Get the free What is a board portal

Get, Create, Make and Sign what is a board

Editing what is a board online

Uncompromising security for your PDF editing and eSignature needs

How to fill out what is a board

How to fill out what is a board

Who needs what is a board?

What is a board form?

Understanding board forms

A board form refers to a crucial component in the construction and design landscape, primarily utilized for shaping concrete structures. These forms, typically made from various materials, allow builders to create the desired depth and dimensions of concrete elements, such as walls and slabs. Simply put, a board form acts as a temporary mold for pouring concrete, ensuring that the rawness of the concrete maintains a precise configuration that holds up over time.

Historically, the utilization of board forms has evolved significantly. In the past, wood was predominantly the material of choice, with builders relying on its availability and ease of manipulation. However, the industry has seen a shift towards more durable materials, such as metal and plastic, which offer greater longevity and adaptability. Innovations in formwork technology have allowed for more complex shapes and finishes, adapting to modern architectural demands.

Characteristics of board forms

Board forms come in various material compositions, each offering unique characteristics tailored to different construction needs. Commonly used materials include wood, which provides a traditional approach; metal, known for its durability and reusability; and plastic, appreciated for its lightweight nature and versatility. Each material uniquely impacts the board forms' performance and the final finish of the concrete structure.

Moreover, board forms can be categorized into several design variations, including standard, reusable, and custom forms. Standard forms are often used for typical applications, while reusable forms are designed for multiple uses, enhancing sustainability. Custom forms are tailored specifically for unique construction projects, providing a precise fit for complex architectural designs. Understanding these variations is vital for selecting the right form for your project.

Durability and maintenance of board forms largely depend on the material used and how these forms are cared for. For instance, wooden forms can warp if not properly maintained, while metal forms may require regular inspections for corrosion. Regular maintenance extends the lifespan of board forms, allowing construction professionals to maximize their investment and minimize waste.

Applications of board forms

Board forms find extensive applications in various project types, with residential construction often leading the way. For home foundations and walls, board forms allow for straightforward and efficient concrete pouring. The versatility of these forms ensures that they can easily adapt to the varying depths and heights required in traditional housing structures, contributing to both functionality and aesthetic appeal.

In commercial projects, board forms are integral to creating durable infrastructure, from office complexes to bridges. The rigorous requirements of commercial construction call for robust board forms that can withstand the pressures of significant concrete pourings, helping to create resilient wall surfaces and structural elements. Furthermore, innovative artistic applications are emerging, as architects and designers utilize board forms in sculptural projects, enhancing the visual narrative of public spaces and installations.

Advantages of using board forms

Utilizing board forms presents notable advantages in construction. First, these forms are often a cost-effective solution, enabling builders to achieve high-quality concrete structures without excessive expenditures. The ability to reuse forms across multiple projects leads to significant savings, thus making the overall process more economical. Moreover, the variety of materials offers diverse price points, catering to different budgets.

Flexibility and customization are two other key benefits. Board forms can easily be tailored to specific project needs, particularly in custom builds where uniqueness is paramount. This adaptability not only enriches design possibilities but also ensures that engineers and architects can create structures that meet precise specifications. Additionally, board forms are noted for their ease of use; they can be assembled and disassembled quickly, streamlining the construction process.

How to effectively use board forms

Successfully utilizing board forms in your construction projects requires a structured approach. First, begin with meticulous planning of your project. It’s vital to select the right board form based on factors such as the intended design, material choice, and depth of the concrete pour. This careful consideration will pave the way for a smooth construction process.

Once planning is complete, proceed to procure high-quality materials. Sourcing board forms from reputable suppliers ensures that you receive a product that meets safety standards and performance requirements. After securing your materials, the next step is setting up the board forms. It involves assembling the panels correctly, aligning them accurately, and ensuring they are properly braced to withstand the concrete’s weight.

Following the setup, the process of pouring concrete can commence. Best practices include pouring in manageable increments to prevent form movement and allowing adequate time for curing to develop the concrete's strength. After the concrete has cured sufficiently, safely remove the board forms, which can often be reused in future projects with careful handling. Reassembly and disassembly techniques are vital for preserving the integrity of the forms for continued use.

Innovations in board form technology

The construction industry is not static; innovations continuously reshape the landscape of board form technology. Advancements in materials, such as high-strength composites, have introduced products that enhance performance while reducing environmental impact. These materials often offer improved resistance to moisture and wear, expanding the operational lifespan of board forms and contributing to more sustainable construction practices.

Moreover, digital tools for design are revolutionizing how boards are conceptualized and utilized. Software and applications designed for architectural planning facilitate the accurate modeling of board forms, allowing for precise adjustments before physical production begins. This proactive strategy minimizes waste and enhances efficiency. Environmentally conscious practices, such as using recycled materials for board forms, are becoming increasingly prevalent, aligning with the growing demand for green building solutions.

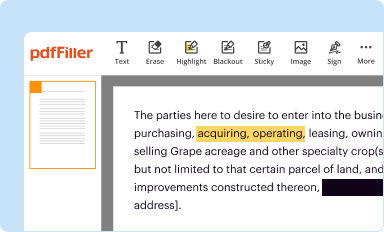

Collaboration and document management

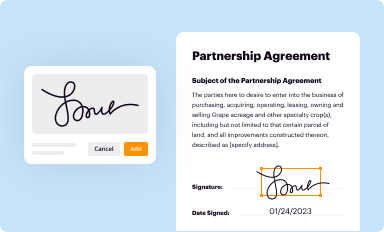

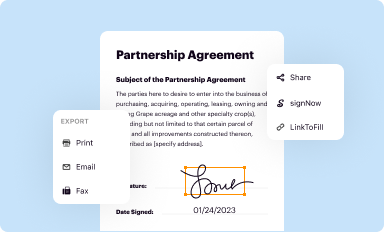

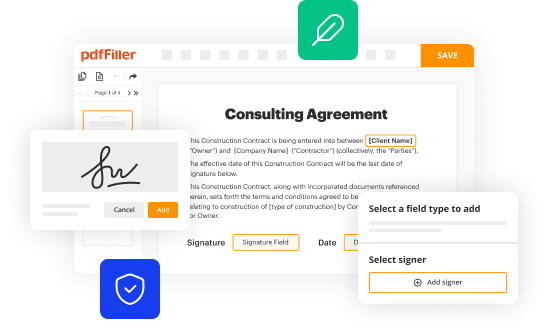

Managing documentation related to board forms can significantly impact project efficiency, and tools like pdfFiller offer robust solutions. Using pdfFiller, users can edit and manage templates associated with board forms effortlessly, ensuring all paperwork remains organized and accessible. This capability is essential for all teams involved in construction, as it fosters better collaboration among stakeholders.

Furthermore, collaboration features enable teams to work together effectively on board form projects, allowing for real-time updates and feedback. The inclusion of e-signature capabilities streamlines the approval process for board form documentation, ensuring that all necessary rights and permissions are secured without delay. The synergy of these tools not only enhances productivity but also supports transparent communication across project teams.

Real-world case studies

Examining successful implementations of board forms can provide valuable insights into their practical applications. For instance, a renowned commercial skyscraper utilized board forms to create intricate concrete facades, showcasing unique grain patterns that captivated onlookers. Such projects illustrate the potency of board forms in achieving innovative design while maintaining structural integrity.

In another case, a public art installation effectively incorporated board forms to create dynamic shapes that stood out in the urban landscape. This not only emphasized the artistic element of construction but also demonstrated the versatility of board forms beyond traditional applications. Analyzing these examples reveals lessons learned regarding material choice, design innovation, and the importance of collaboration in ensuring the successful execution of board form projects.

Frequently asked questions (FAQ)

Many individuals have queries related to board forms, encompassing their uses and best practices. For example, a common question pertains to the ideal type of material for specific applications. Generally, wood is excellent for small residential projects, while metal forms may be more suitable for larger commercial structures. Potential users often express concerns about the reusability of board forms after their initial use; however, by following proper maintenance practices, many forms can be reused multiple times.

Another frequently asked question revolves around the time it takes to remove board forms after the concrete has set. Generally, forms can be removed after 24 to 48 hours, but this timeframe can vary depending on environmental conditions and the specific concrete mix used. Misconceptions persist about the complexity of using board forms, yet, with appropriate planning and guidance, even novice builders can successfully integrate board forms into their projects.

Next steps for your board form project

As you embark on your board form project, consider exploring further resources available on pdfFiller, which provides comprehensive tools for document creation and management. The insights derived from this guide will serve as a solid foundation as you evaluate the different board forms suitable for your upcoming projects. With careful planning, effective collaboration, and a thorough understanding of available options, your application of board forms can be both innovative and efficient.

For pdfFiller’s FAQs

Below is a list of the most common customer questions. If you can’t find an answer to your question, please don’t hesitate to reach out to us.

How can I modify what is a board without leaving Google Drive?

How can I send what is a board for eSignature?

Can I edit what is a board on an Android device?

What is what is a board?

Who is required to file what is a board?

How to fill out what is a board?

What is the purpose of what is a board?

What information must be reported on what is a board?

pdfFiller is an end-to-end solution for managing, creating, and editing documents and forms in the cloud. Save time and hassle by preparing your tax forms online.