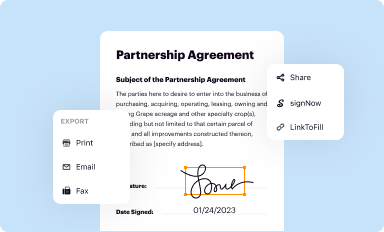

Get the free EMI Injection Molding Supplies Catalog. Injection Molding Supplies Catalog - End of ...

Show details

Solutions For Your EndofBarrel Needs When it comes to developing the technology and equipment necessary to produce injection molded parts with new materials, EMI has the experience and expertise you

We are not affiliated with any brand or entity on this form

Get, Create, Make and Sign emi injection molding supplies

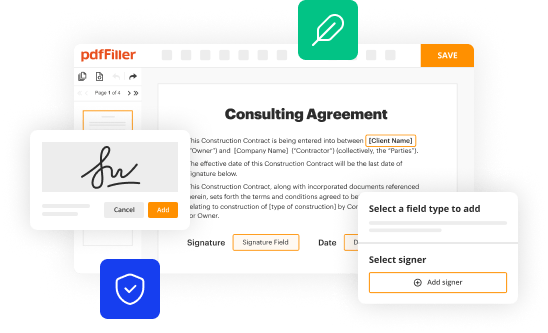

Edit your emi injection molding supplies form online

Type text, complete fillable fields, insert images, highlight or blackout data for discretion, add comments, and more.

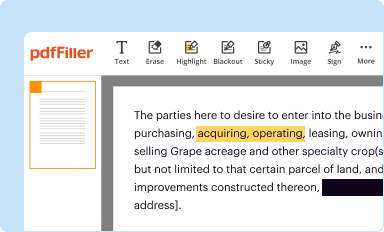

Add your legally-binding signature

Draw or type your signature, upload a signature image, or capture it with your digital camera.

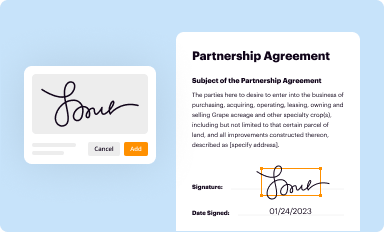

Share your form instantly

Email, fax, or share your emi injection molding supplies form via URL. You can also download, print, or export forms to your preferred cloud storage service.

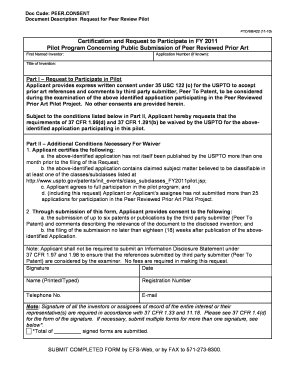

Editing emi injection molding supplies online

To use our professional PDF editor, follow these steps:

1

Create an account. Begin by choosing Start Free Trial and, if you are a new user, establish a profile.

2

Upload a document. Select Add New on your Dashboard and transfer a file into the system in one of the following ways: by uploading it from your device or importing from the cloud, web, or internal mail. Then, click Start editing.

3

Edit emi injection molding supplies. Rearrange and rotate pages, add new and changed texts, add new objects, and use other useful tools. When you're done, click Done. You can use the Documents tab to merge, split, lock, or unlock your files.

4

Get your file. Select the name of your file in the docs list and choose your preferred exporting method. You can download it as a PDF, save it in another format, send it by email, or transfer it to the cloud.

With pdfFiller, it's always easy to work with documents.

Uncompromising security for your PDF editing and eSignature needs

Your private information is safe with pdfFiller. We employ end-to-end encryption, secure cloud storage, and advanced access control to protect your documents and maintain regulatory compliance.

How to fill out emi injection molding supplies

How to fill out emi injection molding supplies

01

Gather all the necessary emi injection molding supplies such as appropriate molds, injection molding machine, raw materials, and safety equipment.

02

Prepare the injection molding machine by ensuring it is in proper working condition and that all settings are adjusted correctly.

03

Prepare the mold by cleaning and inspecting it for any damages or defects.

04

Set up the mold on the injection molding machine, ensuring it is securely in place.

05

Load the raw materials into the machine's feeding system, following the recommended guidelines and proportions.

06

Start the injection molding process by activating the machine and allowing it to heat up to the required temperature.

07

Adjust the machine settings for injection pressure, injection speed, and cooling time according to the specific requirements of the mold and material.

08

Inject the molten material into the mold cavity through the machine's nozzle and runner system.

09

Allow the material to solidify and cool down inside the mold to form the desired shape.

10

Once the cooling time is complete, open the mold and remove the finished product.

11

Inspect the product for any defects or imperfections and make necessary adjustments to the molding process if needed.

12

Repeat the process for additional production cycles, making sure to clean and maintain the machine and mold regularly to ensure optimal performance.

Who needs emi injection molding supplies?

01

Emi injection molding supplies are needed by manufacturers or businesses involved in plastic product manufacturing.

02

Any company or individual planning to produce plastic products through injection molding processes will require these supplies.

03

Common industries that may need emi injection molding supplies include automotive, electronics, medical, packaging, and consumer goods.

04

These supplies are essential for creating high-quality and precision plastic components or products efficiently and effectively.

Fill

form

: Try Risk Free

For pdfFiller’s FAQs

Below is a list of the most common customer questions. If you can’t find an answer to your question, please don’t hesitate to reach out to us.

How can I edit emi injection molding supplies from Google Drive?

pdfFiller and Google Docs can be used together to make your documents easier to work with and to make fillable forms right in your Google Drive. The integration will let you make, change, and sign documents, like emi injection molding supplies, without leaving Google Drive. Add pdfFiller's features to Google Drive, and you'll be able to do more with your paperwork on any internet-connected device.

How do I edit emi injection molding supplies online?

With pdfFiller, the editing process is straightforward. Open your emi injection molding supplies in the editor, which is highly intuitive and easy to use. There, you’ll be able to blackout, redact, type, and erase text, add images, draw arrows and lines, place sticky notes and text boxes, and much more.

How do I fill out the emi injection molding supplies form on my smartphone?

On your mobile device, use the pdfFiller mobile app to complete and sign emi injection molding supplies. Visit our website (https://edit-pdf-ios-android.pdffiller.com/) to discover more about our mobile applications, the features you'll have access to, and how to get started.

What is emi injection molding supplies?

EMI injection molding supplies are materials and components used in the process of injection molding to create electromagnetic interference shielding protection.

Who is required to file emi injection molding supplies?

Manufacturers and suppliers of electronic devices or products that require EMI shielding are required to file EMI injection molding supplies.

How to fill out emi injection molding supplies?

EMI injection molding supplies can be filled out by providing detailed information about the materials used, the quantities supplied, and the intended applications.

What is the purpose of emi injection molding supplies?

The purpose of EMI injection molding supplies is to ensure that electronic devices or products meet regulatory requirements for electromagnetic compatibility and shielding.

What information must be reported on emi injection molding supplies?

The information that must be reported on EMI injection molding supplies includes the type of materials used, the manufacturing processes involved, and the specifications for EMI shielding performance.

Fill out your emi injection molding supplies online with pdfFiller!

pdfFiller is an end-to-end solution for managing, creating, and editing documents and forms in the cloud. Save time and hassle by preparing your tax forms online.

Emi Injection Molding Supplies is not the form you're looking for?Search for another form here.

Relevant keywords

Related Forms

If you believe that this page should be taken down, please follow our DMCA take down process

here

.

This form may include fields for payment information. Data entered in these fields is not covered by PCI DSS compliance.