please don’t hesitate to reach out to us.

Where do I find mechanical purity?

The premium pdfFiller subscription gives you access to over 25M fillable templates that you can download, fill out, print, and sign. The library has state-specific mechanical purity and other forms. Find the template you need and change it using powerful tools.

How do I edit mechanical purity online?

With pdfFiller, the editing process is straightforward. Open your mechanical purity in the editor, which is highly intuitive and easy to use. There, you’ll be able to blackout, redact, type, and erase text, add images, draw arrows and lines, place sticky notes and text boxes, and much more.

Can I edit mechanical purity on an iOS device?

You certainly can. You can quickly edit, distribute, and sign mechanical purity on your iOS device with the pdfFiller mobile app. Purchase it from the Apple Store and install it in seconds. The program is free, but in order to purchase a subscription or activate a free trial, you must first establish an account.

What is mechanical purity?

Mechanical purity refers to the extent to which a mechanical component is free from contaminants and impurities, ensuring that it meets specific quality and performance standards.

Who is required to file mechanical purity?

Manufacturers and distributors of mechanical components are typically required to file mechanical purity to demonstrate compliance with industry standards and regulations.

How to fill out mechanical purity?

To fill out mechanical purity, a designated form is usually required, detailing the specifications, testing results, and compliance with purity standards. Accurate measurements and documentation are essential.

What is the purpose of mechanical purity?

The purpose of mechanical purity is to ensure that mechanical components perform reliably, reduce the risk of failure, and maintain safety standards in manufacturing and production processes.

What information must be reported on mechanical purity?

Information that must be reported includes component specifications, test results, compliance with purity standards, and any identified contaminants or impurities.

Fill out your mechanical purity online with pdfFiller!

pdfFiller is an end-to-end solution for managing, creating, and editing documents and forms in the cloud. Save time and hassle by preparing your tax forms online.

Mechanical Purity is not the form you're looking for?Search for another form here.

Relevant keywords

Related Forms

If you believe that this page should be taken down, please follow our DMCA take down process

here

.

This form may include fields for payment information. Data entered in these fields is not covered by PCI DSS compliance.