Get the free Centrifugal Boiler Blowdown Separators

Get, Create, Make and Sign centrifugal boiler blowdown separators

How to edit centrifugal boiler blowdown separators online

Uncompromising security for your PDF editing and eSignature needs

How to fill out centrifugal boiler blowdown separators

How to fill out centrifugal boiler blowdown separators

Who needs centrifugal boiler blowdown separators?

Understanding Centrifugal Boiler Blowdown Separators Form

1. Understanding centrifugal boiler blowdown separators

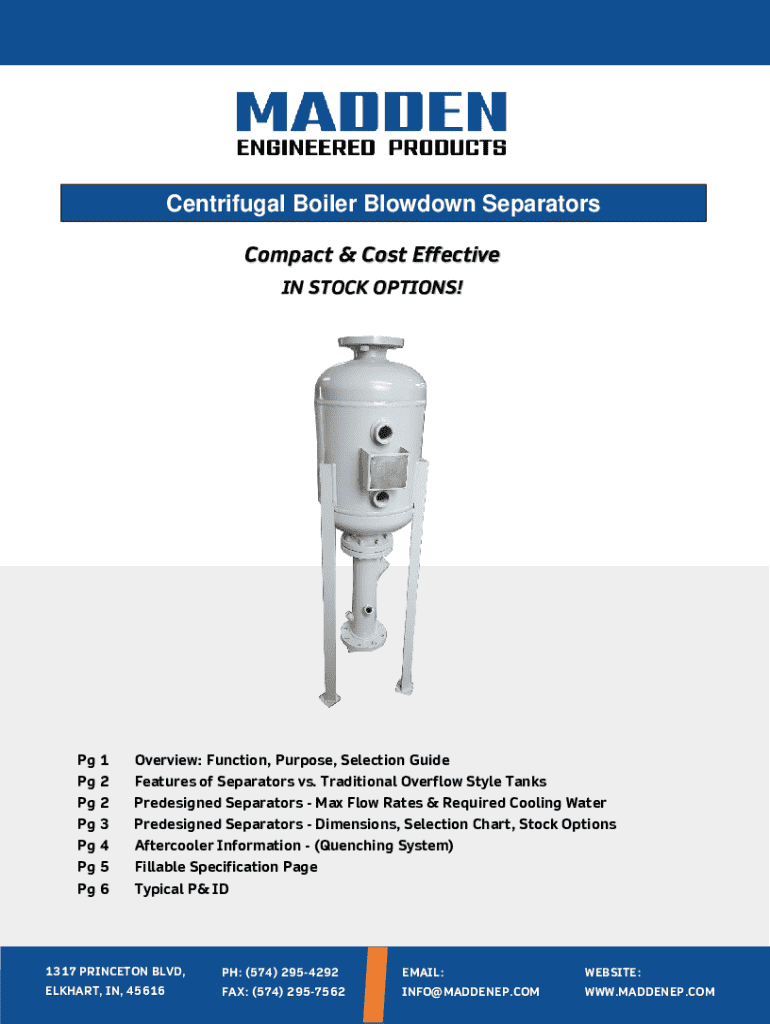

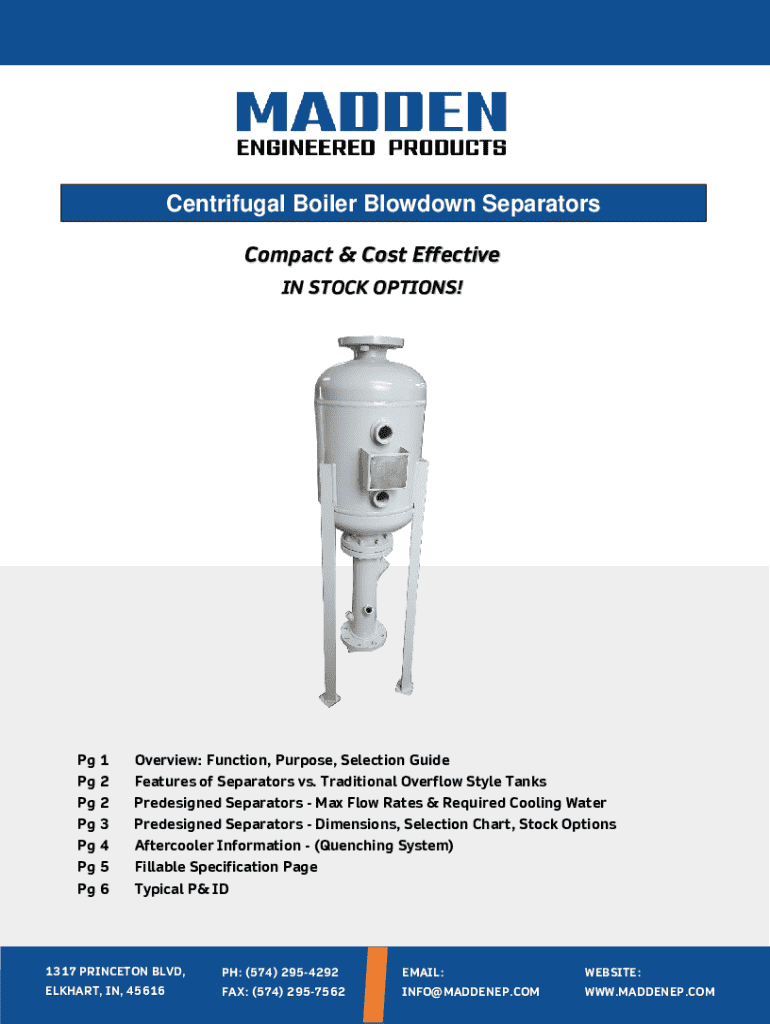

Centrifugal boiler blowdown separators play a critical role in the operation of industrial and commercial boilers. Their primary function is to separate contaminants from the boiler water, allowing for efficient maintenance and improved operational safety. By managing the blowdown process effectively, these separators help maintain optimal water quality, enhance boiler efficiency, and contribute to cost savings.

These separators utilize centrifugal force, which accelerates the separation of solids from liquids, resulting in cleaner water being discharged from the boiler. This process not only protects the boiler components from damage due to contamination but also ensures compliance with environmental regulations regarding wastewater treatment.

2. Advantages of using blowdown separators

The adoption of centrifugal boiler blowdown separators provides several advantages that can significantly enhance boiler operations. First and foremost, these systems drastically increase efficiency by minimizing the quantity of contaminated water released during blowdown operations. This efficiency translates directly into operational savings and reduces the need for additional water treatment processes.

Moreover, by effectively separating contaminants, blowdown separators improve the overall water quality in the boiler system. Clean water can lead to less scaling and corrosion within the boiler, prolonging the lifespan of the equipment and reducing maintenance costs. Additionally, utilizing blowdown separators can lead to enhanced environmental compliance, as they mitigate the potential for harmful constituents entering wastewater systems.

3. Detailed overview of the blowdown process

To understand the effective operation of centrifugal boiler blowdown separators, it’s essential to grasp the blowdown process itself. Blowdown refers to the periodic removal of water from a boiler to control the concentration of impurities. During the blowdown operation, water is expelled from the system, typically through a specialized valve designed for this purpose.

The frequency and timing of blowdown operations can significantly impact the efficiency of the boiler system. Regular monitoring and adjustments are needed to ensure that the blowdown process removes enough contaminants while minimizing water loss. Proper best practices include scheduling blowdown when the system is under a low load, ensuring safety and efficiency.

4. Types of centrifugal separators

When considering centrifugal blowdown separators, it's important to note the various types available. These can be broadly categorized into vertical and horizontal separators, which differ in orientation and processing efficiency.

Moreover, blowdown separators can be classified into continuous and batch types. Continuous separators provide uninterrupted operation, while batch separators are suitable for processes requiring less constant handling of wastewater. Understanding the differences between centrifugal and other types of separators, like gravity separators, is essential for making informed choices about equipment that best suits specific boiler operations.

5. Applications of centrifugal boiler blowdown separators

Centrifugal boiler blowdown separators find applicability across various sectors. In industrial settings, they are commonly used in manufacturing processes where steam generation is critical. These separators ensure that the water quality remains high, enabling efficient steam production.

In commercial heating systems, such as restaurants and hotels, maintaining boiler efficiency through effective blowdown operations becomes paramount to reduce operational costs. Even in residential heating solutions, well-calibrated separators can help homeowners achieve significant savings and efficiency improvements. Numerous case studies highlight successful implementations in diverse environments, demonstrating the broad utility of these systems.

6. Design considerations for centrifugal separators

Design considerations for centrifugal boiler blowdown separators are critical to ensuring optimal performance. Various factors come into play, including the intended application, expected load, and environmental conditions. The design must accommodate fluctuations in flow rates and pressures to maintain efficiency.

Material selection for the construction of blowdown separators is also paramount. Materials must withstand the corrosive nature of boiler water and potentially high temperatures. Proper size and capacity planning are essential to ensure that the separator can effectively handle the expected blowdown rates while remaining compact for space-constrained installations.

7. Monitoring and maintenance

Regular monitoring and maintenance of centrifugal boiler blowdown separators are vital to ensure continued operation efficiency. Establishing a maintenance schedule encompassing routine checks, filter replacements, and part assessments can preempt costly breakdowns and repairs.

Troubleshooting common issues should involve assessing the performance metrics against expected outcomes; discrepancies may indicate wear, blockages, or system miscalculations. Implementing effective tools and techniques for monitoring can include pressure gauges, flow meters, and more advanced diagnostic software to ensure optimal efficiency.

8. Filling out the blowdown separator form

Completing the centrifugal boiler blowdown separators form accurately is essential for obtaining the correct equipment and ensuring adherence to your specific requirements. Begin with the personal information section; clarity here allows for smooth communication with suppliers and service providers. Next, fill in the boiler specifications, detailing operational parameters that could influence separator performance.

It’s also important to specify separator preferences based on your operational needs. Additionally, a section dedicated to maintenance history can provide insights into prior issues or requirements, ensuring your new separator is compatible with existing systems. Accuracy in this form can lead to significant benefits, from proper equipment recommendations to enhanced future maintenance.

9. Collaborative features of pdfFiller

Utilizing pdfFiller for managing your centrifugal boiler blowdown separators form can streamline the process significantly. This platform enables you to edit PDF documents seamlessly, ensuring all fields are filled correctly per your specifications. eSigning and sharing documents from anywhere with your team promotes collaboration and efficiency.

Furthermore, pdfFiller provides a comprehensive cloud-based solution for managing documents, offering features to track changes and store files securely. This correlation between accurate documentation and operational efficiency can lead to significant improvements in productivity and compliance.

10. Frequently asked questions (FAQs)

Understanding common queries regarding centrifugal boiler blowdown separators can aid both new and experienced users in maximizing efficiency. For instance, many users wonder about the role of a blowdown separator in a boiler system. Essentially, these separators are designed to remove impurities, thus enhancing the quality of the water circulating within the boiler.

Another frequent question relates to maintenance requirements. Regular checks should be made to ensure that the separator operates within optimal parameters; any anomalies warrant investigation. Automation of the blowdown process is also a popular topic, as advancements in technology enable greater precision in managing these systems.

11. User success stories

Real-life applications of centrifugal boiler blowdown separators show transformative results across various industries. Many companies report substantial cost savings and increased operational efficiency after implementing these systems. The strategic use of pdfFiller for document management complements the adoption of efficient machinery, making it easier to handle form submissions and track maintenance records.

Sharing these success stories highlights the potential of integrating advanced technologies into boiler systems and their documentation practices, ultimately paving the way for smoother operations and enhanced compliance.

12. Contact & support information

For inquiries related to centrifugal boiler blowdown separators or assistance with pdfFiller, customer support is available to guide users through any challenges they may encounter. The importance of having access to knowledgeable support cannot be overstated, as operational efficiency often hinges on quick problem resolution and expert advice.

Resources for further assistance include user manuals, FAQs, and direct communication channels, ensuring that all users can achieve successful outcomes in their operations.

For pdfFiller’s FAQs

Below is a list of the most common customer questions. If you can’t find an answer to your question, please don’t hesitate to reach out to us.

How do I edit centrifugal boiler blowdown separators online?

How can I edit centrifugal boiler blowdown separators on a smartphone?

How do I fill out centrifugal boiler blowdown separators using my mobile device?

What is centrifugal boiler blowdown separators?

Who is required to file centrifugal boiler blowdown separators?

How to fill out centrifugal boiler blowdown separators?

What is the purpose of centrifugal boiler blowdown separators?

What information must be reported on centrifugal boiler blowdown separators?

pdfFiller is an end-to-end solution for managing, creating, and editing documents and forms in the cloud. Save time and hassle by preparing your tax forms online.