Get the free Min/max Temperature Log for Refrigerator and Freezer

Get, Create, Make and Sign minmax temperature log for

Editing minmax temperature log for online

Uncompromising security for your PDF editing and eSignature needs

How to fill out minmax temperature log for

How to fill out minmax temperature log for

Who needs minmax temperature log for?

Minmax temperature log for form: A comprehensive guide

Understanding minmax temperature logging

Minmax temperature logging refers to the process of tracking the minimum and maximum temperatures of a certain environment over a specified period. This method is crucial for maintaining optimal conditions, particularly in industries like food service and pharmaceuticals. Accurate minmax temperature logs help ensure that products are stored within safe temperature ranges, thereby preventing spoilage and ensuring consumer safety.

In the food industry, for instance, meat and dairy products have to be kept at specific temperatures to avoid bacterial growth. Similarly, pharmaceutical products must remain within strict temperature controls to preserve their efficacy. The importance of this logging process can’t be overstated, as it forms a vital part of compliance with health regulations and guidelines.

Key features of minmax temperature logging tools

When selecting a minmax temperature logger, certain features are non-negotiable. A robust logger must include a digital display showing real-time readings, and good data storage capabilities to keep historical data for compliance audits. Connectivity options, such as USB and Bluetooth, are essential for easy data transfer and remote monitoring.

Different types of minmax temperature loggers serve varied purposes. For example, data logging refrigerator/freezer thermometers are designed to function efficiently at low temperatures. In contrast, ultra-low and high-accuracy thermometers suit specialized applications. Dual and infrared thermometers offer quick and contactless readings, providing flexibility across multiple settings.

Choosing the right minmax temperature logger

Choosing the right temperature logger depends on various factors. The temperature range and accuracy are paramount; for instance, food applications generally require a broader range than pharmaceutical ones. Additionally, consider the data recording frequency and capacity, as more frequent logging provides more detailed insights into temperature fluctuations.

When comparing models, look for detailed user feedback and performance ratings. This information can provide insights into the reliability and durability of different loggers. Be sure to also evaluate customer support and available warranties as part of your decision-making process.

Setting up your minmax temperature logger

Setting up your minmax temperature logger does not need to be complicated. Begin by unboxing and performing initial checks like ensuring that the device is undamaged and properly calibrated. Calibration should be done as per the manufacturer's guidelines to guarantee accuracy.

Next, configure the recording parameters such as the logging interval. Setting alerts for high and low temperatures is crucial for proactive monitoring. Real-time notifications ensure that any temperature excursions can be rectified in a timely manner, safeguarding the integrity of stored goods.

Data logging and management techniques

Implementing best practices for data logging can significantly influence operational efficiency. Regular checks and maintenance of your logger will ensure it operates optimally. The frequency of data collection is also essential; logs should be collected at intervals that accurately reflect the environmental changes without overwhelming the user with excessive data.

Data analysis also plays a crucial role. Visualizing temperature trends using graphs or software aids in identifying anomalies that may indicate equipment failure. Understanding these patterns can inform preventative measures and improve overall temperature management strategies.

Filling out and managing your temperature log form

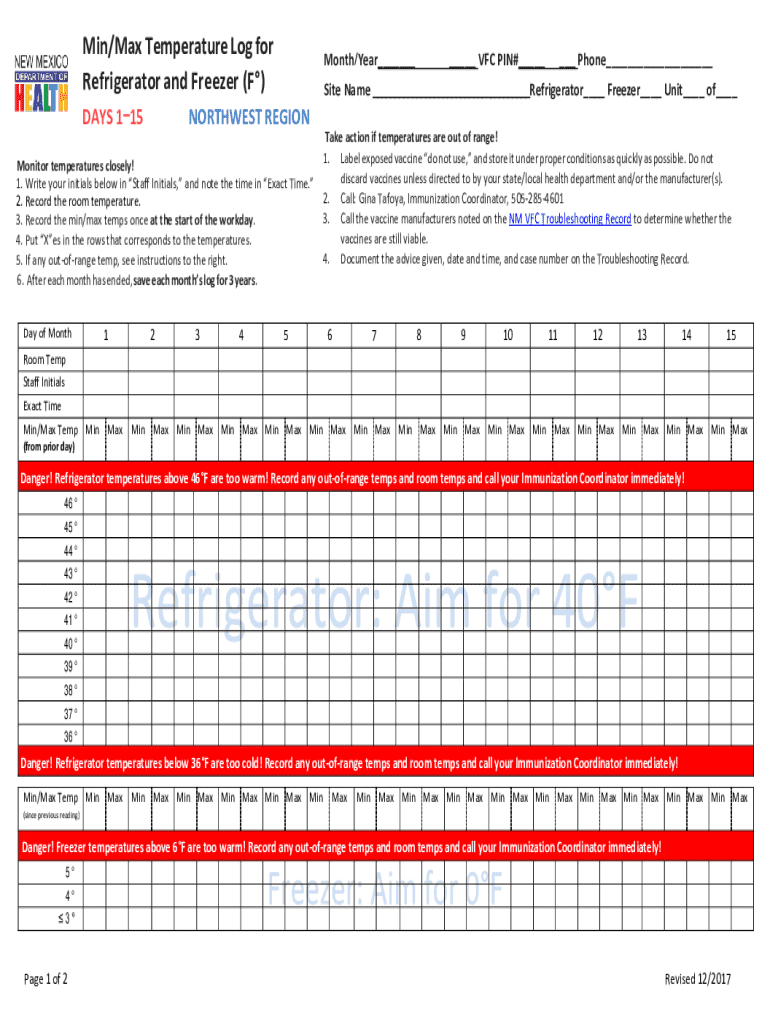

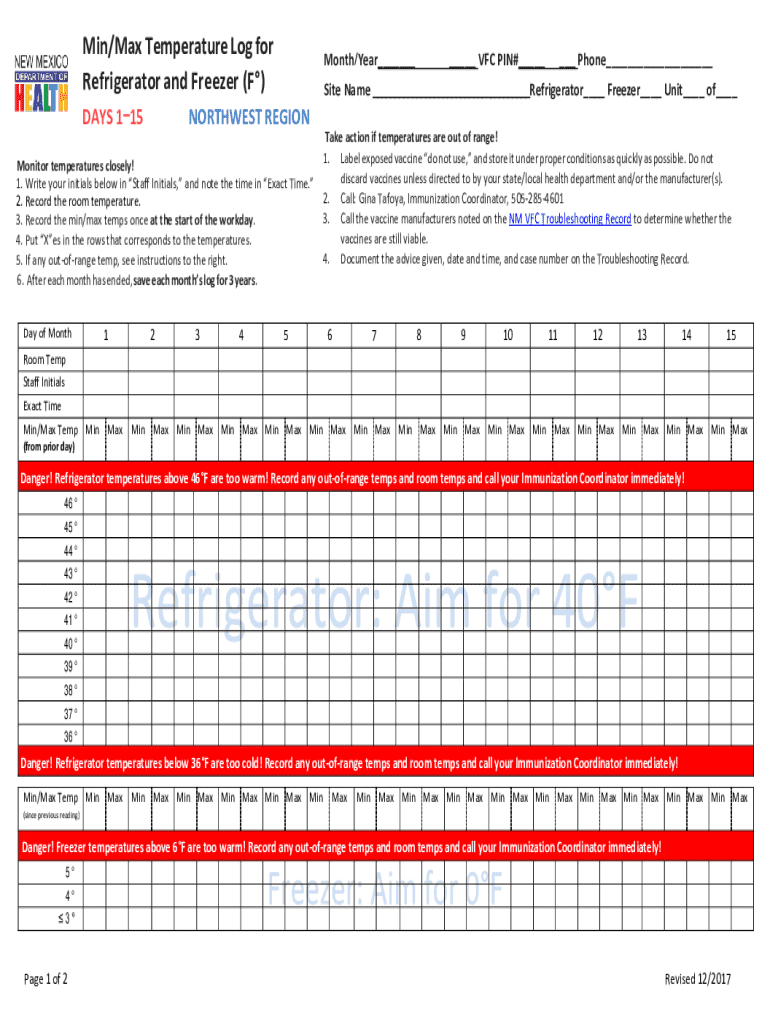

Temperature log forms are essential for documenting temperature readings in a structured and standardized manner. Different industries may implement various forms; however, they generally include similar key fields such as date, time, minimum and maximum temperatures, and initials of the person taking the readings.

To complete the form, be meticulous in noting the temperatures, ensuring to sign and date appropriately. Using tools like pdfFiller can offer benefits in managing and editing these logs to ensure accuracy and compliance. Properly filled-out forms facilitate audits and foster accountability.

Troubleshooting common issues

In temperature logging, problems can arise that hinder efficient monitoring. Issues like sensor malfunctions or connectivity problems are among the most common. Identifying these problems quickly can minimize disruptions and maintain compliance.

Users often have questions regarding these devices. It’s beneficial to consult troubleshooting guides or customer service options provided by manufacturers for effective solutions. Regularly checking connectivity and sensor stability can help in averting many of these issues.

Regulatory compliance and standards

Various industries operate under stringent guidelines set by regulatory bodies such as the FDA, CDC, and WHO. Adhering to these standards ensures the integrity of products and protects public health. Accurate temperature logging serves as proof of compliance, which is essential during audits and inspections.

Documentation of temperature logs must be meticulous and thorough. Many organizations employ standardized forms to maintain consistency across records. This approach makes it easier to produce necessary documents for regulatory compliance, demonstrating a commitment to maintaining product safety.

Interactive tools and resources

Utilizing interactive features can enhance the efficiency of filling out and managing your temperature log forms, especially with tools like pdfFiller. Digital document management simplifies the process of filling, signing, and editing. Interactive templates can be customized to match specific industry needs, ensuring a tailored approach to data logging.

Accessing pre-designed templates through pdfFiller can save time and ensure compliance with the necessary documentation standards. These tools make it easier to adapt your documentation processes to meet changing regulations and internal needs, improving overall data management efficiency.

Final thoughts on effective temperature management

Effective temperature management significantly impacts operational efficiency across industries. Regularly monitoring minmax temperature logs not only ensures compliance but also contributes to improved product lifecycles and customer satisfaction. Encouraging best practices in temperature management creates a culture of accountability and vigilance.

By integrating advanced tools like pdfFiller, users can streamline their forms and improve their operational workflows. Ultimately, staying ahead in temperature management serves to protect both the business’s interests and consumer safety, solidifying trust in the integrity of the products offered.

For pdfFiller’s FAQs

Below is a list of the most common customer questions. If you can’t find an answer to your question, please don’t hesitate to reach out to us.

How do I execute minmax temperature log for online?

Can I create an electronic signature for signing my minmax temperature log for in Gmail?

How do I fill out the minmax temperature log for form on my smartphone?

What is minmax temperature log for?

Who is required to file minmax temperature log for?

How to fill out minmax temperature log for?

What is the purpose of minmax temperature log for?

What information must be reported on minmax temperature log for?

pdfFiller is an end-to-end solution for managing, creating, and editing documents and forms in the cloud. Save time and hassle by preparing your tax forms online.