Get the free Control and Isolation Valve Process Data Sheets

Get, Create, Make and Sign control and isolation valve

Editing control and isolation valve online

Uncompromising security for your PDF editing and eSignature needs

How to fill out control and isolation valve

How to fill out control and isolation valve

Who needs control and isolation valve?

Control and Isolation Valve Form: A Comprehensive Guide

Understanding control and isolation valves

Control valves and isolation valves are integral components in various industrial processes. While they serve different functions, their combined operation is vital for controlling and directing fluid flow effectively within a system. Control valves adjust the flow rate of fluids based on predetermined conditions, while isolation valves ensure the complete shut-off of fluid flow in pipelines or systems.

The distinct characteristics of these valve types must be understood to harness their true potential in an engineering context. Control valves can modulate flow and pressure dynamically, which influences overall system efficiency. In contrast, isolation valves are crucial for maintenance and emergency situations, providing safety by halting flow completely.

Applications of control and isolation valves

Control and isolation valves find applications in multiple industries, each with unique specifications based on the operational requirements. Industries such as oil and gas rely heavily on these valves to maintain stable operations under extreme conditions. Similarly, water treatment facilities utilize these valves for both regulation and isolation purposes to ensure safe and efficient processing.

In chemical manufacturing, precise control over reactions is necessary for product quality and safety. The valves enable operators to fine-tune flow rates and isolate sections of equipment during maintenance. Their roles in ensuring safe operation, regulatory compliance, and optimally functioning systems cannot be overstated.

Types of control and isolation valves

Various types of control and isolation valves are available, each serving specific functionality and applications within the industrial spectrum. Understanding these types aids in selecting the appropriate valve for the task at hand.

Gate valves are commonly used for isolation due to their ability to provide a straight-through flow path, whereas globe valves are preferred for flow regulation due to their greater ability to control flow rates. Ball valves are well-suited for on/off applications and are often used in isolation because they offer a tight seal. Butterfly valves, with their compact design, tend to be used in larger pipes where space is at a premium.

Critical components of control and isolation valves

The performance and efficiency of control and isolation valves heavily rely on their various components. The valve body plays a significant role in determining the valve's ability to withstand pressure and temperature changes. Design consideration for the body's material and configuration must align with the intended application.

Actuating mechanisms, such as electric, pneumatic, and hydraulic systems, enable valves to respond dynamically to control signals. The selection of these systems dramatically influences the responsiveness and operational efficiency. Additionally, sealing mechanisms directly impact the valve's ability to prevent leaks and maintain integrity under varying conditions.

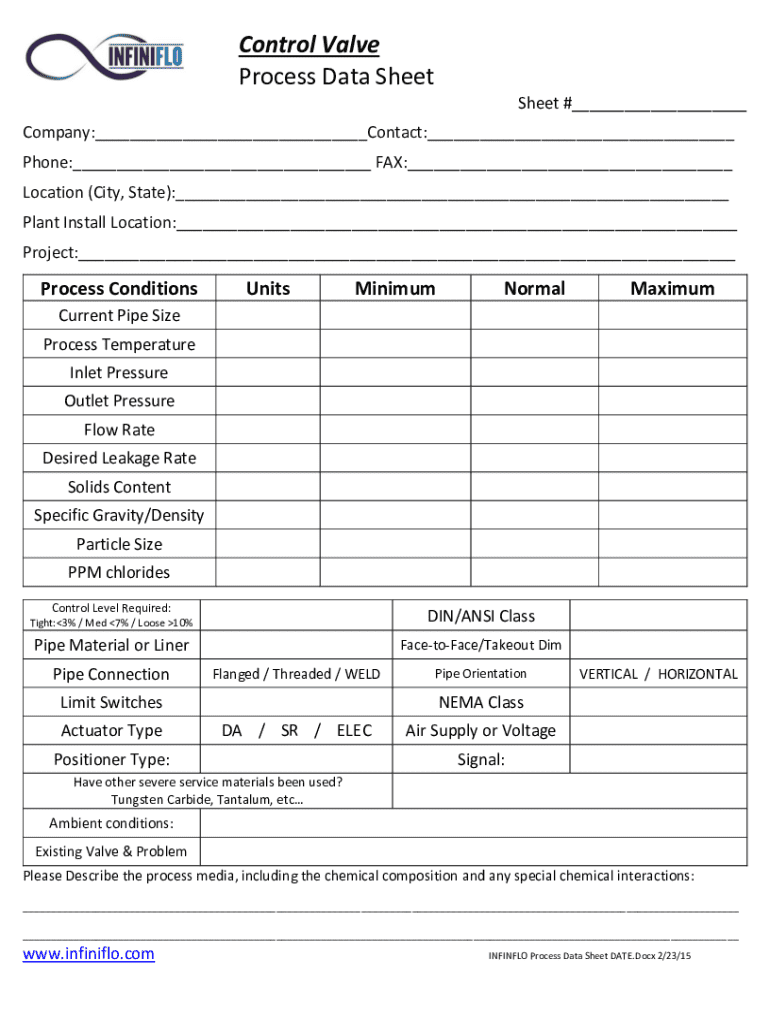

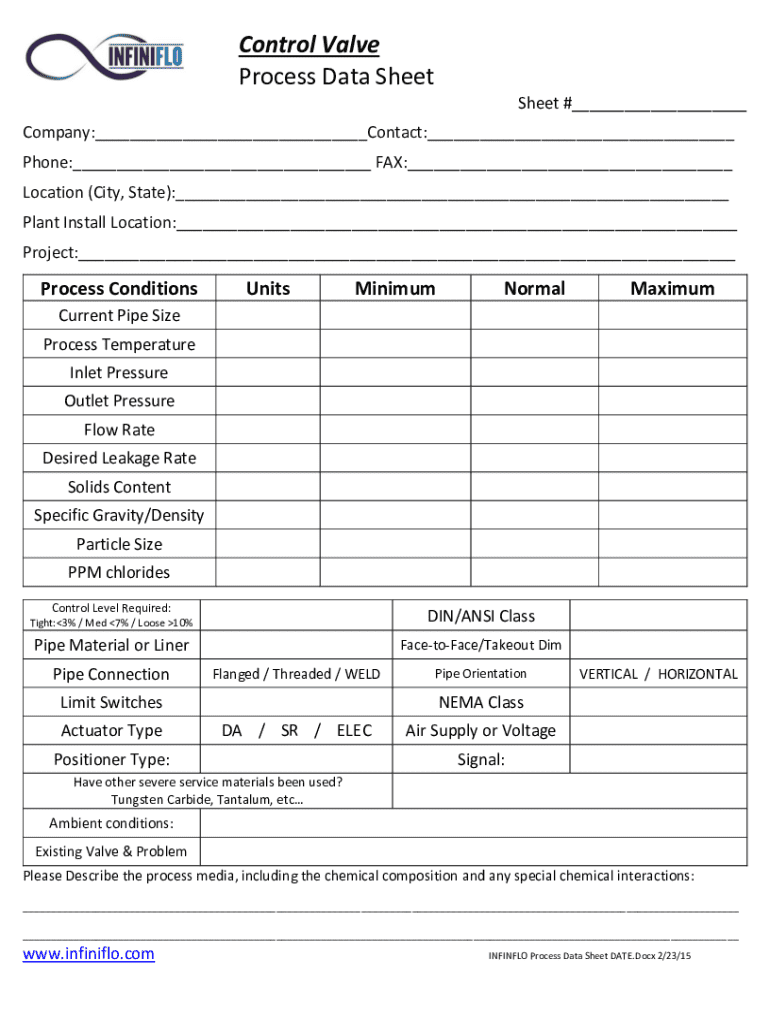

Filling out the control and isolation valve form

Completing the control and isolation valve form accurately is crucial for ensuring that the right specifications are met for your application. Start by collecting basic information such as the project name and installation site, which sets the foundation for further details.

Next, carefully select the valve type and specifications based on your operational needs. Documenting the installation site’s specifics, such as accessibility and environmental conditions, is equally important. Lastly, provide detailed operational conditions to ensure the selected valve performs optimally.

Managing documents related to control and isolation valves

Efficient document management is paramount in the engineering domain, especially when dealing with control and isolation valves. Utilizing tools like pdfFiller can streamline the document creation, modification, and management processes. The platform enables users to edit, eSign, and collaborate effectively, ensuring all stakeholders have access to the same information.

Features such as cloud storage allow users to access documents remotely, enhancing team collaboration across various locations. As engineers or project managers work on valve projects, leveraging collaboration tools gives teams the ability to communicate efficiently and handle document revisions effortlessly.

Best practices for control and isolation valve usage

Implementing best practices during procurement, installation, and maintenance of control and isolation valves is essential for extending their life and optimizing system performance. Regular maintenance and inspection are vital. Scheduling periodic checks ensures valves operate efficiently and helps in early detection of potential issues.

Safety considerations must always be a priority when working with valves. Ensuring that proper protocols are followed during installation and operation can prevent accidents and equipment failure. Moreover, upgrading and retrofitting valves as technology advances ensures the system maintains up-to-date operational capabilities.

Case studies and real-world examples

Learning from real-world applications of control and isolation valves provides insight into best practices and common challenges faced across industries. For instance, in a chemical manufacturing facility, the integration of smart control valve technologies significantly improved process efficiency and reduced wastage.

Another example can be seen in the water treatment sector, where the implementation of isolation valves allowed for efficient maintenance without disrupting service. Such examples showcase the importance of proper valve management and highlight the lessons learned during project execution.

Frequently asked questions (FAQs)

Addressing common inquiries about control and isolation valves is essential for clarifying misconceptions and guiding users in their selection and management of these crucial components. For instance, the main difference between control and isolation valves lies in their functionality; control valves adjust flow, while isolation valves stop flow completely.

Determining the right size of a valve for a specific application involves understanding the flow requirements and operating conditions. Automation of control and isolation valves is also possible, enhancing operational efficiency. Routine maintenance is necessary to ensure valves function correctly and securely.

Conclusion on control and isolation valve applications

Control and isolation valves form a foundational aspect of fluid management in various industrial settings. Understanding their functions and applications ensures efficiency and safety in numerous processes. The strategic use of pdfFiller further enhances document management regarding valve specifications and operations, ensuring teams remain organized and capable of addressing dynamic challenges.

Looking ahead, advancements in valve technology, including the integration of smart systems and automation, are paving the way for improved operational efficiencies. As industries continue to evolve, the need for precise and reliable valve mechanisms will remain paramount.

For pdfFiller’s FAQs

Below is a list of the most common customer questions. If you can’t find an answer to your question, please don’t hesitate to reach out to us.

How can I get control and isolation valve?

Can I sign the control and isolation valve electronically in Chrome?

Can I create an eSignature for the control and isolation valve in Gmail?

What is control and isolation valve?

Who is required to file control and isolation valve?

How to fill out control and isolation valve?

What is the purpose of control and isolation valve?

What information must be reported on control and isolation valve?

pdfFiller is an end-to-end solution for managing, creating, and editing documents and forms in the cloud. Save time and hassle by preparing your tax forms online.