Get the free C153 Mechanical Joint Ductile Iron Fittings - Concord Supply

Get, Create, Make and Sign c153 mechanical joint ductile

How to edit c153 mechanical joint ductile online

Uncompromising security for your PDF editing and eSignature needs

How to fill out c153 mechanical joint ductile

How to fill out c153 mechanical joint ductile

Who needs c153 mechanical joint ductile?

C153 Mechanical Joint Ductile Form – How-to Guide

Overview of c153 mechanical joint ductile form

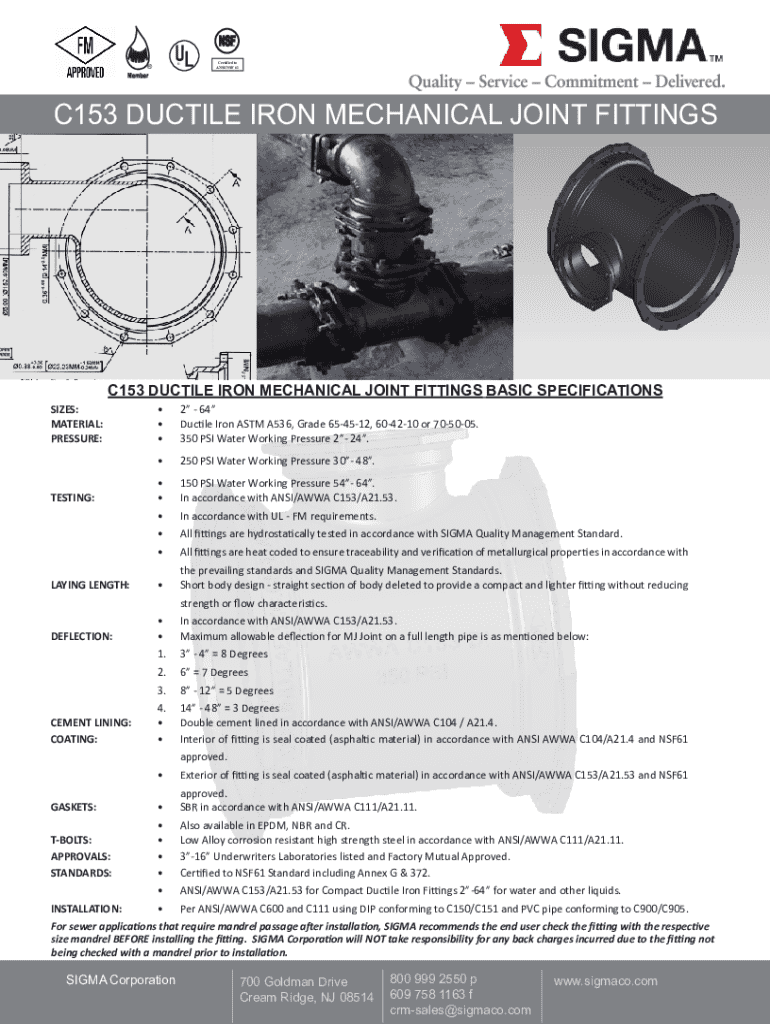

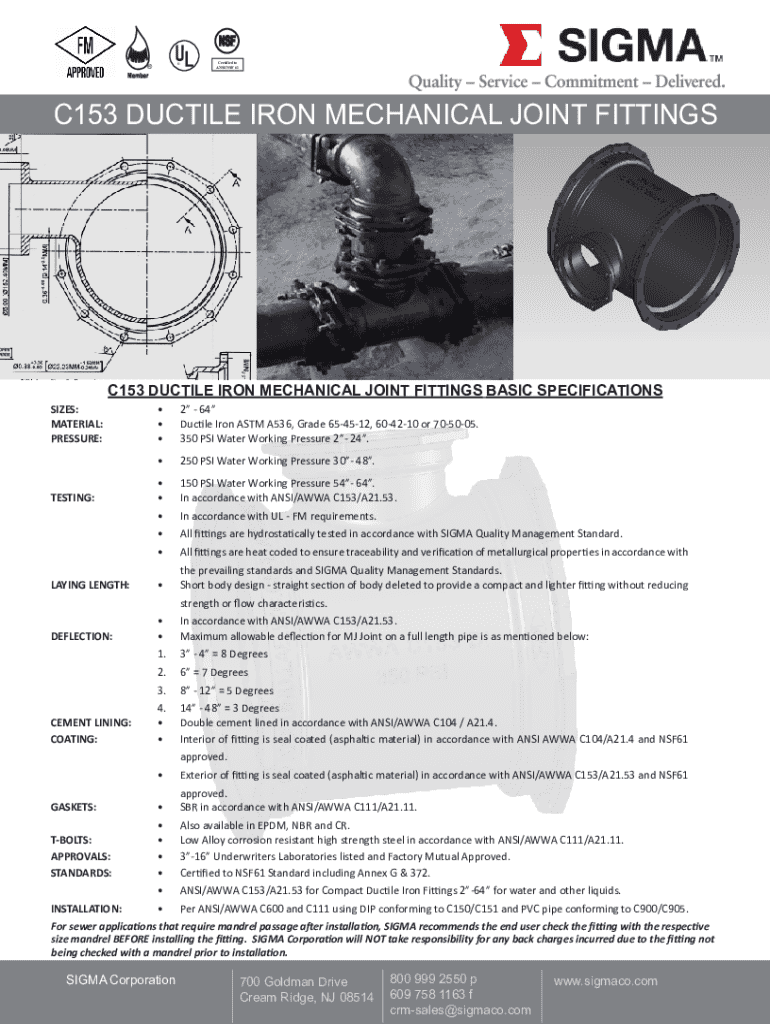

The c153 mechanical joint relates to ductile iron piping systems, specifically governed by the requirements set forth by the American Water Works Association (AWWA). This joint type is pivotal for providing reliable, leak-proof connections in various pipe installations, particularly in water and wastewater infrastructure.

Ductile iron's role in mechanical joints is fundamental due to its enhanced strength and flexibility compared to traditional gray iron. Its ability to withstand tensile and impact forces makes it an ideal choice, especially in dynamic conditions associated with municipal applications.

The relevance of c153 mechanical joints is particularly visible in municipal and utility sectors where non-leakage is critical. Applications include connections for water supply lines, sewer systems, and other essential utility pipelines.

Key features of c153 mechanical joint ductile form

The c153 mechanical joint boasts several features that enhance its utility and appeal. One notable attribute is its structural integrity and durability, allowing it to resist the forces of water pressure, earth movements, and thermal fluctuations. This reliability ensures longevity and reduces maintenance costs, making it an economical choice over its lifespan.

Moreover, ductile iron offers exceptional corrosion resistance, particularly when coated appropriately. This resistance is essential for installations in corrosive environments, such as wastewater treatment plants or areas with aggressive soil conditions, safeguarding against premature failure.

Another advantageous feature is the flexibility and adaptability of the c153 joint during installation. Its design allows for easy alignment and versatility in various piping configurations, accommodating different diameters and layouts without sacrificing efficacy.

Selecting the right c153 mechanical joint ductile form

Choosing the correct c153 mechanical joint requires attention to several critical factors. First, consider the diameter and size requirements necessary for your specific application. The measurable parameters must align with the pipe sizes you intend to use, ensuring a snug fit for efficiency.

Next, application specifics play a vital role; different conditions, such as low-pressure water lines versus high-pressure sewer applications, necessitate careful selection based on operational needs. Additionally, assess compatibility with existing systems to prevent coupling issues, particularly in retrofitting situations.

Lastly, check the performance ratings and standards corresponding to the selected joint. Referring to ANSI/AWWA C153 specifications will assure you that the products meet established quality and safety benchmarks.

Step-by-step installation guide for c153 mechanical joint ductile form

Preparation for installation

Prior to installation, a thorough site assessment is essential. Analyze specific conditions such as soil type, depth, and local infrastructure that may impact installation. This assessment informs installation strategies and tool requirements.

Gathering the necessary tools is equally important. Essential equipment includes a wrench, pipe cutter, and alignment tools. Ensure you have personal protective equipment (PPE) on hand for safety during the installation.

Installation process

To ensure proper alignment during installation, carefully position the pipes and joints. Start by slowly assembling the joint components, checking for alignment frequently to prevent issues that could lead to leaks.

Achieving a secure seal is crucial. Apply lubricant as recommended and tighten bolts according to the manufacturer's specifications. Avoid over-tightening, as this can lead to joint stress or failure.

Common pitfalls include misalignment and improper sealing. To avoid these issues, conduct regular checks during installation, ensuring each component fits well and tools are appropriately used.

Pressure testing

Once installed, effective pressure testing is imperative. Begin by pressurizing the joint according to specification, watching for signs of leaks or failures. Note that pressure should be raised gradually, allowing you to monitor for weaknesses.

Common testing equipment used includes pressure gauges and flow meters. Techniques vary, but typically include visual inspection and holding pressure for a designated time to identify leaks.

Maintenance and management of c153 mechanical joint ductile form

Maintenance practices for the c153 mechanical joint should include regular inspections to identify potential wear or damage. Check points of connection for signs of corrosion or leakage and ensure the integrity of seals remains intact, particularly in high-pressure applications.

Watch for signs of failure, such as excessive water pooling, which may indicate leaks, or visible rust around the joint. It’s important to document findings during each inspection to establish a history of performance and identify trends.

Best practices dictate the importance of routine cleaning and preservation of joint surfaces. Regular lubrication and protective coatings can extend the longevity of joints, ensuring reliable performance over time.

Troubleshooting common issues with c153 mechanical joint ductile form

Identifying and resolving leaks is essential for maintaining system integrity. Common initial signs include water seepage or pressure drops. Use diagnostic techniques, including soap water solutions, to detect bubbles that indicate the location of a leak.

Addressing structural failures starts with identifying the root cause of the issue, which may involve inspecting for corrosion or inappropriate installation techniques. Once found, solutions typically require either joint replacement or professional reinforcement.

In problem scenarios such as improper installation or unexpected shifts in soil conditions, having a troubleshooting plan is crucial. Documenting the issue and using industry-standard repair protocols can expedite resolution and minimize downtime.

Comparative analysis with other mechanical joints

When comparing ductile iron to alternative materials like PVC or steel, a clear picture of performance metrics emerges. Ductile iron provides superior strength and ductility, making it less prone to cracking than PVC, which may become brittle over time.

Cost analysis of ductile iron joints versus steel shows that while the initial investment for ductile iron may be slightly higher, its durability and lower maintenance requirements result in long-term cost savings.

Real-world applications further underscore these findings; numerous municipal projects have benefited from ductile iron's reliability over alternatives, showcasing success stories in high-demand environments.

Interactive tools and resources

To facilitate the installation and maintenance of c153 mechanical joints, several interactive tools are now available. An online calculator for joint sizing can aid engineers in selecting the appropriate sizes based on specific project parameters, enhancing accuracy and efficiency.

Moreover, an interactive diagram displays installation best practices, providing visual guidance to streamline the process. This approach allows for immediate understanding of complexities involved in each installation and regulatory requirements.

A dedicated FAQ section offers rapid answers to common queries, ensuring professionals can find solutions without extensive research, thus promoting effective decision-making.

eSigning and document management for professionals

Utilizing pdfFiller for document creation and collaboration greatly enhances the workflow surrounding c153 mechanical joint installations. This platform allows users to create installation documents, contracts, and manuals digitally, simplifying the process.

eSigning functionalities make it easy to sign off on contracts or completion documents electronically, promoting efficiency while reducing the need for paper-based processes.

Additionally, tracking changes through pdfFiller's document management features ensures that all stakeholders are up-to-date with the latest modifications, which is vital for maintaining compliance and accountability.

Advanced techniques and innovations in c153 mechanical joint technology

Recent developments in ductile iron joint design have focused on refining durability and performance metrics, adapting to contemporary challenges faced in municipal and utility applications. Innovations include advanced coating technologies that enhance corrosion resistance and reduce material fatigue.

Looking toward the future, emerging trends in smart infrastructure may soon integrate sensors into ductile iron joints to provide real-time data on system performance, allowing for proactive management and maintenance.

Insights from industry experts indicate that the demand for more sophisticated materials and solutions will drive ongoing research investments, promising exciting advancements in the technology surrounding the c153 mechanical joint.

For pdfFiller’s FAQs

Below is a list of the most common customer questions. If you can’t find an answer to your question, please don’t hesitate to reach out to us.

How do I edit c153 mechanical joint ductile online?

Can I create an electronic signature for the c153 mechanical joint ductile in Chrome?

How do I edit c153 mechanical joint ductile straight from my smartphone?

What is c153 mechanical joint ductile?

Who is required to file c153 mechanical joint ductile?

How to fill out c153 mechanical joint ductile?

What is the purpose of c153 mechanical joint ductile?

What information must be reported on c153 mechanical joint ductile?

pdfFiller is an end-to-end solution for managing, creating, and editing documents and forms in the cloud. Save time and hassle by preparing your tax forms online.