Get the free Nova Glucometers Quality Control Record

Get, Create, Make and Sign nova glucometers quality control

How to edit nova glucometers quality control online

Uncompromising security for your PDF editing and eSignature needs

How to fill out nova glucometers quality control

How to fill out nova glucometers quality control

Who needs nova glucometers quality control?

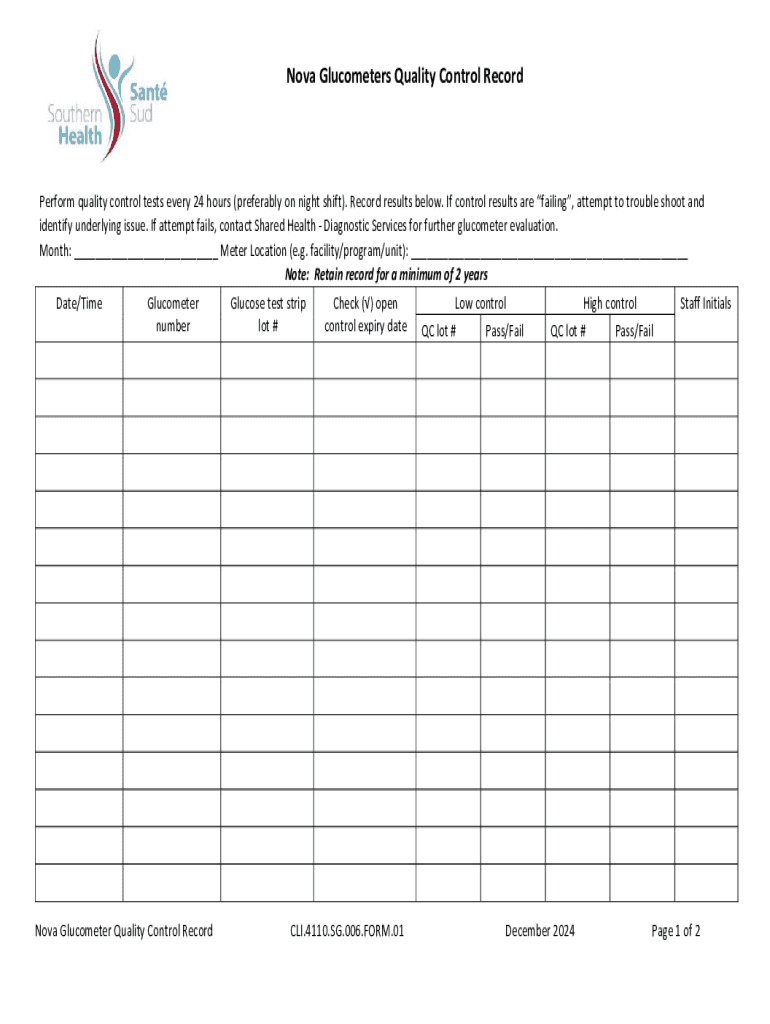

Nova glucometers quality control form: A comprehensive guide

Overview of Nova glucometers

Nova glucometers are designed to provide accurate blood glucose monitoring for individuals managing diabetes. Their reliability can significantly affect patient health outcomes, making it essential to ensure they function optimally. Quality control is crucial to verify the accuracy and reliability of the test results provided by these machines, as even slight discrepancies could lead to inappropriate treatment decisions.

Key features of Nova glucometers that require attention include their user-friendly design, integration with digital health tools, and advanced sensor technology. Effective quality control measures help detect any malfunctions or calibration issues before they affect patient care.

Objective of the quality control form

The primary goal of the Nova glucometers quality control form is to monitor the accuracy and overall performance of the devices. By tracking performance metrics, healthcare providers can ensure that patients receive reliable data on their blood glucose levels. This monitoring is vital not only for immediate clinical decisions but also for long-term diabetes management strategies.

Maintaining standards for diabetic management through rigorous quality control processes directly impacts treatment outcomes, adherence to medications, and overall patient safety. Hence, maintaining an accurate quality control form supports healthcare providers in achieving these crucial objectives.

Understanding the quality control process

Quality control within the context of glucometers refers to systematic activities implemented to guarantee that the devices function correctly and produce accurate and precise results. This involves regularly checking the glucometer’s performance against established standards.

Key metrics and parameters for evaluation include:

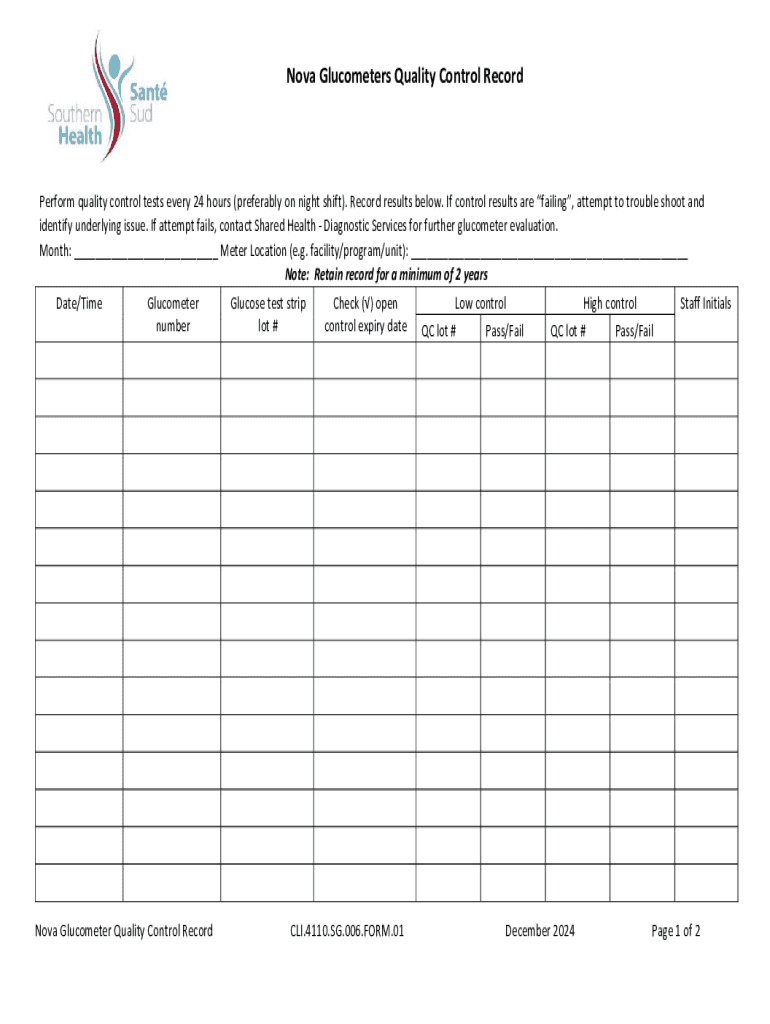

Components of the Nova glucometers quality control form

The Nova glucometers quality control form is structured to capture essential data that contributes to effective monitoring. It consists of several critical sections including:

Interpreting results from each section requires familiarity with typical performance benchmarks and ongoing adherence to quality standards. Accurate completion of these sections assists in ensuring the glucometer remains a dependable tool in diabetes management.

Step-by-step instructions for completing the quality control form

Completing the Nova glucometers quality control form is a structured process that ensures all necessary information is systematically gathered and documented. Start by preparing for the testing environment.

Next, proceed to fill out the form accurately:

Common issues and troubleshooting

While conducting the quality control tests, several potential problems may arise that could affect the reliability of the results. Common issues include inconsistent readings and the use of expired control solutions.

To address inconsistent readings, it’s important to ensure that the glucometer is calibrated and operating within its specifications. If readings still vary significantly, the device may need servicing.

Expired control solutions can significantly skew results, rendering quality control checks unreliable. Always check expiry dates and replace solutions as necessary to maintain testing integrity.

Compliance and regulatory guidelines

Maintaining adherence to health and safety standards is essential in the operation and management of glucometers. Organizations must stay informed about federal regulations and best practices for medical device quality management.

Compliance ensures that care providers uphold a high standard of safety and efficacy in diabetes management. This is crucial not only for patient trust but also for legal and ethical practice.

By understanding and implementing guidelines set forth by relevant authorities, healthcare facilities are better equipped to ensure the reliability of devices like Nova glucometers.

Documentation and record keeping

Accurate documentation is fundamental to effective quality control processes. Maintaining detailed records of all quality control activities supports clinical accuracy and provides necessary insights during audits or reviews of practices.

Best practices for long-term storage of quality control forms include:

Interactive tools and resources

pdfFiller offers several interactive tools designed to enhance document management efficiency. Users can easily find, edit, and collaborate on their quality control forms, streamlining the overall process.

Key features available on pdfFiller include:

Final review and quality assurance

Conducting a final review of the Nova glucometers quality control form is essential to ensure completeness before submission. This step includes looking for any missed entries or inaccuracies in recorded results.

Best practices for regular reviews of quality control processes include scheduling periodic audits of documentation and ensuring the entire team is familiar with the latest requirements for completing the form accurately.

Appendix

Included in this section is a sample Nova glucometers quality control form, which can serve as a valuable reference for staff. Additionally, a glossary of terms associated with glucometer quality control is beneficial for ensuring everyone understands the terminology used within the quality control process.

Document control

Maintaining an updated version history of the quality control form is essential for both usability and regulatory compliance. Additionally, establish a clear contact point for inquiries or support related to the quality control process or document management.

Feedback and reporting issues

Encouraging feedback on the quality control process supports an ongoing improvement culture. Establish a formal mechanism for reporting problems encountered during testing or documentation, ensuring prompt resolution and policy updates as necessary.

For pdfFiller’s FAQs

Below is a list of the most common customer questions. If you can’t find an answer to your question, please don’t hesitate to reach out to us.

Can I create an eSignature for the nova glucometers quality control in Gmail?

How do I edit nova glucometers quality control on an iOS device?

How do I edit nova glucometers quality control on an Android device?

What is nova glucometers quality control?

Who is required to file nova glucometers quality control?

How to fill out nova glucometers quality control?

What is the purpose of nova glucometers quality control?

What information must be reported on nova glucometers quality control?

pdfFiller is an end-to-end solution for managing, creating, and editing documents and forms in the cloud. Save time and hassle by preparing your tax forms online.