Get the free Plant Industry - Inspection and Compliance Activities

Get, Create, Make and Sign plant industry - inspection

How to edit plant industry - inspection online

Uncompromising security for your PDF editing and eSignature needs

How to fill out plant industry - inspection

How to fill out plant industry - inspection

Who needs plant industry - inspection?

Plant Industry - Inspection Form: A Comprehensive Guide

Understanding the plant industry inspection process

The plant industry is governed by a series of regulations and standards that ensure safety, quality, and compliance across operations. These regulations encompass a wide range of practices from cultivation to processing and distribution. Adhering to these safety regulations is paramount as it not only protects workers but also ensures product safety for consumers. Regulatory bodies such as the U.S. Department of Agriculture (USDA) and the Environmental Protection Agency (EPA) play key roles in the oversight of these operations. They establish guidelines that must be followed during inspections, which are crucial for maintaining quality and compliance.

Various types of inspections take place within the plant industry, each serving a specific purpose. Routine inspections are carried out regularly to monitor ongoing compliance. Compliance inspections, on the other hand, focus on adherence to specific regulations and can be triggered by previous violations. Safety audits assess the effectiveness of safety protocols and are essential for risk management. Understanding these different inspection types is critical for anyone involved in the plant industry.

Importance of a comprehensive inspection form

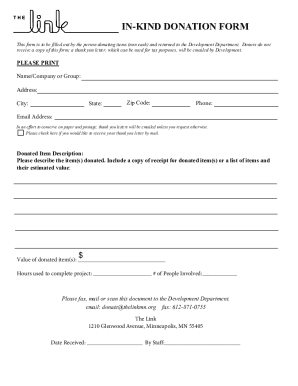

A comprehensive inspection form serves as a vital tool in quality control, helping to assure the integrity and safety of products throughout the supply chain. By meticulously documenting compliance with industry standards, inspection forms facilitate transparency and accountability. They also provide a structured way to record findings, making it easier to manage compliance over time.

In today's fast-paced environment, using electronic inspection forms offers substantial benefits. These forms are accessible from any device, allowing teams to collaborate in real-time. Cloud storage enables enhanced collaboration, as documents can be shared easily among team members. Additionally, real-time data collection and analysis help organizations promptly respond to any safety or compliance issues, ultimately improving workplace health standards.

Components of an effective plant industry inspection form

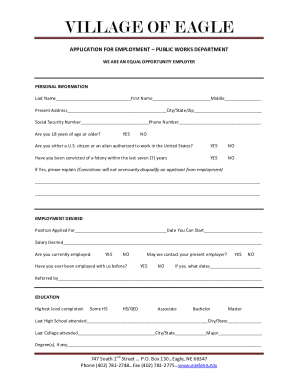

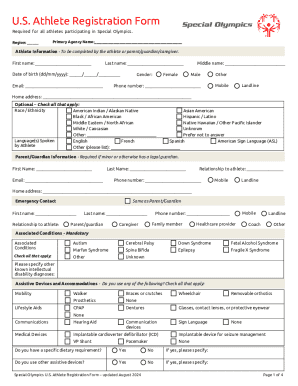

To effectively serve its purpose, an inspection form must include several essential sections. General information such as the date, location, and inspector’s name is fundamental, as it lays the groundwork for recording and tracking inspections over time. The form should contain detailed sections on the equipment and facilities being inspected, accompanied by compliance checklists that specify what to look for. Moreover, there should be dedicated areas for observations and findings, allowing inspectors to jot down critical insights during their assessments.

Including special features can significantly enhance the efficacy of the inspection form. Digital signature fields ensure compliance by allowing inspectors and managers to formally acknowledge findings and action plans. Interactive elements like dropdown menus and checkboxes make navigation easier, especially on mobile devices. Providing space for corrective action plans encourages teams to outline and track improvements based on inspection outcomes.

How to fill out the plant industry inspection form

Filling out a plant industry inspection form requires a structured approach to ensure accuracy and completeness. First, gather necessary information such as prior reports and regulatory documentation to inform your evaluation. Next, start by filling in the general information that establishes the context of the inspection.

The next step involves evaluating equipment and facilities. Pay close attention to the checklist items, as they guide what aspects need verification. Common pitfalls include overlooking minor discrepancies that can escalate into larger issues if not addressed. Documenting observations clearly is vital; aim for concise yet detailed notes that convey the findings effectively. If you encounter areas needing improvement, detail these observations as they form the basis for corrective actions. Lastly, conduct a final review before submitting the form to ensure all sections are complete and accurate.

Managing and storing inspection forms

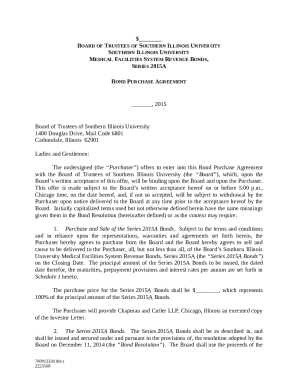

Shifting from traditional paper inspection forms to digital solutions can significantly improve the management of inspection data. Utilizing platforms like pdfFiller provides numerous benefits, including seamless integration of forms with cloud storage, ensuring easy access for team members. Uploading and storing forms in pdfFiller is straightforward and ensures that data is organized for easy retrieval when needed.

Maintaining a centralized database of inspections is essential for streamlined operations. This entails organizing files in a way that allows for easy access and implementing effective search functionalities to quickly retrieve past inspection reports. Additionally, ensuring data security and compliance is of utmost importance. Employing encryption and understanding cloud security protocols will protect sensitive data from breaches, thus safeguarding the organization’s operations and reputation.

Leveraging inspection data for continuous improvement

Analyzing inspection data can unlock insights into patterns and trends that may indicate underlying issues within the plant's operations. Identifying recurring problems can help teams prioritize corrective actions and make informed, data-driven decisions to enhance safety protocols and operational compliance.

Following inspections, creating action plans based on findings is crucial. Setting realistic goals for compliance not only helps to drive immediate changes but also establishes long-term objectives for better performance. Regularly monitoring and reporting on improvements ensures that initiatives stay on track, ultimately leading to a safer and more efficient working environment.

Collaboration and communication post-inspection

Post-inspection, it’s vital to involve team members in reviewing findings to foster a culture of transparency and collective accountability. Implementing strategies for effective communication about results and facilitating feedback sessions will encourage collaboration towards improvement. Ensuring everyone understands the outcomes fosters a shared responsibility towards compliance and safety.

Documenting action items and establishing follow-up procedures is an essential next step. Assigning responsibilities for corrective actions enables accountability, while setting a timeline for re-inspection and updates ensures that resolutions are implemented timely.

Advanced tools for plant inspection management

Incorporating advanced tools like pdfFiller’s editing and eSigning features significantly enhances the efficiency of the inspection process. Users can easily customize forms directly within the platform, tailoring them to meet specific needs. Utilizing eSignatures accelerates the approval process, ensuring documentation is handled swiftly without unnecessary delays.

Moreover, mobile-friendly inspection solutions allow inspectors to conduct assessments efficiently on-the-go. Accessibility benefits of mobile forms mean that users can fill out inspection forms wherever they are, ensuring no detail is overlooked in real-time. Effectively leveraging these tools contributes to a more proactive and agile inspection process.

Real-world examples and case studies

Examining success stories from companies that have effectively utilized inspection forms can provide valuable insights. For instance, a prominent agricultural company improved compliance rates significantly after adopting a digital inspection form solution. The organization analyzed past inspection data, which highlighted critical areas for improvement and led to the implementation of enhanced safety measures.

Another example involves a manufacturing plant that streamlined its inspection processes by transitioning to electronic forms. The results showcased a notable reduction in errors and a higher level of compliance with safety regulations. Data analysis post-implementation revealed actionable insights that informed of risk management strategies and improved workplace health conditions.

For pdfFiller’s FAQs

Below is a list of the most common customer questions. If you can’t find an answer to your question, please don’t hesitate to reach out to us.

How do I edit plant industry - inspection in Chrome?

How do I fill out the plant industry - inspection form on my smartphone?

How do I edit plant industry - inspection on an Android device?

What is plant industry - inspection?

Who is required to file plant industry - inspection?

How to fill out plant industry - inspection?

What is the purpose of plant industry - inspection?

What information must be reported on plant industry - inspection?

pdfFiller is an end-to-end solution for managing, creating, and editing documents and forms in the cloud. Save time and hassle by preparing your tax forms online.