Get the free Fibre, Fabric, and Form: Embedding Transformative Three-dimensionality in Weaving

Get, Create, Make and Sign fibre fabric and form

Editing fibre fabric and form online

Uncompromising security for your PDF editing and eSignature needs

How to fill out fibre fabric and form

How to fill out fibre fabric and form

Who needs fibre fabric and form?

Fibre fabric and form: Your comprehensive guide to textiles

Understanding fibre fabric

Fibre fabric serves as the foundational element in the textile industry, merging aesthetics with functionality. Defined as any material made from interlocking or weaving together various fibre strands, fibre fabric plays an integral role in creating clothing, home textiles, and industrial materials. The significance of fibre in textile production cannot be overstated, as it blends the artistic with the practical to yield innovative and durable fabrics.

The journey of fibre: from plant to fabric

Cultivating fibres begins with a careful selection of agricultural crops. Each fibre has its unique growing conditions; for example, cotton flourishes in warm climates, whereas flax, used for linen, requires cooler environments. Understanding the cultivation practices for each type of fibre is essential for sustainable production, which focuses on minimizing environmental impact while maximizing yield.

Once harvested, fibres undergo refining processes, including stripping, retting, and extraction to prepare them for the next phase. Techniques differ for plant fibres; for example, cotton harvesting involves mechanical pickers that remove both bolls and seeds, while flax is traditionally pulled by hand to facilitate retting — a decomposition process that separates the fibre from the stem.

Transforming fibres into yarn

The art of yarn production involves spinning — the process of twisting together fibre strands to create a continuous length suitable for textile production. Techniques vary, with ring spinning and open-end spinning being predominant. Ring spinning, often associated with finer yarns, delivers a smooth, high-strength filament. In contrast, open-end spinning yields bulkier yarns more suited for heavier fabrics.

Different types of yarn exhibit distinct characteristics that significantly impact the final fabric's performance. Textured yarns, for instance, offer elasticity and comfort, making them ideal for activewear, while smooth yarns provide a sleek finish suitable for formal apparel.

Weaving and knitting: creating fabric from yarn

Weaving serves as a primary technique for creating fabric from yarn, employing various methods to interlace strands. Common weave types include plain, twill, and satin, each imparting unique textures and aesthetics on the final material. Loom technology has advanced significantly, allowing for intricate designs and greater efficiency in larger production runs.

Knitting offers an alternative method to weaving, involving interlocking loops of yarn, which gives rise to stretchy, comfortable fabrics. This technique diverges from weaving in that it allows for a larger degree of flexibility and form fit, making it favorable for casual and athletic garments.

Finishing processes: enhancing fabric quality

Finishing techniques are pivotal in transforming raw fabric into a market-ready product. This stage significantly enhances the durability and functionality of the material while elevating its visual appeal. Common processes include bleaching, dyeing, and adding water-repellent treatments. Each method serves distinct purposes and can be adjusted to meet specific fabric requirements.

Dyeing can occur at various stages in the production process, such as piece dyeing, yarn dyeing, and direct dyeing. The choice of dye and method drastically affects the colour, texture, and even the utility of the final fabric, making it essential for designers to select the appropriate techniques when creating collections.

The role of technology in modern fabric production

The textile industry continually evolves through technological advancements that streamline production and improve sustainability. Innovative practices are emerging, particularly in sustainable fabric production, utilizing recycled materials and organic processes to reduce environmental footprints. Leading brands are now focusing on circular economy principles, where textiles are designed to be reused or biodegraded safely.

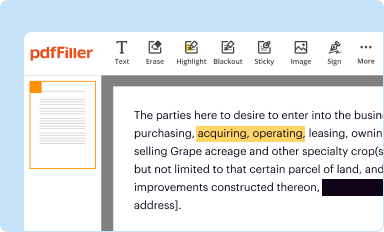

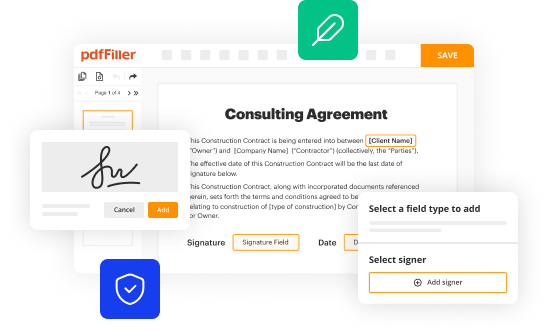

Interactive tools and cloud-based platforms, like pdfFiller, are becoming increasingly critical in fabric and form management. These tools enable designers and manufacturers to manage specifications, collaborate on projects, and streamline documentation processes efficiently, contributing to the industry's agility.

Utilizing pdfFiller for document management in fabric production

Navigating the complexities of fabric specifications is made easier with pdfFiller, a robust platform for document management in the textile sector. Users can seamlessly create, edit, and collaborate on fabric specs, ensuring all team members are on the same footing during the development process. This capability is particularly valuable in an industry where precise documentation can influence production timelines and outcomes.

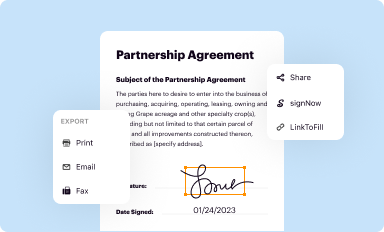

Moreover, managing contractual agreements with fabric suppliers is streamlined through eSigning features within pdfFiller. Ensuring secure signatures is critical in building trust and protecting interests in textile transactions, allowing businesses to move forward with confidence.

Exploring various fabric applications

Fabrics play diverse roles across various sectors; the fashion industry heavily relies on fibre fabric for creative expression while maintaining functionality. Apparel trends indicate a growing preference for sustainable fabrics and materials that offer comfort without compromising on style. Designers are increasingly experimenting with innovative fibre combinations and constructions to cater to a more conscious consumer base.

In home textiles, the choice of fabric influences everything from upholstery to bedding. Durability and specific characteristics, like stain resistance or breathability, are crucial in selecting fibres that both enhance aesthetics and meet functional requirements. As consumer preferences shift toward unique textures and sustainable options, the fabric industry must adapt, embracing these changes to meet evolving demands.

The future of fibre fabric

Sustainability emerges as a critical pillar in the future of fabric production. As awareness of environmental impacts grows, fabric manufacturers are prioritizing eco-friendly practices that minimize waste and promote sustainable sourcing. Innovations such as bio-based fibres, recycled materials, and sustainable dyeing techniques are setting the stage for a more responsible textile industry.

Furthermore, consumer trends towards uniqueness and personalization are influencing fabric production. The rise of custom fabric design and print-on-demand services allow consumers to express individuality in their choices. This shift highlights how consumers are increasingly participating in the design process, necessitating systems that can adapt to a dynamic marketplace.

Common challenges in fiber fabric creation

While the fabric industry is robust, it is not without its challenges. Supply chain disruptions, exacerbated by global events such as the pandemic, can lead to delays and increased costs in fibre availability. Manufacturers must navigate these issues, often needing to adapt sourcing strategies to maintain a consistent supply of quality materials.

Additionally, quality control remains a paramount concern in fabric production. Striking the right balance between cost and quality can be challenging, especially when competing in a fast-paced market. Effective strategies for maintaining high standards in production processes are necessary to uphold brand integrity and customer satisfaction.

For pdfFiller’s FAQs

Below is a list of the most common customer questions. If you can’t find an answer to your question, please don’t hesitate to reach out to us.

How do I edit fibre fabric and form online?

Can I create an electronic signature for the fibre fabric and form in Chrome?

How do I edit fibre fabric and form on an Android device?

What is fibre fabric and form?

Who is required to file fibre fabric and form?

How to fill out fibre fabric and form?

What is the purpose of fibre fabric and form?

What information must be reported on fibre fabric and form?

pdfFiller is an end-to-end solution for managing, creating, and editing documents and forms in the cloud. Save time and hassle by preparing your tax forms online.