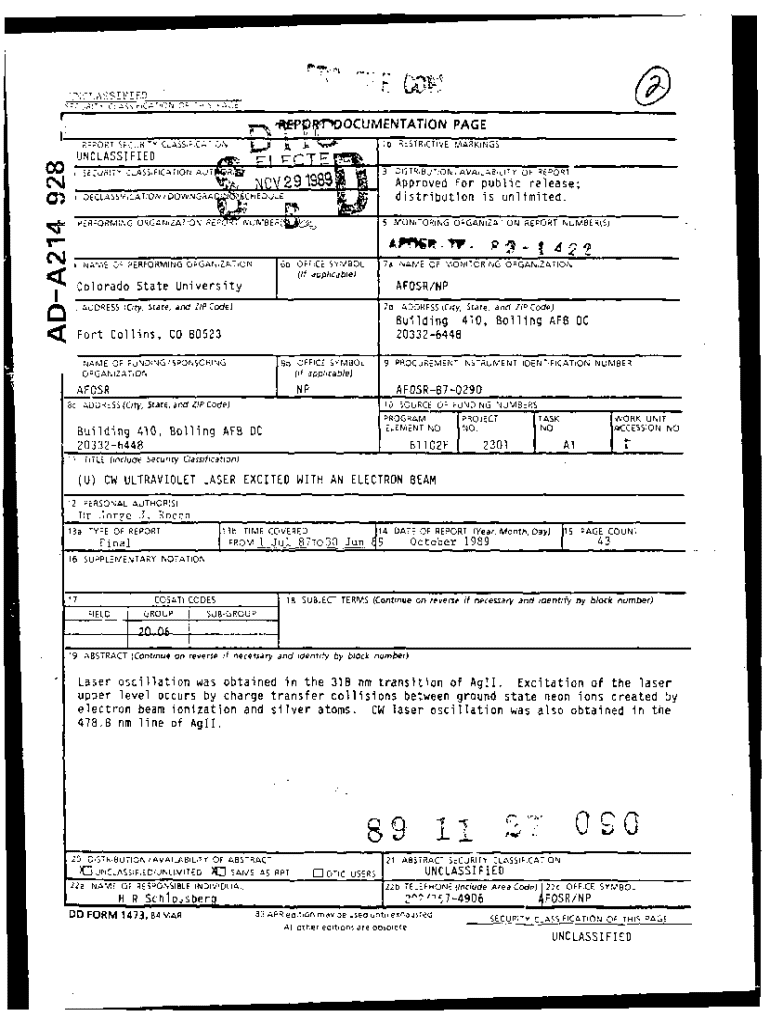

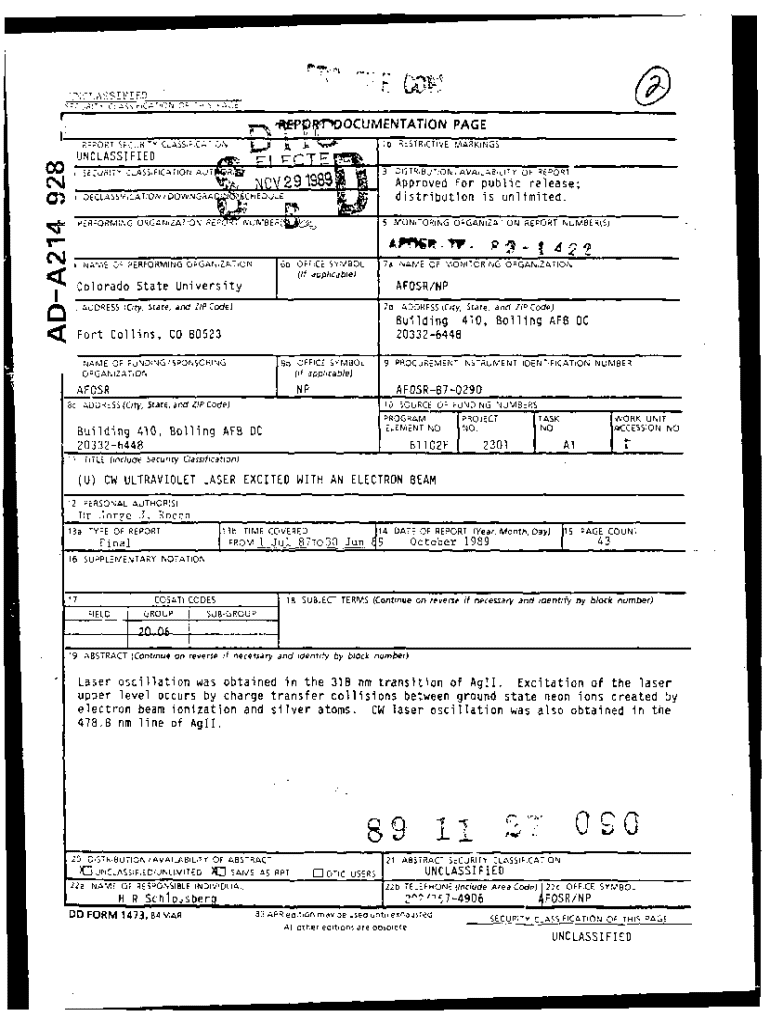

Get the free Cw Ultraviolet Laser Excited With an Electron Beam

Get, Create, Make and Sign cw ultraviolet laser excited

How to edit cw ultraviolet laser excited online

Uncompromising security for your PDF editing and eSignature needs

How to fill out cw ultraviolet laser excited

How to fill out cw ultraviolet laser excited

Who needs cw ultraviolet laser excited?

Understanding CW ultraviolet laser excited form

Understanding CW ultraviolet lasers

Continuous Wave (CW) ultraviolet lasers have emerged as pivotal tools in various applications, fundamentally altering manufacturing, research, and medical procedures. These lasers maintain a steady, uninterrupted light output, differentiating them from pulsed lasers that emit light in short bursts.

Key characteristics include their specific wavelength range, typically between 200 nm and 400 nm, which is crucial for applications that require precise interactions with materials. The stability and coherence inherent in CW lasers enable them to produce high-quality beams, making them indispensable in delicate tasks like micro-machining and fine engraving.

Principles of ultraviolet laser excitation

Understanding the mechanism of laser excitation is pivotal for harnessing the full potential of CW ultraviolet lasers. The process commences with the absorption of energy by electrons in a medium, leading to elevated energy levels. Upon returning to their ground state, these electrons release energy in the form of photons, producing laser light.

The significance of ultraviolet wavelengths cannot be underestimated. They provide short-range energy delivery, effectively interacting with various materials for applications like etching and sterilization. The shorter wavelengths correlate with higher energy, enhancing effectiveness in targeted procedures versus longer wavelengths.

Applications of CW ultraviolet lasers

The versatility of CW ultraviolet lasers extends across various industries. In industrial settings, these lasers are widely used for marking and engraving materials, as their precision reduces waste and enhances product quality. Surface treatments, such as ablation or cleaning, also benefit significantly from the controlled energy delivery of CW lasers.

Scientific research utilizes these lasers for spectroscopy and photochemical reactions, enabling researchers to study molecular interactions at a minuscule scale. Moreover, they have found applications in the medical field, particularly in dermatological treatments that require precise skin adjustments without causing damage to surrounding tissues.

How to select a CW ultraviolet laser

Selecting the right CW ultraviolet laser is crucial for achieving optimal results in your specific application. Key factors include desired wavelength and output power, which significantly impact the effectiveness of the laser for particular tasks. Understanding the requirements of your application and any limitations is essential.

Different models offer various balances of power and energy efficiency. Some lasers are designed for high-power operations, while others prioritize energy savings. Assessing the suitability of each model based on your needs will ensure that you invest in a system that meets both immediate and future demands.

Operating a CW ultraviolet laser

Operating a CW ultraviolet laser necessitates essential safety precautions. Eye safety is paramount due to the dangers posed by ultraviolet light. Protective eyewear must be worn at all times to prevent damage to the eyes. Additionally, ensuring workspace safety, such as limiting access to untrained personnel and using appropriate barriers, reduces risks during operation.

Employing best practices aids in maximizing efficiency and extending the lifespan of the equipment. Using alignment tools for optimal positioning will result in effective energy delivery while regular maintenance and cleaning procedures help uphold laser performance by reducing potential obstructions that could lead to inefficiencies.

CW ultraviolet laser systems overview

A functioning CW ultraviolet laser system consists of several key components that must work in harmony for optimal performance. The laser head is responsible for generating the laser beam, while the power supply provides the necessary energy input. Effective cooling systems are crucial to prevent overheating, which can hamper performance and longevity.

Optics are another critical component, impacting beam quality and focus. Integrating CW ultraviolet lasers with other technologies, including software for operation, enhances the overall functionality and flexibility of applications, allowing users to adapt the system for various tasks efficiently.

Cost considerations in CW ultraviolet laser systems

Understanding the cost structure of CW ultraviolet laser systems is vital for making informed purchasing decisions. The initial investment can vary significantly depending on the model and features; it's essential to factor in long-term operational costs, which may include maintenance, energy consumption, and software updates.

Several elements influence the cost of CW ultraviolet laser systems, such as brand reputation and the level of service support provided. Customizations or additional features can also drive up prices. Evaluating these factors in relation to your budget and application requirements will enable you to choose a system that offers the best return on investment.

Case studies of CW ultraviolet laser applications

Industries have successfully leveraged CW ultraviolet lasers to enhance operational efficiencies. For instance, a leading automotive manufacturer integrated CW UV laser technology into its production line, significantly improving the quality and speed of part marking. This case highlights how precision and reliability can transform manufacturing processes, leading to lower costs and higher productivity.

Another example includes the use of CW ultraviolet lasers in the pharmaceutical industry for sterilization processes. Employing this technology results in quicker, more effective sterilization, leading to enhanced safety and compliance with health regulations. These success stories illustrate the transformative potential of CW UV lasers across distinct sectors.

Future trends in CW ultraviolet laser technology

The landscape of CW ultraviolet laser technology is poised for innovation. Miniaturization and advancements in portability are leading to lighter, more adaptable systems, which could significantly alter their integration in various sectors. Enhanced precision technologies will emerge, offering users more control over laser output for specialized applications.

Moreover, as industries seek novel solutions, we can expect to see exponential growth in the utilization of CW ultraviolet lasers in new fields. Quantum computing and photonic technology are anticipated to benefit immensely from this laser technology, making it critical to keep abreast of these trends for strategic planning and investment.

Interactive tools and resources

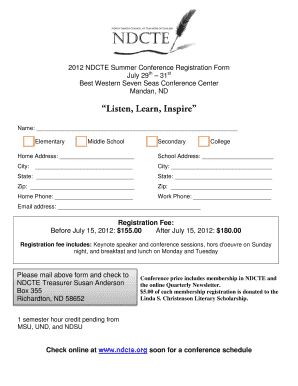

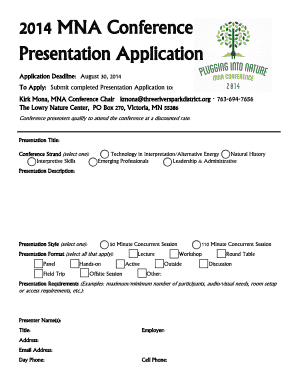

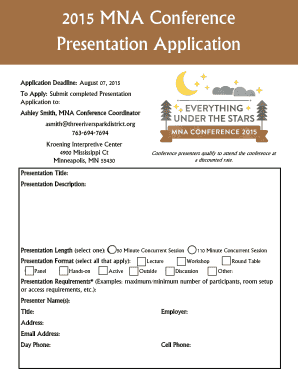

To facilitate the effective use of CW ultraviolet lasers, myriad interactive tools and resources are available. Document templates for laser machine setup can streamline maintenance scheduling and operational checks, allowing for seamless management of the laser systems. It’s crucial to keep organized records to ensure consistent performance and safety compliance.

Community engagement plays a vital role in advancing knowledge. Forums dedicated to sharing experiences, addressing troubleshooting, and exchanging best practices foster collaboration among users. Participating in workshops and webinars focused on advanced applications of CW ultraviolet lasers can keep users informed about evolving technologies and methods.

For pdfFiller’s FAQs

Below is a list of the most common customer questions. If you can’t find an answer to your question, please don’t hesitate to reach out to us.

How do I fill out the cw ultraviolet laser excited form on my smartphone?

Can I edit cw ultraviolet laser excited on an Android device?

How do I fill out cw ultraviolet laser excited on an Android device?

What is cw ultraviolet laser excited?

Who is required to file cw ultraviolet laser excited?

How to fill out cw ultraviolet laser excited?

What is the purpose of cw ultraviolet laser excited?

What information must be reported on cw ultraviolet laser excited?

pdfFiller is an end-to-end solution for managing, creating, and editing documents and forms in the cloud. Save time and hassle by preparing your tax forms online.