Get the free Clad Metal Applications

Get, Create, Make and Sign clad metal applications

Editing clad metal applications online

Uncompromising security for your PDF editing and eSignature needs

How to fill out clad metal applications

How to fill out clad metal applications

Who needs clad metal applications?

Comprehensive Guide to Clad Metal Applications Form

Understanding clad metal

Clad metal, a composite material made by bonding different metals, offers unique properties that enhance performance across various industries. This assembly allows for the combination of materials to achieve specific functionalities that would be difficult to obtain using a single type of metal. In practice, clad metal often features a core material that provides structural integrity, with outer layers that offer desirable characteristics such as corrosion resistance or electrical conductivity.

Historically, clad metal has evolved significantly, gaining traction in sectors such as aerospace and automotive. Its development paralleled advancements in welding technology, allowing manufacturers to exploit the benefits of this versatile approach. Key properties such as improved thermal and electrical conductivity, weight reduction, and enhanced durability have solidified clad metal's place as a crucial component in high-performance applications.

The science behind clad metal

The choice of materials used in clad metal applications is critical to achieving the desired performance characteristics. Common combinations include copper and aluminum, stainless steel with mild steel, and various alloys tailored for specific environments. This selection impacts electrical conductivity, thermal performance, and resistance to adverse environmental conditions.

Cladding techniques vary in complexity and suitability depending on the application. Three popular methods include roll bonding, which involves pressing and rolling together layers under extreme pressure; explosive welding, utilizing controlled explosions to join metals; and laser welding, which melts and fuses the edges using a high-intensity laser beam. Each of these techniques has its own advantages, such as speed, efficiency, and the ability to join dissimilar materials.

Clad metal applications

Clad metals are finding extensive applications across various industries due to their advantageous attributes. The aerospace industry, for example, utilizes clad metals for both structural and aerodynamic components. In automotive manufacturing, these metals are employed to enhance vehicle safety and reduce weight, which contributes to overall fuel efficiency.

In the electronics sector, clad metals are critical for making reliable electrical connections. Additionally, the construction industry benefits from their use in corrosion-resistant building materials. Some specific applications include: electrical connectors and contacts, often made with copper-clad steel to optimize conductivity; thermal management solutions, which utilize specialized designs to dissipate heat effectively; and high-temperature components typically found in high-performance machinery.

Selecting the right clad metal form

When it comes to selecting the appropriate clad metal form for a project, several key factors must be considered. The application requirements are paramount; understanding the environment in which the clad metal will function is essential to making the right choice. Factors such as heat, chemical exposure, and mechanical stress will dictate the ideal metal combinations.

Cost considerations inevitably play a role as well. It is essential to balance budget constraints against the long-term benefits offered by clad metals. Additionally, the material availability can influence decisions, as not all manufacturers can provide every possible clad metal combination. Tools such as form selection tools and comparative analysis charts can substantially aid in determining the best fit for particular needs.

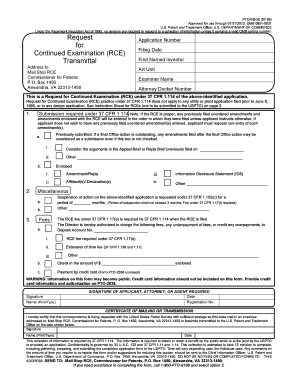

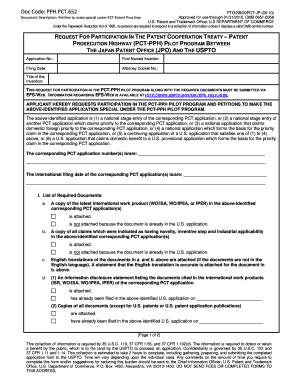

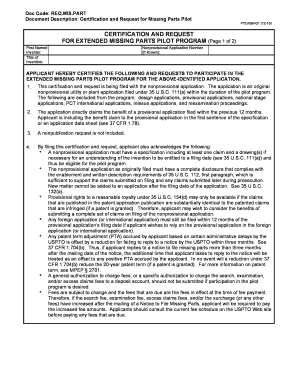

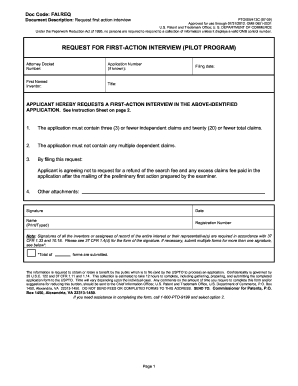

Filling out the clad metal applications form

Filling out a clad metal applications form requires organization and clarity. Begin by gathering all necessary information, including specific application details, technical specifications, and project deadlines. It's crucial to break down each section into manageable parts and provide accurate data to avoid any miscommunication or delays in processing.

Common mistakes to avoid include leaving sections incomplete, using vague descriptions, and failing to double-check accuracy before submission. Utilizing pdfFiller's cloud-based platform can greatly simplify this process, allowing for easy edits and reviews before finalizing the document.

Editing and managing your clad metal applications form

Once the clad metal applications form is filled out, utilizing pdfFiller's cloud-based editing tools can enhance the efficiency of managing the document. Features for collaboration allow teams to work together seamlessly, making real-time updates and providing feedback directly on the document.

Additionally, once the document is finalized, it’s essential to sign and secure it to prevent unauthorized alterations. Keeping track of document versions and revisions in pdfFiller ensures that the most current information is always available to stakeholders, facilitating clear communication and project tracking.

Case studies of successful clad metal implementations

Several industries have successfully integrated clad metal applications into their systems, demonstrating the effectiveness of these materials. In aerospace, manufacturers have used clad aluminum and titanium to improve component performance while reducing weight. The aviation sector has seen significant enhancements in fuel efficiency due to the optimized use of light but strong layers.

Automotive manufacturers have also innovated with clad metals, using copper-aluminum composites in electric vehicle components to enhance electrical conductivity while minimizing weight. These case studies reveal the profound impact of clad metal technologies—by balancing material properties, cost, and performance, companies can achieve more efficient and durable products.

Future trends in clad metal applications

The future for clad metal applications looks promising, given the ongoing innovations in this field. Emerging technologies, such as advanced welding techniques and new alloy compositions, are continually enhancing the capabilities of clad metals. Furthermore, industries are increasingly looking towards sustainability, with increased focus on recycling and using eco-friendly materials.

Market demand is also expected to grow, particularly in sectors such as renewable energy and electric vehicles. The versatile nature of clad metals positions them ideally to support evolving industry needs while significantly reducing material waste and enhancing product performance.

Expert insights and recommendations

Insights from industry leaders underscore the importance of leveraging clad metals effectively. Professionals recommend staying updated with the latest technologies and best practices to make informed decisions about material selection and processing methods. Quotes from experts highlight that collaboration between engineering and procurement teams can lead to better use of resources and optimized product performance.

Taking into account expert recommendations not only enhances the understanding of clad metal applications but also instills confidence in their use across various settings. The ability to adapt and innovate using clad metals can provide significant competitive advantages in today’s rapidly evolving industrial landscape.

Frequently asked questions about clad metal

Many users have questions regarding the clad metal applications form, especially concerning common pitfalls during the completion process. One of the most frequently asked questions is about the types of information that need to be gathered before filling out the form. It's recommended to clearly outline the specifications, purpose, and desired characteristics beforehand.

Additionally, addressing troubleshooting and guidance on form completion can be immensely helpful. Many users struggle with understanding technical jargon; thus, clear definitions and examples of required entries can alleviate confusion. pdfFiller offers robust support for users, ensuring they can efficiently submit their applications without unnecessary delays.

For pdfFiller’s FAQs

Below is a list of the most common customer questions. If you can’t find an answer to your question, please don’t hesitate to reach out to us.

How do I modify my clad metal applications in Gmail?

How do I make changes in clad metal applications?

How do I fill out the clad metal applications form on my smartphone?

What is clad metal applications?

Who is required to file clad metal applications?

How to fill out clad metal applications?

What is the purpose of clad metal applications?

What information must be reported on clad metal applications?

pdfFiller is an end-to-end solution for managing, creating, and editing documents and forms in the cloud. Save time and hassle by preparing your tax forms online.