Get the free Conditioning System Using Microchannel and Fin- and-Tube ...

Get, Create, Make and Sign conditioning system using microchannel

Editing conditioning system using microchannel online

Uncompromising security for your PDF editing and eSignature needs

How to fill out conditioning system using microchannel

How to fill out conditioning system using microchannel

Who needs conditioning system using microchannel?

Conditioning system using microchannel form

Overview of microchannel cooling systems

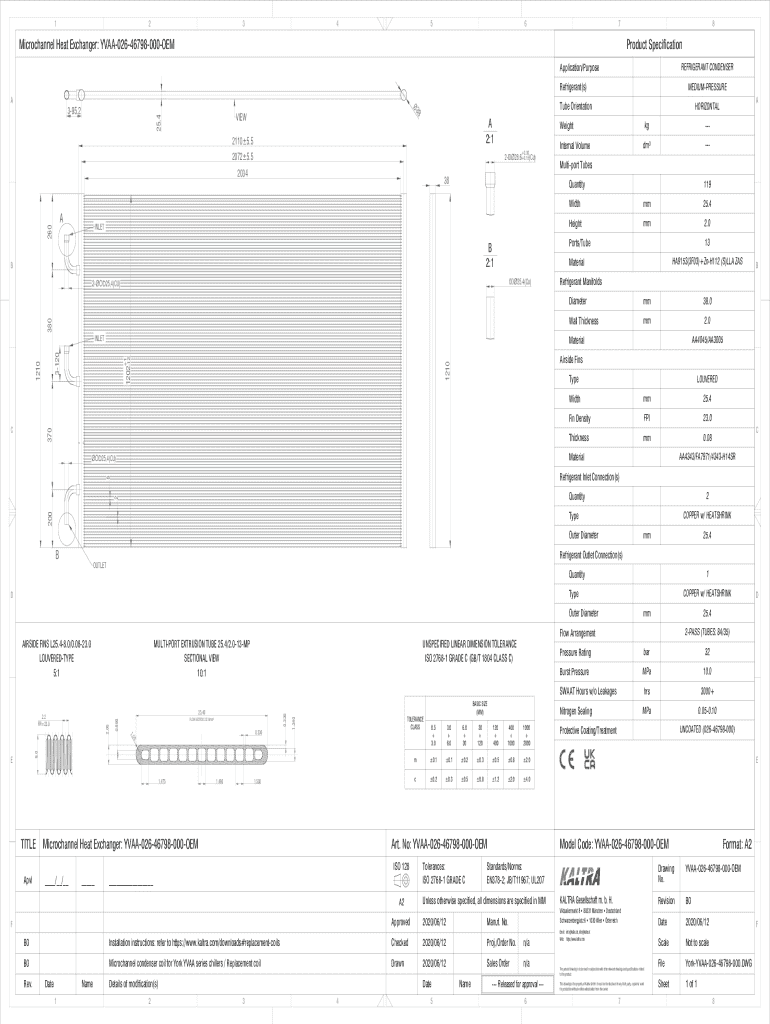

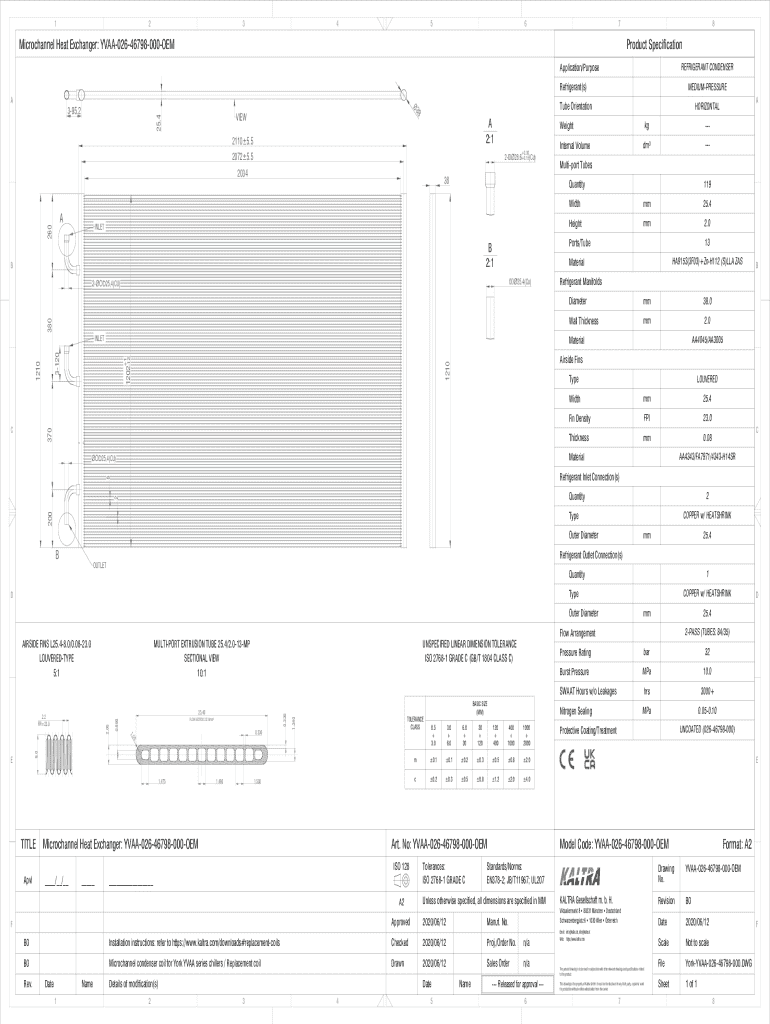

A microchannel cooling system is an innovative approach to air conditioning technology that employs extremely small channels, typically on the order of millimeters, within heat exchangers. These microchannels allow for enhanced heat transfer capabilities, which have become increasingly essential in modern HVAC applications. With a growing emphasis on energy efficiency and sustainability, microchannel technology has gained momentum as a key player in conditioning systems.

Efficiency plays a pivotal role in the effectiveness of air conditioning units, particularly in commercial and industrial environments where energy costs can escalate swiftly. The development of microchannel technology reflects a historical focus on optimizing cooling systems, dating back to its initial adaptations in the early 2000s. This section traces the evolution and adoption of microchannel technology, highlighting its impact on the design of modern cooling solutions.

Advantages of using microchannel forms in conditioning systems

Opting for microchannel forms in conditioning systems comes with a multitude of advantages that enhance both performance and environmental impact. One of the foremost benefits is their compact design, leading to space-saving benefits that are invaluable in environments with limited real estate.

Key components of a microchannel air conditioning system

A microchannel air conditioning system comprises several pivotal components that work in unison to ensure optimal performance. At the heart of the system lies the microchannel heat exchanger, which is characterized by its unique design specifications that facilitate efficient heat exchange. The intricate nature of these channels enhances surface area and thus improves thermal conductivity.

In addition to the heat exchanger, an overview of the refrigeration cycle is essential. The cycle involves compressors, which circulate refrigerant, and expansion devices that regulate pressure and flow, combined with strategically placed fans that optimize airflow. The containment structures also play a crucial role in ensuring system integrity and efficiency.

Designing a microchannel conditioning system

When designing a microchannel conditioning system, several key considerations must be taken into account to ensure optimal functionality. One fundamental aspect is selecting the right microchannel form. While aluminum is often preferred for its lightweight properties, copper may be chosen for its conductivity advantages, with each material having its unique benefits.

Installation guidelines for microchannel systems

Successful installation of microchannel systems begins with thorough pre-installation checks to ensure all components are ready and suitable for the specific application. Once confirmed, a step-by-step installation process is critical to guaranteeing performance efficiency while minimizing errors.

Key steps include gathering necessary tools and materials, adhering strictly to safety precautions, and implementing best practices during installation. Post-installation, conducting system checks ensures that adjustments can be readily made to optimize performance right from the start.

Operational and maintenance practices

Regular maintenance is paramount in sustaining the functionality and efficiency of microchannel systems. Establishing a well-defined maintenance schedule allows for proactive measures to be taken in identifying potential issues before they escalate.

Common troubleshooting methods include recognizing symptoms of performance degradation, cleaning microchannel units to eliminate debris buildup, and considering updates to components for even greater efficiency. By regularly assessing the system’s performance, operators ensure longevity and reliability.

Innovations in microchannel conditioning system technology

The field of microchannel conditioning systems is continually evolving, propelled by innovations that aim to enhance performance and adaptability. Current trends include the integration of smart technologies, enabling better monitoring and control of system performance through IoT connectivity.

Future developments show promise in materials science, offering the potential for even lighter and more efficient designs. Case studies of leading-edge implementations further exemplify how organizations are leveraging this technology to achieve remarkable energy savings and operational improvements.

Utilizing pdfFiller for documentation and management

Managing the documentation associated with microchannel conditioning systems has never been easier with pdfFiller. Users can leverage this platform to create, edit, and manage installation forms, ensuring all necessary documentation is available and well-organized.

Interactive tools and resources

Utilizing various online calculators can significantly enhance the efficacy of system designs and installations. Tools available on platforms like pdfFiller help users assess efficiency, ensuring that every aspect of the microchannel system is configured correctly.

Community engagement and support

Engaging with community forums and groups allows innovators to share experiences and insights related to microchannel systems. Accessing expert guidance through these platforms can aid in overcoming challenges and enhancing knowledge.

Conclusion: The future of air conditioning with microchannel solutions

The microchannel form signifies a major step forward in conditioning system technology, embodying key benefits such as improved efficiency, environmental sustainability, and space-saving designs. As industries increasingly embrace innovation, the future of air conditioning systems appears promising with these advanced technologies at the forefront.

Examining the microchannel approach reaffirms a commitment to optimized cooling solutions that not only satisfy consumer demands but also address broader environmental concerns. Transitioning towards these efficient systems underscores an industry-wide push for sustainable development practices.

Additional documentation and help sections

For those involved in implementing or maintaining microchannel conditioning systems, having swift access to relevant documentation is crucial. Platforms such as pdfFiller offer direct links to related forms and templates that assist in managing operations effectively.

Additionally, the support center provides resources on how to access help when needed, ensuring users can tap into available assistance quickly, fostering a culture of continuous improvement and support.

For pdfFiller’s FAQs

Below is a list of the most common customer questions. If you can’t find an answer to your question, please don’t hesitate to reach out to us.

How do I execute conditioning system using microchannel online?

How do I edit conditioning system using microchannel online?

How do I fill out conditioning system using microchannel using my mobile device?

What is conditioning system using microchannel?

Who is required to file conditioning system using microchannel?

How to fill out conditioning system using microchannel?

What is the purpose of conditioning system using microchannel?

What information must be reported on conditioning system using microchannel?

pdfFiller is an end-to-end solution for managing, creating, and editing documents and forms in the cloud. Save time and hassle by preparing your tax forms online.