Get the free Compression Springs Specification Form

Get, Create, Make and Sign compression springs specification form

Editing compression springs specification form online

Uncompromising security for your PDF editing and eSignature needs

How to fill out compression springs specification form

How to fill out compression springs specification form

Who needs compression springs specification form?

Compression Springs Specification Form: A Comprehensive How-to Guide

Understanding compression springs

Compression springs are mechanical devices designed to resist compressive forces. They are characterized by their coiled shape and ability to return to their original length after the compressive force is removed. This functionality allows compression springs to store potential energy and absorb shock, making them essential components in various mechanical systems.

These springs find applications in numerous industries including automotive, aerospace, medical devices, and electronics. For instance, in automotive applications, compression springs are utilized in suspension systems to ensure a smooth ride by absorbing bumps on the road. Their diverse applications underline the necessity for accurate specifications, as incorrect specifications can lead to product failures or performance issues.

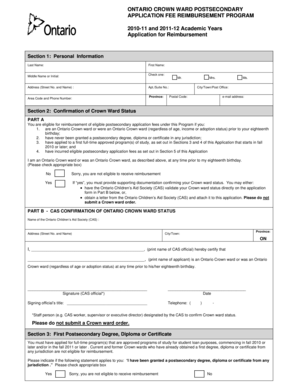

The compression springs specification form

The compression springs specification form serves as a crucial tool for documenting essential spring requirements. This standardized form streamlines the process of gathering necessary specifications, ensuring clarity and completeness in communication between stakeholders such as designers, engineers, and suppliers.

Key sections typically included in the form may encompass general project information, material requirements, mechanical properties, physical dimensions, and customization options. Using a standardized specification form helps minimize errors by providing a consistent structure for all parties involved in the manufacturing process.

Essential information to provide

Accurate and detailed information on the compression springs specification form is crucial for ensuring optimal spring performance. The first step is selecting the appropriate material. Common materials for compression springs include music wire, stainless steel, and oil-tempered wire. Each material comes with advantages and drawbacks, such as corrosion resistance, tensile strength, and cost-effectiveness.

Next, defining the load and spring rate is essential. The load requirement dictates how much weight the compression spring must support, while the spring rate, measured in pounds per inch (lb/in), indicates how much the spring compresses under a certain load. Understanding these parameters is vital for designing a spring that meets specific mechanical demands.

Additionally, specifying critical dimensions such as free length, wire diameter, and the number of active coils will influence the spring's functionality. The free length refers to the spring's length when no load is applied, while the wire diameter affects the spring's strength—thicker wire equates to higher strength and load capacity.

Detailed instructions for filling out the specification form

Filling out the compression springs specification form can be straightforward if approached methodically. Begin with the general information section, where you'll input contact details and provide a project overview. This context is helpful for engineers and suppliers to understand your needs.

Next, dive into material specifications. Common material types vary from high carbon steel to alloy steels. Each has different mechanical properties, so weigh the pros and cons. For example, while stainless steel offers excellent corrosion resistance, high carbon steel may provide better tensile strength for specific applications. This section should convey your preferred material and any reasons for that choice.

In the mechanical properties section, clearly state the load capacity and deflection characteristics required for your application. Specify how much load the compression spring needs to handle and the maximum allowable deflection for optimal performance.

Following this, focus on physical dimensions. Detailed measurements ensure precision in the final product. Use tools such as calipers for wire diameter and a ruler for free length to measure accurately. Finally, if applicable, indicate any additional customization options like coating or specific end types, such as closed or open ends, to enhance functionality.

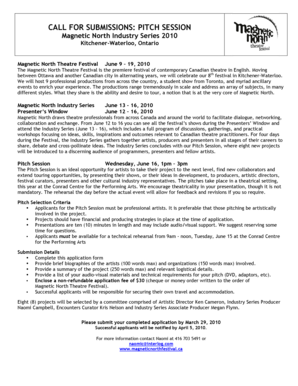

Visual aids and tools

To enhance the specification process, utilizing visual aids and tools can make a significant difference. Interactive tools available on platforms like pdfFiller can assist in specifying dimensions and visualizing compression springs. These tools often feature sliders to adjust parameters, helping you see the impact of changes real-time, making it easier to select the optimal design.

A visual guide to compression spring terminology can also clarify common terms such as free length, active coils, and spring rate. Diagrams illustrating these key features further assist in ensuring all parties have a mutual understanding of the specifications, reducing the likelihood of errors.

Common pitfalls in compression spring specifications

While filling out the compression springs specification form, several common pitfalls can arise. One major issue is misunderstanding load requirements. It's crucial to accurately gauge how much weight the spring is expected to bear and under what conditions. Miscalculating this can lead to springs that either fail to support the load or collapse under excessive strain.

Another frequent error involves incorrect measurement practices. Ensuring that measurements are accurate and repeatable is key to producing a reliable spring. This includes using the correct tools and methods to measure wire diameter, free length, and the number of active coils. Additionally, neglecting environmental factors, such as temperature or exposure to corrosive elements, however minor they may seem, can influence spring performance, potentially rendering them ineffective over time.

Best practices for collaboration with engineers and suppliers

Effective communication is vital when collaborating with engineers and suppliers. Transparency about your specifications using the compression springs specification form enhances understanding and reduces the chances of miscommunication. When sharing your specification form, provide supporting visual aids and diagrams whenever possible to illustrate key dimensions and requirements clearly.

Additionally, asking follow-up questions ensures that you and your suppliers are aligned on expectations and potential challenges. Utilize tools such as pdfFiller's collaborative platform, which allows multiple users to access, edit, and comment on documents in real-time. This fosters an environment where all parties can contribute insights and address concerns proactively.

Custom compression spring design assistance

There are instances when seeking professional assistance for custom compression spring design becomes essential. When the requirements of your project exceed standard sizes or configurations, engaging with experts can save time and resources.

Experienced engineers can offer insights into material selection, loading conditions, and spring design that align with your specific application. Many suppliers offer bespoke services where they consider your unique needs. Case studies showcasing successful custom designs can provide valuable examples of how tailored solutions can lead to optimal product performance.

Final checklist for compression spring specifications

As you finalize your compression springs specification form, consider this checklist to ensure you've covered all critical points. Ensure you've reviewed all material selections and mechanical properties. Confirm that all critical dimensions are accurately recorded and matched to your design requirements.

It's crucial to double-check all inputted information for consistency and accuracy. Lastly, ensure that any additional customizations are clearly defined. Submitting a thorough and complete specification can significantly impact the development and manufacturing phases.

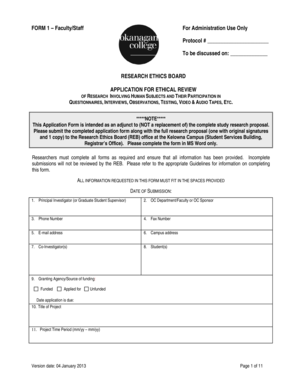

pdfFiller’s role in managing documentation

pdfFiller plays a pivotal role in managing and enhancing your documentation routines, especially when filling out a compression springs specification form. The platform provides a streamlined process for editing and signing forms, eliminating the typical hassle associated with paperwork.

With pdfFiller, teams can collaborate efficiently, making changes and leaving comments in real time. The cloud-based platform ensures you have access to your documents from anywhere, making it easier to manage revisions and updates as project needs evolve. The power of pdfFiller lies in its ability to keep your documentation organized and actionable, driving more efficient workflows.

For pdfFiller’s FAQs

Below is a list of the most common customer questions. If you can’t find an answer to your question, please don’t hesitate to reach out to us.

How do I complete compression springs specification form online?

Can I create an electronic signature for the compression springs specification form in Chrome?

Can I create an electronic signature for signing my compression springs specification form in Gmail?

What is compression springs specification form?

Who is required to file compression springs specification form?

How to fill out compression springs specification form?

What is the purpose of compression springs specification form?

What information must be reported on compression springs specification form?

pdfFiller is an end-to-end solution for managing, creating, and editing documents and forms in the cloud. Save time and hassle by preparing your tax forms online.