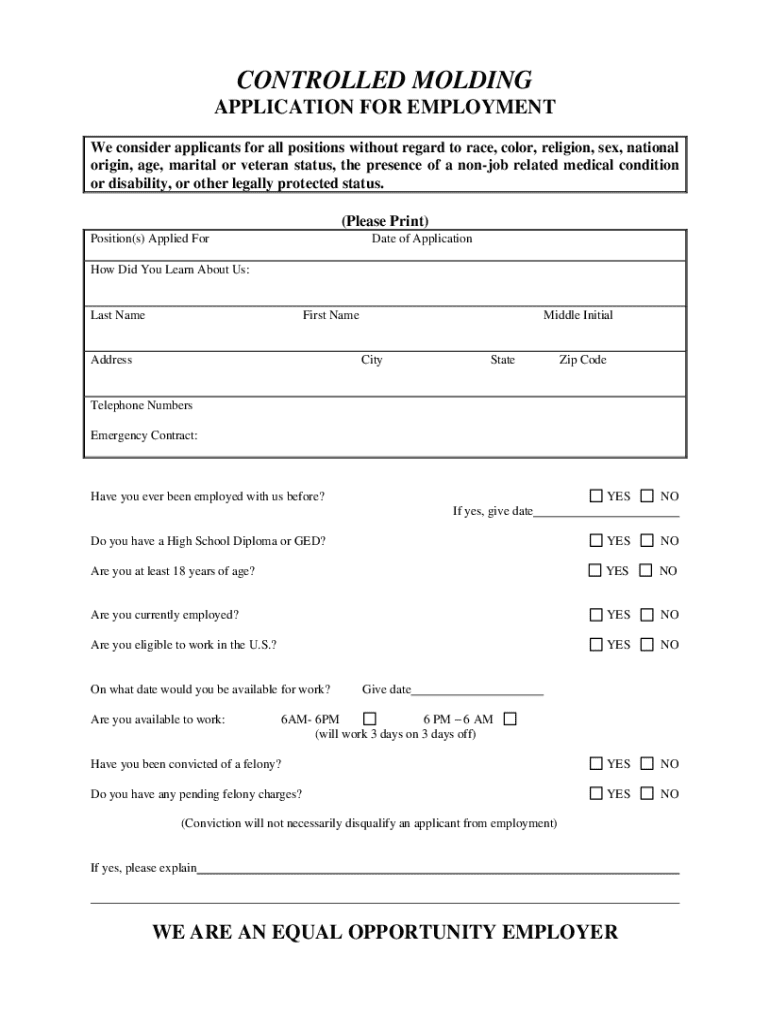

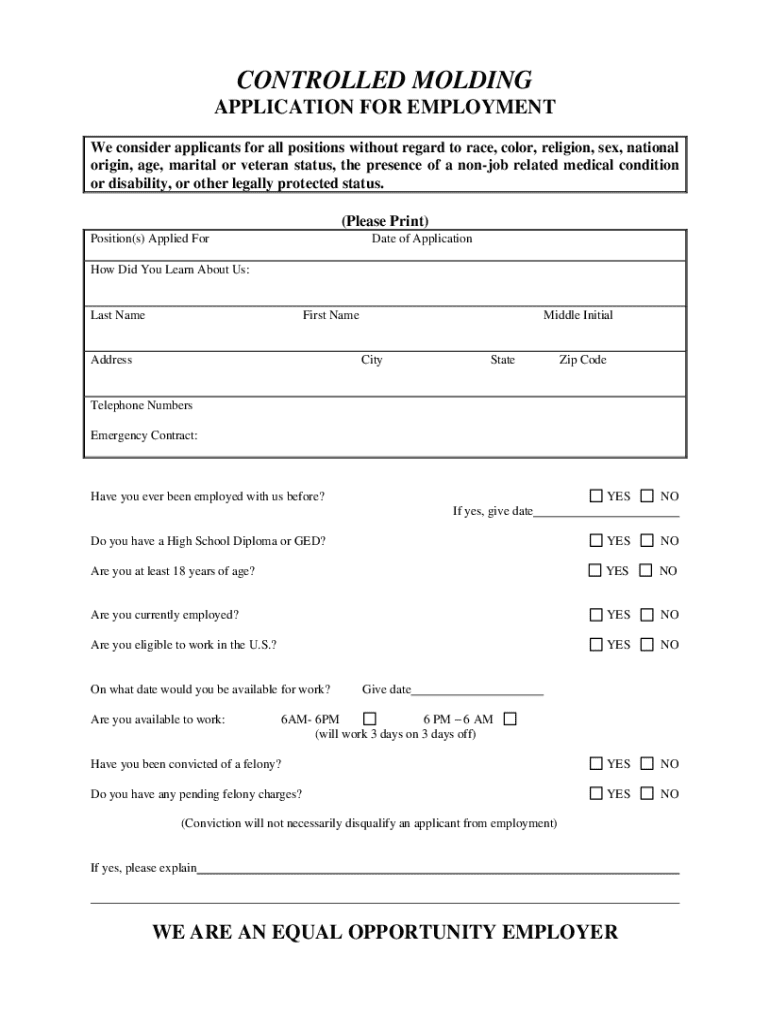

Get the free Controlled Molding Application for Employment

Get, Create, Make and Sign controlled molding application for

Editing controlled molding application for online

Uncompromising security for your PDF editing and eSignature needs

How to fill out controlled molding application for

How to fill out controlled molding application for

Who needs controlled molding application for?

Controlled molding application for form: A comprehensive how-to guide

Understanding controlled molding in form creation

Controlled molding refers to techniques used in the formation of materials where precision and consistency are essential. It plays a crucial role in creating standardized forms, which are vital in document creation and management. This process ensures that every form produced maintains identical measurements, shapes, and properties, thus reducing errors and enhancing the overall quality of the documentation.

Key terms associated with controlled molding include molding parameters, material selection, and process optimization. Each of these elements contributes to the effectiveness of the controlled molding application, highlighting its multifaceted importance in crafting forms that are not only functional but also reliable.

The evolution of molding techniques

Molding techniques have historical roots that date back thousands of years, evolving from simple manual molding to advanced technologies. Early examples include casting in clay and metal. The industrial revolution marked a significant turning point, as mechanization led to greater efficiency and consistency in molding processes.

In recent years, controlled molding processes have seen significant advancements, notably through automation and precision engineering. Automation in molding employs software-controlled machinery to enhance accuracy, remove the human error factor, and improve production rates. Precision engineering, on the other hand, allows for intricate designs and complex geometries to be easily replicated in mass production.

Types of molding techniques

There are various molding methods employed depending on the desired material and application. The most common types include plastic molding, rubber molding, and silicone molding. Each technique has unique attributes that make it suitable for specific use cases.

Understanding these techniques allows teams to select the appropriate molding process for their specific document management needs, ensuring better outcomes and increased efficiency.

Applications of controlled molding in document management

Controlled molding has considerable applications in document creation, significantly improving accuracy and consistency. By employing structured molding techniques, organizations can optimize resource allocation, ensuring that every document is crafted with precision without unnecessary rework or mistakes.

For instance, consider a case study in the legal sector where controlled molding is applied to standardize legal forms. By utilizing precise molding methods, law firms can create templates that ensure compliance with regulations, reducing the risk of errors that could lead to costly disputes.

The role of technology in controlled molding applications

Technology plays a pivotal role in enhancing the efficiency of controlled molding applications. Software tools designed for molding efficiency, such as document and PDF editing platforms, allow teams to streamline document creation processes. For instance, integrating tools like pdfFiller can significantly simplify the process of editing, signing, and managing documents.

Cloud-based solutions further improve collaboration and accessibility, as teams can manage documents from anywhere, facilitating better communication and faster turnaround times.

Step-by-step guide to implementing controlled molding in document creation

Implementing controlled molding in document creation involves several strategic steps to ensure effectiveness. Here’s a step-by-step guide to navigate the process:

Challenges and solutions in controlled molding applications

Despite its advantages, the implementation of controlled molding applications comes with its share of challenges. Common issues include variability in material properties and inadequate workflows in traditional methods, leading to inconsistencies.

Innovative solutions like smart material selection and workflow optimization can mitigate these challenges. Utilizing advanced tools within platforms like pdfFiller can streamline workflows, reduce errors, and enhance the overall effectiveness of document management.

Future trends in controlled molding for forms

As technology continues to advance, molding techniques are expected to evolve significantly. Future trends indicate a growing integration of AI and machine learning in molding processes, enhancing precision and automating routine tasks.

Emerging innovations such as 3D printing are also expected to transform the landscape of controlled molding, allowing for rapid prototyping and the creation of highly complex forms. pdfFiller remains at the forefront, adapting features to accommodate these changes and ensure users can leverage the latest technologies efficiently.

Industry insights: What to consider when adopting controlled molding techniques

When considering the adoption of controlled molding techniques, organizations should focus on best practices for effective implementation. Key considerations include selecting the right molding process, leveraging technology for better collaboration and efficiency, and establishing metrics to measure success.

Interactive tools and resources for mastering controlled molding

To master controlled molding applications, users can benefit from interactive tools that simplify the document creation process. The features offered by pdfFiller enhance user experience by enabling easy editing, signing, and real-time collaboration.

Additionally, frequently asked questions about controlled molding can provide clarity and guidance. User testimonials and success stories demonstrate how pdfFiller transforms document management, showcasing impactful results from real-world applications.

Corporate use cases of controlled molding

Various industries utilize controlled molding techniques to meet their document management needs. Corporations in manufacturing heavily rely on controlled molding for producing forms that require consistency in specification and quality.

From the legal sector, where precise documentation is critical, to healthcare, where forms must meet stringent regulations, the benefits stretch across sectors, making controlled molding a versatile choice for any business aiming for accuracy and efficiency.

Connecting with experts: Insights and knowledge sharing

Engaging with professionals in the molding industry can yield valuable insights. Participants are encouraged to attend workshops, webinars, and networking events focused on controlled molding techniques, as these opportunities provide a platform for sharing knowledge and experiences.

Such initiatives are instrumental in understanding evolving trends and best practices, ensuring that teams continually grow and refine their approach to controlled molding applications.

For pdfFiller’s FAQs

Below is a list of the most common customer questions. If you can’t find an answer to your question, please don’t hesitate to reach out to us.

How can I modify controlled molding application for without leaving Google Drive?

How do I edit controlled molding application for in Chrome?

How do I complete controlled molding application for on an Android device?

What is controlled molding application for?

Who is required to file controlled molding application for?

How to fill out controlled molding application for?

What is the purpose of controlled molding application for?

What information must be reported on controlled molding application for?

pdfFiller is an end-to-end solution for managing, creating, and editing documents and forms in the cloud. Save time and hassle by preparing your tax forms online.