Get the free Dinolift DINO 135T Operating Instructions Manual page 19

Get, Create, Make and Sign dinolift dino 135t operating

Editing dinolift dino 135t operating online

Uncompromising security for your PDF editing and eSignature needs

How to fill out dinolift dino 135t operating

How to fill out dinolift dino 135t operating

Who needs dinolift dino 135t operating?

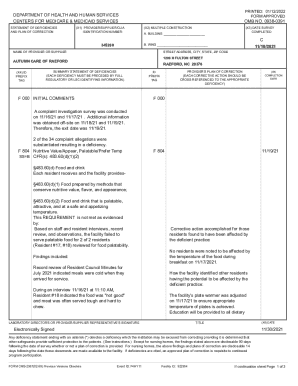

Comprehensive Guide to the Dinolift Dino 135T Operating Form

Overview of the Dinolift Dino 135T

The Dinolift Dino 135T is a versatile and robust articulated boom lift designed for both indoor and outdoor applications. Ideal for maintenance, construction, and other industry-related tasks, this machine enables operators to access heights safely. Its unique design makes it a favorite among construction companies, maintenance teams, and any business that requires elevated reaching capabilities.

With its ability to adjust reach and height, the Dino 135T is crucial for projects that require precision and safety. This lift can elevate personnel to significant heights while adhering to strict safety regulations. Industries benefit from the efficiency and reliability offered by this machine, making it a valuable asset in their operational toolbox.

Key features of the Dino 135T

The Dino 135T boasts several notable features: a maximum working height of approximately 13.5 meters, a lift capacity of up to 230 kg, and a compact design allowing for ease of maneuvering in tight spaces. The controls are user-friendly and intuitive, ensuring that both seasoned operators and beginners can navigate the operating interface with confidence.

Safety features are paramount in the Dino 135T design. The machine comes equipped with overload protection, descent alarm systems, and emergency stop functionality. These safety certifications ensure compliance with industry standards, offering peace of mind to the operator and those working nearby.

Preparing to fill out the operating form

Before operating the Dino 135T, filling out the appropriate operating form is critical. This form serves as a comprehensive guide to ensuring the machine is operated safely and according to regulations. Its significance extends beyond compliance; it facilitates effective equipment management and helps maintain perfectly documented operations, essential for audits and reviews.

Completing the operating form requires specific information. You will need to provide personal and contact details, the machine's specifications, and the operating conditions under which you'll be working. By gathering this data ahead of time, you streamline the process and enhance safety protocols.

Step-by-step instructions for completing the operating form

To complete the operating form for the Dinolift Dino 135T, start by locating the form on pdfFiller. This user-friendly platform allows you to easily find and customize any document you might need for your operations.

Once you have the form pulled up, begin with the personal information section. Accurately fill in all details required to establish proper identification, including your name, role, and contact number. Follow this by navigating to the machine information section.

Here, you'll need to enter essential specifications, such as the model number and serial number. Ensuring this information is correct is vital to maintaining accurate records. After that, it's time to detail your operational guidelines.

You should document operational conditions diligently. Consider the weather—heavy rain or winds could impact safety. Assess the job site layout as well, indicating whether it could present challenges for machine operation.

Additional notes and special instructions

Don’t hesitate to include any additional notes that could enhance operational safety or efficiency in your completed form. For instance, if there are unique challenges on-site, such as nearby pedestrian traffic or narrow pathways, make sure to highlight them in this section.

Editing the operating form

After filling out the form, you may find it necessary to edit certain details. pdfFiller offers intuitive editing features that allow real-time changes and adjustments. This functionality is particularly beneficial in collaborative environments where multiple stakeholders are involved in the process.

Taking advantage of commenting and collaboration tools fosters clear communication among all involved parties. Ensure that you routinely check for any updates regarding safety regulations, as it is crucial for compliance to incorporate current industry standards into your operating form.

Signing the operating form

Signing off on the operating form is the final step before utilizing the Dinolift Dino 135T. pdfFiller provides eSign options that enable you to electronically sign the document securely, ensuring it is legally binding and recognized.

For projects involving multiple stakeholders, follow the protocol for gathering approvals. Ensure all parties involved, including supervisors and safety officers, review and sign the operating form before the equipment is engaged to mitigate risk and enhance overall safety.

Finalizing and managing your operating form

Once the form is complete and signed, saving it in various formats is critical. pdfFiller allows you to maintain your document in the format that best suits your needs. Options include PDF, Word, and more, ensuring all parties can view it easily.

Storing the operating form in a cloud-based system simplifies document management and enhances accessibility. This ease of accessing important files fosters collaboration among team members and smooth operation management. Sharing the form is straightforward; manage permissions carefully to ensure confidential information is only seen by authorized personnel.

Troubleshooting common issues

Even with the best-laid plans, issues may still arise when filling out the operating form. Common mistakes include missing information or incorrect entries that can hinder the operation process. Double-checking your entries before submission can save you from potential delays or safety oversights.

If technical challenges arise while using pdfFiller, access help resources through the platform. Customer support offers assistance for various issues, ensuring you can resolve problems quickly and keep your operations running smoothly.

Safety and best practices

When operating the Dinolift Dino 135T, adhering to safety protocols is vital. Operators must wear appropriate personal protective equipment (PPE) and maintain awareness of their surroundings. Regular training should be conducted to ensure all personnel are familiar with safety practices and the specific functions of the machine.

Equally important are routine maintenance practices. Regular checks on hydraulic systems, brakes, and structural integrity help prolong the life of the equipment. Documenting maintenance activities and any irregularities in operation through the operating form reinforces accountability and transparency among team members, fostering a culture of safety and integrity.

For pdfFiller’s FAQs

Below is a list of the most common customer questions. If you can’t find an answer to your question, please don’t hesitate to reach out to us.

How can I send dinolift dino 135t operating for eSignature?

How do I edit dinolift dino 135t operating in Chrome?

How do I complete dinolift dino 135t operating on an Android device?

What is dinolift dino 135t operating?

Who is required to file dinolift dino 135t operating?

How to fill out dinolift dino 135t operating?

What is the purpose of dinolift dino 135t operating?

What information must be reported on dinolift dino 135t operating?

pdfFiller is an end-to-end solution for managing, creating, and editing documents and forms in the cloud. Save time and hassle by preparing your tax forms online.