Get the free Compressed Air Leak Detection and Repair Application

Get, Create, Make and Sign compressed air leak detection

Editing compressed air leak detection online

Uncompromising security for your PDF editing and eSignature needs

How to fill out compressed air leak detection

How to fill out compressed air leak detection

Who needs compressed air leak detection?

A Comprehensive Guide to Compressed Air Leak Detection Forms

Understanding compressed air leaks

Compressed air leaks refer to any unintended release of compressed air from a system, which can lead to inefficiencies and increased operational costs. These leaks often occur in fittings, hoses, or any joints within the air delivery system. Their impact on operations can be significant, leading to energy losses and unplanned downtime.

Common causes of air leaks include worn-out seals, damaged hoses, and improper installation. Resolving these issues is critical to maintaining an efficient compressed air system.

Importance of detecting compressed air leaks

Detecting compressed air leaks is essential for both financial and environmental reasons. From a financial perspective, leaks can account for 20-30% of a facility's compressed air usage, leading to inflated energy bills and reduced productivity. Identifying and fixing leaks can result in significant cost savings.

Furthermore, detecting and repairing leaks contributes to environmental efficiency by reducing unnecessary energy consumption. This not only lowers operational costs but also supports sustainability goals, making it imperative for organizations to implement regular leak detection measures.

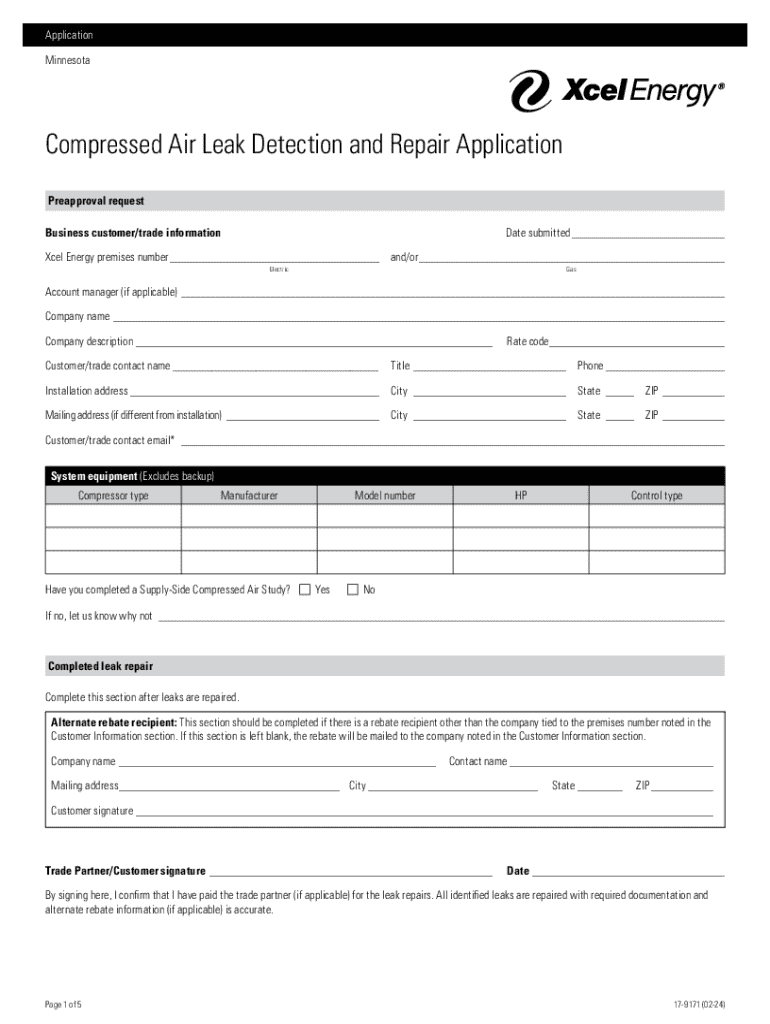

The role of a compressed air leak detection form

A compressed air leak detection form serves as a vital tool for standardizing leak detection processes. It is designed to ensure that all critical information is captured meticulously, which aids in both communication and accountability among teams.

Key components of the form typically include the location of the leak, an estimation of its size, date and time of detection, and personnel involved in the assessment. Optional fields can also be included for additional details, such as notes on operational impacts, which can provide valuable context for decision-makers.

Step-by-step guide to using the compressed air leak detection form

Preparation is crucial when filling out the compressed air leak detection form. Start by gathering necessary tools and equipment, such as ultrasonic leak detectors, wrenches, and gauges. Additionally, it is important to define team roles and responsibilities during leak detection to ensure an organized approach.

Filling out the form itself involves following a detailed walkthrough of each section. For instance, when estimating leak sizes, consider using visual or auditory assessments to gain a clear understanding of the severity. Recording observations effectively not only creates valuable data but also promotes accountability within the team.

Once the form is completed, it’s essential to review it for completeness and accuracy. Check each section against your findings and verify them with your team to ensure that all relevant information is accounted for.

Integrating the form into your workflow

Best practices for document management involve storing and organizing the completed compressed air leak detection forms in a centralized database. Leveraging cloud-based solutions like pdfFiller allows team members to access these forms from anywhere, ensuring easy retrieval when necessary.

Collaboration is key in resolving leaks effectively. Sharing findings and insights among team members can lead to improved communication and faster problem resolution. Utilizing collaborative tools within pdfFiller enhances this process, allowing teams to review forms together and coordinate maintenance efforts.

Advanced methods for air leak detection

In addition to using forms, technological solutions can enhance your leak detection process. By utilizing advanced tools such as ultrasonic leak detectors, teams can accurately locate leaks that are not visible to the naked eye. These devices can help identify leaks quickly, decreasing response time for repairs.

Integrating software for real-time leak monitoring can further optimize your compressed air system. It allows for continuous tracking, providing alerts when leaks exceed a certain threshold. In critical situations, seeking professional help from leak detection specialists might be necessary, particularly if the leaks are extensive or complex.

Case studies and success stories

Real-world examples of effective leak detection initiatives highlight the importance of systematic leak assessments. For instance, a manufacturing facility implemented a comprehensive leak detection program and reduced their compressed air costs by 30% within a year. Such initiatives not only lead to significant cost savings but also improve overall operational efficiency.

Quantifying results is essential in demonstrating the impact of leak detection efforts. Facilities reporting their findings have shown improved metrics such as reduced energy consumption and increased production uptime, making a compelling case for ongoing investment in leak detection programs.

Frequently asked questions (FAQ)

Common queries regarding the compressed air leak detection form center on its effective use. For example, facilities may wonder how often the form should be utilized. The frequency of usage often depends on the size of the operation and the complexity of the compressed air system, but regular check-ins are recommended—typically quarterly or whenever new equipment is introduced.

Other essential questions include identifying the signs of significant air leaks, such as decreased air pressure and unusual noises from machinery. Training your team on proper leak detection techniques is also crucial, ensuring that everyone understands the process and their role in it.

Leveraging pdfFiller for enhanced form management

Using pdfFiller for managing your compressed air leak detection forms provides numerous benefits. With online access available anytime and anywhere, your team can quickly fill, edit, and collaborate on forms without being tied to a specific location. This flexibility enhances productivity and ensures that documents are always up to date.

Interactive features within pdfFiller, such as templates for standard forms and collaborative tools for team reviews, can help maximize efficiency. Learning from examples of how other teams have streamlined their processes illustrates the practical applications of these tools in achieving effective leak detection operations.

For pdfFiller’s FAQs

Below is a list of the most common customer questions. If you can’t find an answer to your question, please don’t hesitate to reach out to us.

How can I modify compressed air leak detection without leaving Google Drive?

How can I send compressed air leak detection for eSignature?

How do I edit compressed air leak detection straight from my smartphone?

What is compressed air leak detection?

Who is required to file compressed air leak detection?

How to fill out compressed air leak detection?

What is the purpose of compressed air leak detection?

What information must be reported on compressed air leak detection?

pdfFiller is an end-to-end solution for managing, creating, and editing documents and forms in the cloud. Save time and hassle by preparing your tax forms online.