Get the free Press Welded Grating

Get, Create, Make and Sign press welded grating

Editing press welded grating online

Uncompromising security for your PDF editing and eSignature needs

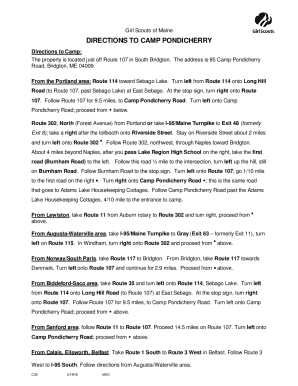

How to fill out press welded grating

How to fill out press welded grating

Who needs press welded grating?

Understanding and Managing Press Welded Grating Forms

Understanding press welded grating forms

Press welded grating refers to a type of grating known for its robust construction and versatility. It comprises interlocking metal bars that are joined through a welding process, making it a preferred choice for various industrial and commercial applications. The resulting product is characterized by its high load-bearing capacity and resistance to impact and deformation, which are vital attributes in demanding environments.

One of the most notable features of press welded gratings is their durability and strength. Made from materials like steel or aluminum, they are capable of enduring extreme conditions, including heavy foot traffic and intense weather elements. This longevity not only ensures safety but also reduces the need for frequent replacements, thereby enhancing cost-effectiveness.

The versatility of press welded grating forms extends to their wide range of applications. From flooring in industrial plants to platforms in commercial buildings, their adaptable nature makes them suitable for multiple environments. Furthermore, the designs can be customized, featuring various hole patterns and bar sizes to meet specific requirements.

The importance of using the right form

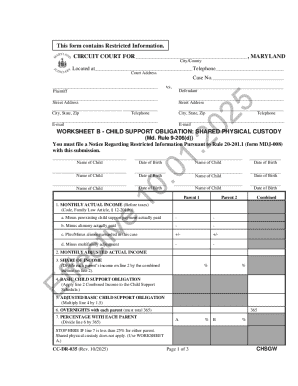

Using the correct press welded grating form is crucial in the document management process as it helps streamline workflows and ensures the accuracy of information capture. A well-structured form captures essential data points efficiently, reducing the likelihood of errors. This accuracy is particularly important when managing specifications for products like metal bar gratings or when detailing required applications for specific projects.

There are different types of grating forms available, each serving distinct purposes. Forms can vary from basic templates for simple applications to more complex designs that accommodate specific bar arrangements or additional features such as hole patterns for drainage or aesthetics. Choosing the right type not only simplifies the documentation process but also enhances the overall efficiency of project management.

How to fill out a press welded grating form

Filling out a press welded grating form correctly ensures that all necessary information is documented precisely. Here’s a step-by-step guide to help you complete the form using the pdfFiller platform efficiently.

Editing your press welded grating form

Once your press welded grating form is filled out, you might need to make changes. pdfFiller provides an array of editing tools to refine your document.

Using pdfFiller’s editing tools, you can modify existing text, add annotations, and insert comments for clarity. These features are particularly useful in collaborative environments where feedback is essential to the final product specifications.

Additionally, managing the version control of your form is vital. pdfFiller allows you to save multiple versions of your document, ensuring that changes can be tracked and reverted if necessary.

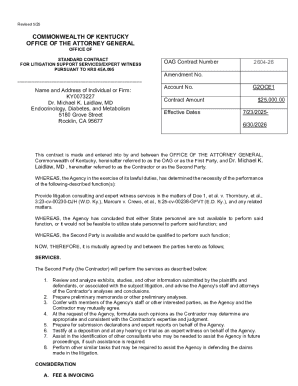

eSigning your press welded grating form

Implementing electronic signatures on your press welded grating form enhances the efficiency of the approval process. Electronic signatures not only speed up timeframes but also provide a secure means of creating binding agreements within your projects.

To add an eSignature to your press welded grating form using pdfFiller, follow these steps:

pdfFiller also emphasizes security in its eSigning process, offering encryption and authentication features to ensure that your signatures are protected and verifiable.

Collaboration tools for team management

Effective collaboration is essential when managing press welded grating forms, especially in a team setting. pdfFiller simplifies sharing documents and enables real-time collaboration, which is critical for maintaining project momentum.

You can easily share your completed forms with team members and stakeholders directly from the platform. Additionally, real-time collaboration features allow multiple users to edit the same document simultaneously, fostering better communication and faster decision-making.

Best practices for managing your press welded grating forms

To optimize the management of your press welded grating forms, implementing best practices is essential. Organizing your documents systematically can save time and ensure that important files are readily accessible.

Setting up notifications and reminders is another effective strategy, helping you keep track of deadlines and important tasks associated with your forms. Additionally, ensuring compliance and security around your documentation will safeguard sensitive information.

Troubleshooting common issues

While filling out your press welded grating form on pdfFiller, you may encounter common challenges. To navigate these, here are some tips that can help resolve issues effectively.

If problems persist, reach out to customer support solutions available on pdfFiller for personalized assistance.

Measuring effectiveness of your document management

Evaluating the effectiveness of your press welded grating forms within your document management system can significantly improve processes. Monitoring key metrics, such as time spent on form completion and the number of edits required, provides valuable insights into areas needing optimization.

Using this data, you can adjust your processes to enhance efficiency and reduce bottlenecks. Constantly refining your approach ensures that your team can work more productively and reduce time lost on document mismanagement.

Future trends in document management for press welded grating forms

As technology continues to evolve, the future of document management for press welded grating forms is likely to be shaped by innovations in form design and functionality. Enhanced integration with artificial intelligence (AI) and automation tools can lead to smarter document workflows, reducing the manual input required.

Users may find features that allow for predictive text entry, machine learning algorithms that suggest possible entries based on historical data, and automated compliance checks. These advancements could transform how organizations handle their press welded grating forms, paving the way for increased efficiency and accuracy.

For pdfFiller’s FAQs

Below is a list of the most common customer questions. If you can’t find an answer to your question, please don’t hesitate to reach out to us.

How do I edit press welded grating online?

How do I fill out the press welded grating form on my smartphone?

How do I fill out press welded grating on an Android device?

What is press welded grating?

Who is required to file press welded grating?

How to fill out press welded grating?

What is the purpose of press welded grating?

What information must be reported on press welded grating?

pdfFiller is an end-to-end solution for managing, creating, and editing documents and forms in the cloud. Save time and hassle by preparing your tax forms online.