Get the free Installation, Operation, and Maintenance of Carbon ... - webdelprofesor ula

Get, Create, Make and Sign installation operation and maintenance

How to edit installation operation and maintenance online

Uncompromising security for your PDF editing and eSignature needs

How to fill out installation operation and maintenance

How to fill out installation operation and maintenance

Who needs installation operation and maintenance?

Installation operation and maintenance form: A complete guide

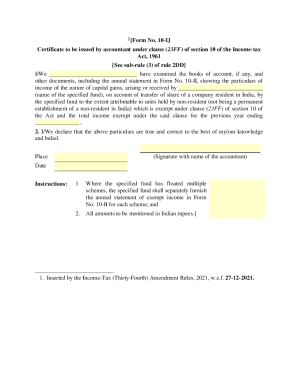

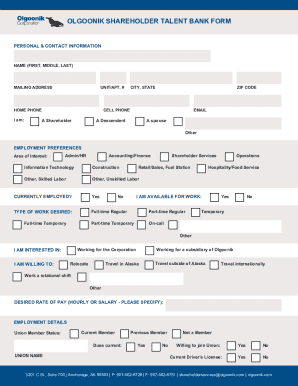

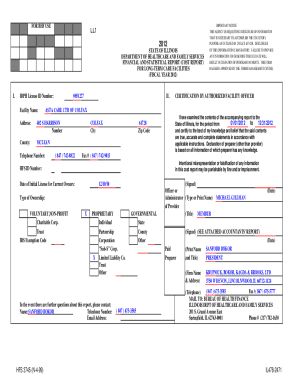

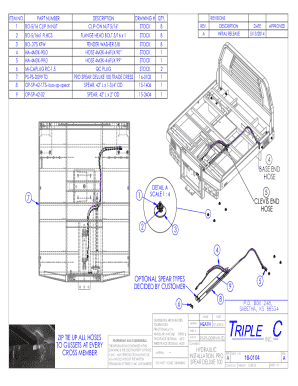

Understanding the installation operation and maintenance form

An installation operation and maintenance form, often abbreviated as O&M form, is a crucial document that ensures smooth functioning and longevity of equipment post-installation. This form serves multiple purposes—from outlining operational guidelines to detailing maintenance procedures and safety regulations. By clearly defining each aspect related to the equipment's lifecycle, the form helps in maintaining coherence between all stakeholders.

Proper management of installation operation and maintenance forms is vital. Documentation issues can lead to operational inefficiencies, safety hazards, and potential compliance violations. Therefore, ensuring that such forms are meticulously completed, updated, and stored is essential for maintaining operational effectiveness.

Key components of the installation operation and maintenance form

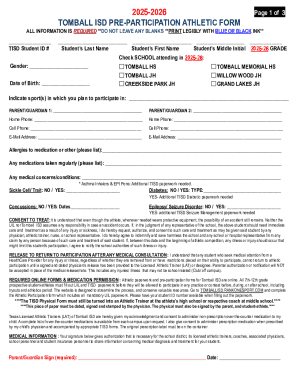

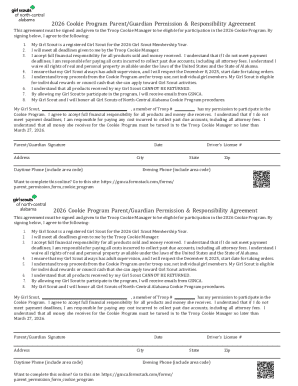

A well-structured installation operation and maintenance form includes several essential sections that cater to the diverse needs of maintenance personnel, engineers, and compliance officers. Understanding these components lays the foundation for effective use.

Types of installation operation and maintenance forms

Installation operation and maintenance forms can vary based on industry needs. Different sectors often have tailored requirements that reflect their operational complexities.

It's important to note that installation operation and maintenance forms can feature customizable elements. Each business can adapt the template according to its specific operational protocol, making them versatile across different contexts.

Benefits of using an installation operation and maintenance form

Utilizing an installation operation and maintenance form brings numerous benefits that enhance operational efficiency and safety.

How to create an installation operation and maintenance form

Creating an effective installation operation and maintenance form requires attention to detail and a clear understanding of the operational requirements. This section provides a step-by-step guide.

In addition to the steps above, be mindful of the need for accuracy and completeness; vague or incomplete forms can lead to operational disruptions.

How to edit and customize installation operation and maintenance forms

Editing and customizing installation operation and maintenance forms is essential for keeping them relevant and effective. With tools available on platforms like pdfFiller, users can easily modify these forms.

Additionally, collaborative features on platforms allow team members to provide input, ensuring that the form captures diverse operational insights.

Signing the installation operation and maintenance form

Digital signatures have transformed document management, making processes faster and more secure. Signing the installation operation and maintenance form adds a level of accountability amongst users.

Managing your installation operation and maintenance forms

Effective management of installation operation and maintenance forms hinges on organization and accessibility. Cloud storage solutions enable users to keep documents readily available.

Common mistakes to avoid with installation operation and maintenance forms

Even with careful planning, some pitfalls can undermine the efficiency of installation operation and maintenance forms.

Examples of effective installation operation and maintenance forms

Real-world case studies highlight effective implementation of installation operation and maintenance forms across various industries. These examples illustrate best practices and the tangible benefits gained from implementing structured O&M forms.

Visual samples of well-designed forms can provide a benchmark for users looking to improve their document structure. Testimonials from users also reveal the efficiency gained through platforms like pdfFiller, which streamline the process of form management.

FAQs about installation operation and maintenance forms

Despite the clarity of documentation practices, users often have common queries regarding installation operation and maintenance forms.

Leveraging technology for enhanced document management

Modern technology transforms the management of installation operation and maintenance forms, making it more efficient and accessible. Utilizing digital tools can elevate document management practices.

For pdfFiller’s FAQs

Below is a list of the most common customer questions. If you can’t find an answer to your question, please don’t hesitate to reach out to us.

How can I send installation operation and maintenance to be eSigned by others?

Where do I find installation operation and maintenance?

How do I complete installation operation and maintenance on an Android device?

What is installation operation and maintenance?

Who is required to file installation operation and maintenance?

How to fill out installation operation and maintenance?

What is the purpose of installation operation and maintenance?

What information must be reported on installation operation and maintenance?

pdfFiller is an end-to-end solution for managing, creating, and editing documents and forms in the cloud. Save time and hassle by preparing your tax forms online.