Get the free Min/max Temperature Log for Refrigerator and Freezer (f°)

Get, Create, Make and Sign minmax temperature log for

How to edit minmax temperature log for online

Uncompromising security for your PDF editing and eSignature needs

How to fill out minmax temperature log for

How to fill out minmax temperature log for

Who needs minmax temperature log for?

Minmax temperature log for form: A comprehensive guide for effective temperature monitoring

Understanding minmax temperature logging

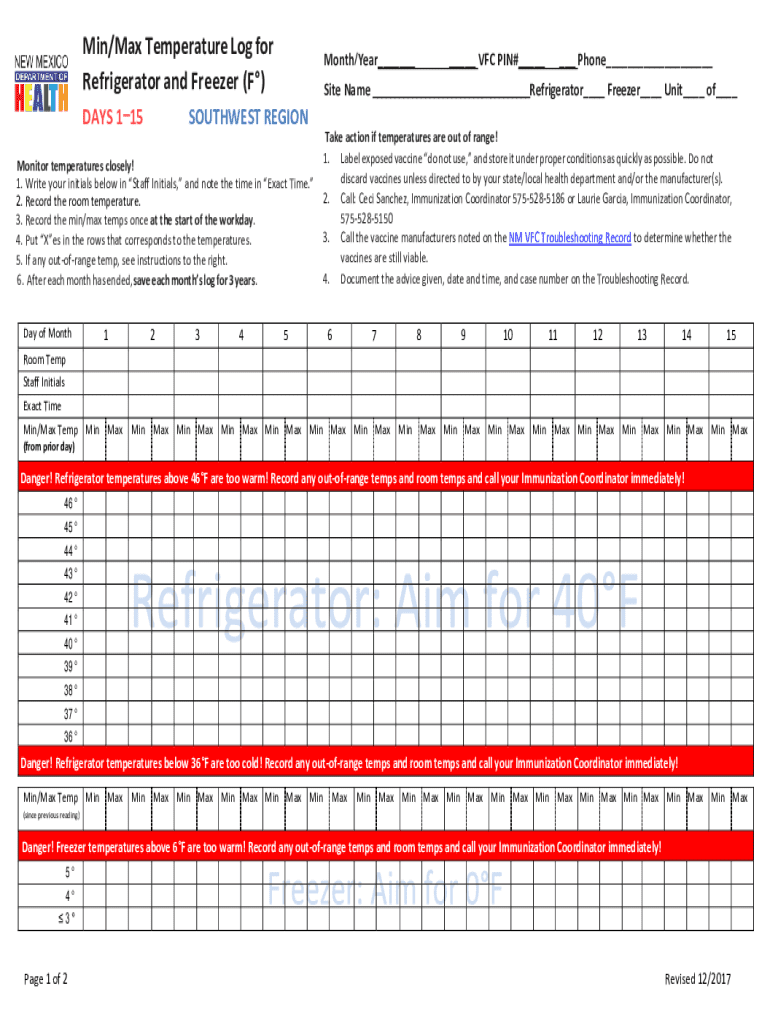

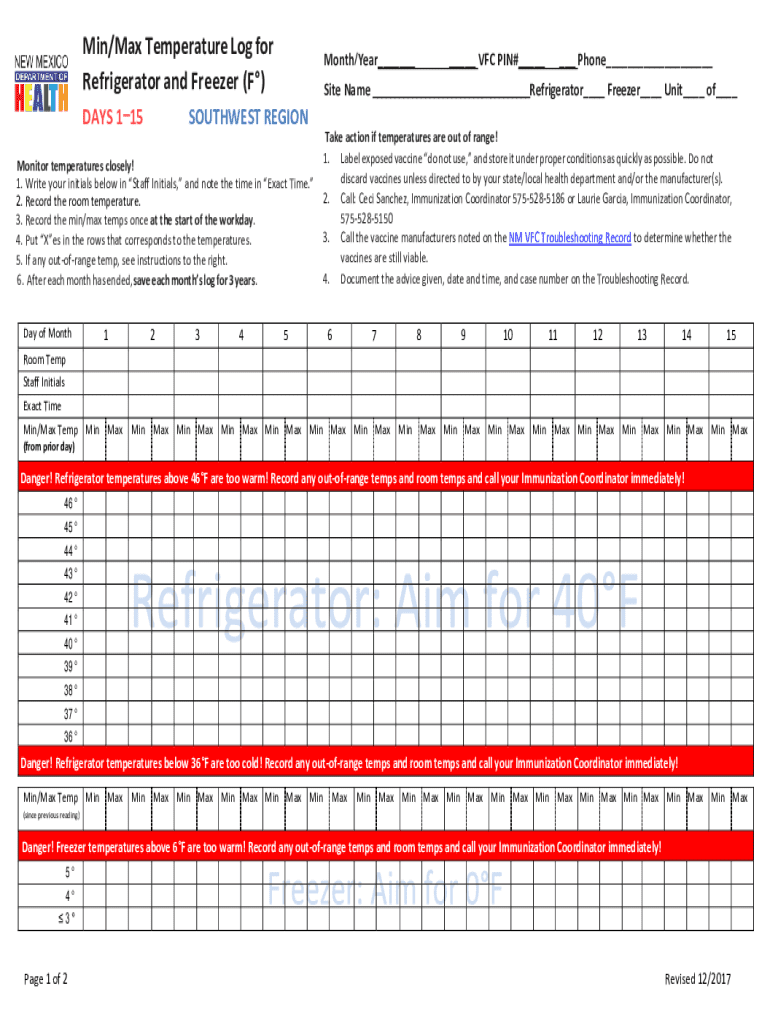

MinMax temperature logging is a systematic approach to recording the minimum and maximum temperature readings over a specified period. This method ensures that critical temperature thresholds are maintained, particularly in environments where temperature fluctuations could lead to adverse effects, such as spoilage, loss of efficacy, or experimental variances. By clearly delineating these temperature ranges, businesses and organizations can uphold safety standards and ensure compliance across various sectors.

The significance of temperature logs transcends mere record-keeping; they play a crucial role in industries like healthcare, food safety, and research. For instance, in healthcare facilities, proper minmax temperature logs are vital for the storage of vaccines, ensuring they remain effective and safe for public use. In the food industry, temperature logging is essential for managing inventory and safeguarding consumer health. Research contexts also rely on accurate temperature records to ensure consistency and reliability in experimental outcomes.

Features of an effective minmax temperature log

An effective minmax temperature log must have several key features to ensure reliability and usefulness. First and foremost, the ability to record both minimum and maximum temperatures is necessary for monitoring critical ranges. Manual logs may suffice in some cases; however, automatic logs offer significant advantages, such as real-time data capture and alerts when temperatures exceed preset thresholds. Automated logging can reduce human error and ensure more consistent monitoring.

Historical data tracking is another important feature. The ability to reference past temperature data is essential for compliance with industry regulations, helping organizations demonstrate adherence to safety standards. Moreover, tracking historical data enables users to identify trends and recognize patterns in temperature changes over time, aiding in proactive decision-making.

Choosing the right temperature logging tool

Choosing between manual logs and digital solutions is crucial and depends on various factors unique to your needs. Manual logs may be more cost-effective for small operations; however, they lack the efficiencies that digital solutions provide. Digital temperature logging tools offer enhanced accuracy, the ability to record data instantly, and improved data management through features such as cloud storage and mobile access.

When selecting a logging tool, consider key features such as accuracy and calibration, user interface ease, and data exporting capabilities. For example, being able to export records in formats like CSV or PDF can simplify reporting and sharing data with stakeholders. Additionally, cloud storage ensures access from anywhere, making it convenient for commitment to a fully integrated document management system.

Best practices for using minmax temperature logs

To ensure effective minmax temperature logging, it’s essential to adopt best practices. Regularly updating temperature logs should be a priority; conducting updates on a daily or weekly schedule can prevent lapses in data integrity. Consistency in logging is key, as inaccuracies can lead to compliance issues and jeopardize safety standards.

Additionally, providing comprehensive training for staff on proper temperature logging processes is critical. Training sessions should cover the operational protocols for using the logging tool effectively. By developing clear operational protocols, organizations can create a reliable foundation for temperature management practices and minimize the risk of errors.

Interactive tools for effective temperature monitoring

Organizations looking for robust options should explore various software solutions tailored for temperature logging. These platforms often have integrated features that directly address the unique needs of temperature management. They'll help ensure thorough documentation and ready retrieval of temperature data while complementing existing operational systems.

Moreover, mobile applications have emerged as valuable tools for on-the-go updates and monitoring. They allow users to log temperatures conveniently and receive immediate alerts in case of fluctuations. Essential features to look for in mobile apps include user-friendliness, synchronization with digital logs, and real-time notifications for any critical temperature breaches, ensuring effective temperature management at all times.

Troubleshooting common issues with temperature logs

Discrepancies in temperature readings can be problematic, leading to failures in compliance or safety breaches. Understanding the potential causes of inaccurate readings can help organizations implement appropriate rectification steps. Factors such as device malfunction, improper calibration, or environmental influences may contribute to discrepancies. Regular maintenance and calibration checks are critical in alleviating these issues.

In instances of data loss, organizations should have robust prevention strategies in place, including regular backups and cloud storage solutions. Understanding recovery options is also essential; many modern logging solutions offer backup options and data retrieval capabilities if the unexpected occurs. This ensures ongoing access to historical logs and continuity in operations.

Industry-specific applications and case studies

Different sectors have unique requirements for temperature logging. For instance, in the healthcare industry, maintaining stringent temperature controls for vaccine management is paramount. Vaccines require specific temperatures to retain their effectiveness, making accurate logging essential. Case studies have shown that facilities utilizing automated temperature logs experienced fewer incidents of lost efficacy, highlighting the importance of effective logging.

Similarly, in the food sector, temperature logging for restaurant supply chains plays a vital role in food safety. Timely temperature documentation ensures that food products remain safe for consumption. Case examples illustrate that businesses practicing diligent temperature monitoring have effectively prevented spoilage and met compliance standards, creating a safer dining environment for customers.

Integrating minmax temperature logs with other document management processes

Integration capabilities of temperature logs with broader document management systems provide robust benefits. Utilizing platforms like pdfFiller for creating PDF solutions enhances log management by allowing teams to collaborate effortlessly and share logs with simplicity. Cloud-based accessibility allows stakeholders to view logs from anywhere, supporting effective teamwork and ensuring everyone is informed of temperature statuses.

Additionally, streamlining document signing and sharing processes offers another layer of efficiency. By implementing e-signatures for log approvals, organizations can accelerate the compliance process, making it easier to share with relevant authorities or partners. This approach minimizes delays in documentation, promoting responsiveness in operations while reinforcing adherence to safety regulations.

Future trends in temperature logging

Technological advancements are continually shaping the landscape of temperature logging. Innovations in sensor technology now offer greater accuracy and responsiveness, making temperature monitoring systems more reliable than ever. In particular, the integration of artificial intelligence and machine learning algorithms is streamlining data analysis. These technologies can analyze trends, predict potential temperature excursions, and automate alerts for rapid responses.

As regulatory landscapes evolve, organizations must remain vigilant about anticipated changes that could impact temperature logging practices. Staying ahead of these shifts will require adaptability and assurance that your logging systems comply with the latest standards. By preparing for changes in legislation, such as stricter quality controls, organizations can maintain competitive edges and uphold customer trust.

For pdfFiller’s FAQs

Below is a list of the most common customer questions. If you can’t find an answer to your question, please don’t hesitate to reach out to us.

How do I modify my minmax temperature log for in Gmail?

How do I make changes in minmax temperature log for?

How do I complete minmax temperature log for on an Android device?

What is minmax temperature log for?

Who is required to file minmax temperature log for?

How to fill out minmax temperature log for?

What is the purpose of minmax temperature log for?

What information must be reported on minmax temperature log for?

pdfFiller is an end-to-end solution for managing, creating, and editing documents and forms in the cloud. Save time and hassle by preparing your tax forms online.