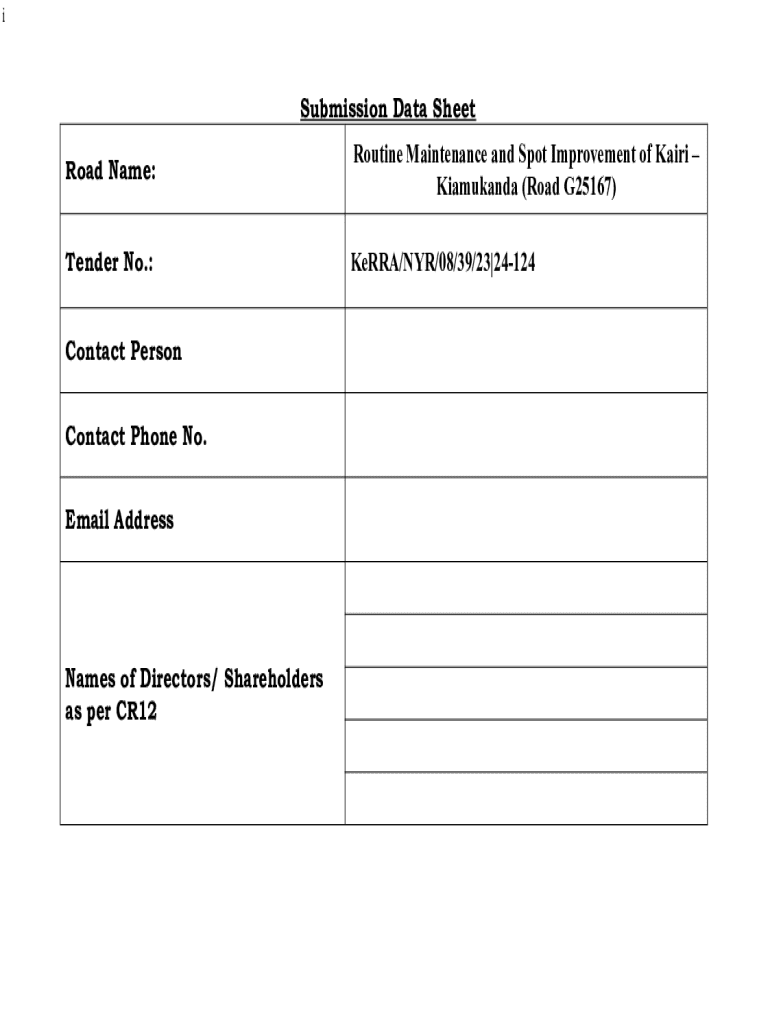

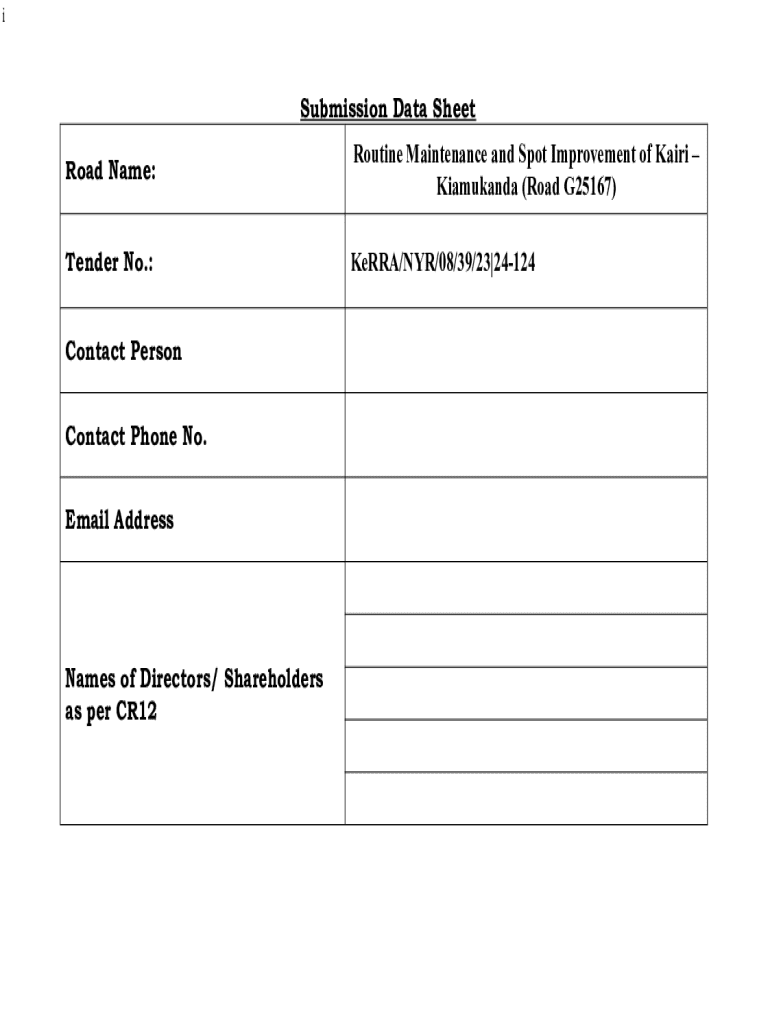

Get the free Routine Maintenance and Spot Improvement of Kairi... - kerra go

Get, Create, Make and Sign routine maintenance and spot

Editing routine maintenance and spot online

Uncompromising security for your PDF editing and eSignature needs

How to fill out routine maintenance and spot

How to fill out routine maintenance and spot

Who needs routine maintenance and spot?

Routine Maintenance and Spot Form: A Comprehensive Guide

Understanding routine maintenance

Routine maintenance refers to the scheduled upkeep of equipment and infrastructure aimed at preventing unexpected failures and prolonging asset longevity. It encompasses a range of practices that ensure machines and systems operate at optimal efficiency.

The importance of routine maintenance cannot be overstated. By adhering to a well-defined maintenance program, organizations can significantly minimize downtime and avoid costly repairs that arise from neglected equipment. Regular maintenance keeps assets in peak condition, ensuring they perform as intended and supporting overall operational efficiency.

Spot form: What is it and why use it?

A spot form is a streamlined document tool used in maintenance contexts to capture essential information at the point of service. Its purpose is to collect data about maintenance tasks, inspections, and other operational activities in real time.

Using a spot form provides numerous benefits. Firstly, it streamlines information collection, reducing the likelihood of errors and omissions that can occur when recording data. It enhances accuracy in maintenance records and paves the way for improved communication among team members involved in the maintenance process.

Furthermore, spot forms integrate seamlessly into routine maintenance practices. They enable maintenance teams to report issues immediately and collect real-time data that can influence operational decisions.

Key components of a spot form

An effective spot form should contain several essential fields to ensure clarity and comprehensive data capture. Key components include:

Customization options for spot forms can include adding fields tailored to specific equipment types or departmental requirements. This adaptability helps ensure that the spot forms meet the diverse needs of various teams and improve overall effectiveness.

How to create an effective spot form

Creating an effective spot form involves several steps. Begin by identifying the critical information that must be captured during maintenance activities. This can guide you in developing a focused and relevant form.

Ensure clarity and usability by keeping the form simple and intuitive. Use descriptive labels for each field and consider incorporating checkboxes for quick selections, making data entry efficient.

Best practices for using spot forms in routine maintenance

For spot forms to be effective in routine maintenance, training your team on their efficient use is paramount. Conducting workshops and offering ongoing education ensures that employees understand how to leverage spot forms for maximum impact.

Regularly review and update spot forms to reflect changes in maintenance processes or operational needs. This evaluation helps identify modifications based on usage trends, ensuring that your spot forms remain relevant and useful.

Lastly, incorporating spot forms into your broader maintenance management system can greatly enhance data management. Leveraging digital solutions can provide cloud-based storage and facilitate integrated workflows that improve efficiency.

Case studies: Successful implementation of routine maintenance and spot forms

In the manufacturing sector, routine maintenance and spot forms played a crucial role in overcoming challenges related to equipment downtime. One company implemented spot forms for daily inspections, enabling the maintenance team to address minor issues before they escalated into major problems, thereby improving operational efficiency.

Similarly, in facility management, routine maintenance practices supported by spot forms resulted in remarkable cost savings. By keeping meticulous records of inspections and repairs, facility managers identified recurring issues and optimized resource allocation, further enhancing the life cycle of their assets.

Common mistakes to avoid with spot forms

While spot forms can significantly enhance maintenance processes, there are common pitfalls to avoid. Neglecting regular updates can render spot forms ineffective, as outdated information may lead to costly errors or oversights.

Another mistake is overcomplicating the form structure. While detailed data is valuable, a cumbersome format may discourage consistent use. It’s essential to strike a balance between capturing necessary information and maintaining usability.

Additionally, failing to analyze the data collected through spot forms can result in missed opportunities for improvement. Regular data review allows maintenance teams to identify trends and patterns vital for informed decision-making.

Leveraging technology in routine maintenance and spot forms

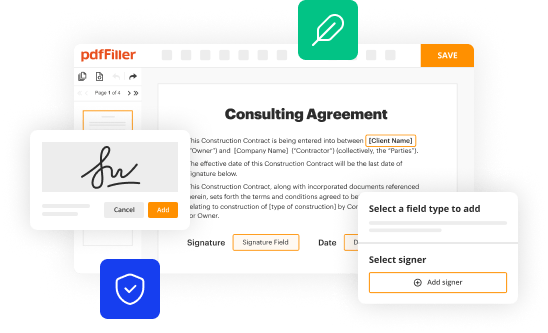

The advent of technology has transformed the way spot forms are designed and used. Using platforms like pdfFiller, teams can create digital spot forms that are easily editable and accessible from anywhere. This flexibility facilitates collaboration among team members, leading to more efficient maintenance workflows.

Digital spot forms not only enhance data management but also offer editing capabilities and features that empower users to customize their forms. Collaborating on forms becomes seamless, allowing for quicker resolutions to maintenance issues.

Integrating spot forms with cloud solutions means that data generated during maintenance activities is readily available for analysis. This integration supports streamlined workflows, reduces errors in data entry, and promotes a culture of accountability within maintenance teams.

Future trends in routine maintenance and spot form usage

As industries evolve, so do the methodologies surrounding routine maintenance and spot forms. Emerging technologies such as artificial intelligence and machine learning are beginning to influence predictive maintenance insights, allowing organizations to anticipate equipment failures with unprecedented accuracy.

Furthermore, document management practices are set to evolve towards greater digitization and automation. The role of digital transformation in maintenance processes will streamline data handling and enhance accessibility, enabling teams to work smarter, not harder, in managing assets.

Overall, embracing these future trends will enable organizations to enhance their maintenance programs and optimize their use of spot forms, leading to improved asset reliability and organizational efficiency.

For pdfFiller’s FAQs

Below is a list of the most common customer questions. If you can’t find an answer to your question, please don’t hesitate to reach out to us.

How can I edit routine maintenance and spot from Google Drive?

How do I complete routine maintenance and spot on an iOS device?

Can I edit routine maintenance and spot on an Android device?

What is routine maintenance and spot?

Who is required to file routine maintenance and spot?

How to fill out routine maintenance and spot?

What is the purpose of routine maintenance and spot?

What information must be reported on routine maintenance and spot?

pdfFiller is an end-to-end solution for managing, creating, and editing documents and forms in the cloud. Save time and hassle by preparing your tax forms online.