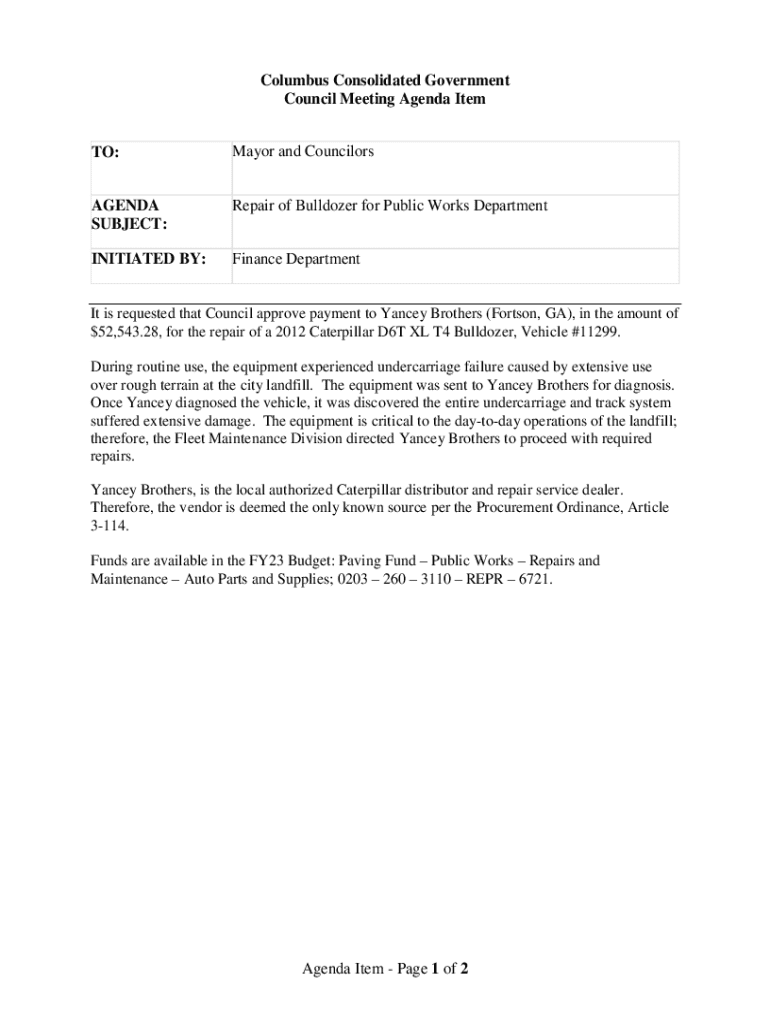

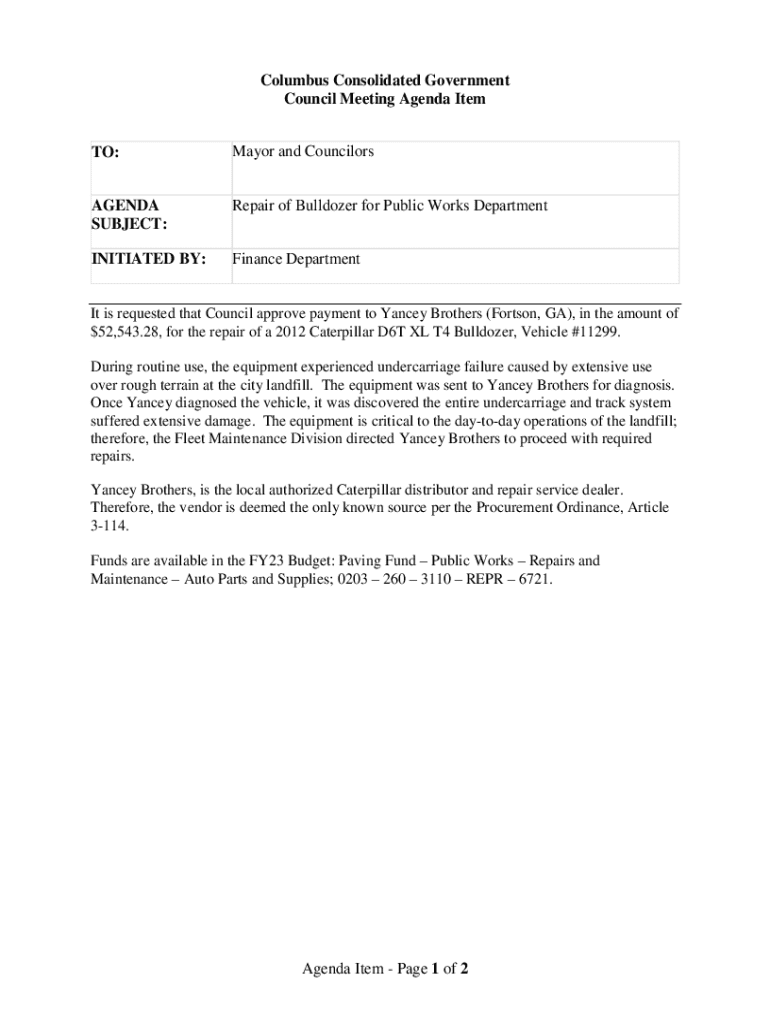

Get the free Repair of Bulldozer for Pu

Get, Create, Make and Sign repair of bulldozer for

Editing repair of bulldozer for online

Uncompromising security for your PDF editing and eSignature needs

How to fill out repair of bulldozer for

How to fill out repair of bulldozer for

Who needs repair of bulldozer for?

Repair of bulldozer: A comprehensive guide for effective maintenance

Understanding your bulldozer

A bulldozer is a formidable piece of machinery crucial to construction and earth-moving tasks. Understanding the different types of bulldozers can make a significant difference in your maintenance strategy. The two main categories are crawler and wheel bulldozers. Crawler bulldozers feature tracks that provide better traction on soft or uneven terrains, making them ideal for heavy-duty tasks. In contrast, wheel bulldozers are more suited for urban environments where speed and maneuverability are prioritized.

Each type comes with various models tailored to specific jobs. For example, Caterpillar offers models like the D6 and D8 for large earth-moving projects, while Komatsu's D31 series caters to smaller, more precise tasks. Understanding your machine's model and its specific repairs significantly enhances your performance and maintenance approach.

Common issues requiring repair

Regular use of bulldozers can result in several common issues necessitating repair. Engine problems often include overheating, sluggish performance, or unusual noises indicating a need for thorough inspection. The hydraulic system is another area where failures can surface; these can manifest as leaks, poor lifting capacities, or erratic movements. Lastly, track and undercarriage issues can lead to uneven wear, making timely repairs crucial for overall functionality and safety.

Essential tools and materials for repairs

To carry out effective repairs on your bulldozer, a set of essential tools is necessary. For basic maintenance, hand tools are crucial: wrenches for bolts, screwdrivers for panel access, and pliers for various fastening needs. For more complex repairs, power tools such as impact wrenches and drills can significantly speed up the process, reducing manual labor.

Equally important is having diagnostic tools at your disposal. Multimeters and pressure gauges aid in quickly identifying electrical and hydraulic issues. Keeping these tools organized and accessible will streamline your repair process and enable you to tackle repairs efficiently.

Materials to keep on hand

Nothing beats being prepared, especially with a bulldozer. Maintaining a stockpile of necessary materials ensures you can address issues as they arise. Engine oil and hydraulic fluid are fundamental; without them, your machinery's performance can suffer drastically. Filters, gaskets, and seals are equally essential, as these components uphold the performance of your engine and hydraulic systems.

Moreover, having replacement parts tailored to specific bulldozer models at hand reduces downtime significantly. Stocking the appropriate pieces not only prevents delays but also ensures that your repairs are done right the first time.

Step-by-step guide to common repairs

Replacing the engine oil and filter

Regular oil changes are essential to ensuring the engine runs smoothly. To replace the engine oil and filter, gather the necessary tools and materials: an oil drain pan, wrenches, a new oil filter, and the appropriate type of engine oil. First, park the bulldozer on even ground and make sure the engine is cool to avoid burns.

Next, drain the old oil into the pan. Use a wrench to remove the old oil filter, allowing any residual oil to drain away completely. Once emptied, install the new filter and secure it tightly. Finally, pour new oil into the engine, checking the levels with the dipstick to ensure you're in the optimal range.

Fixing hydraulic system leaks

Hydraulic system leaks can severely hinder your bulldozer's performance. Start by identifying the source of the leaks. Common areas include hoses and connections that might wear over time. Once you locate the leak, gather tools such as a wrench set and suitable hose replacements.

To repair a leak, safely disconnect the hoses, ensuring that hydraulic fluid does not spill. Replace them with new hoses and seals, making sure they are securely fitted. After ensuring everything is sealed, refill the hydraulic fluid and check for leaks again.

Repairing the undercarriage

The undercarriage of a bulldozer is vital for its stability and operational capability. Start with checking the track tension and alignment regularly. To replace damaged track links, gather necessary tools, including a socket wrench and jack. Remove the old links by loosening the bolts and lifting the tracks carefully.

Once old links are removed, install new ones by threading them correctly, and adjust the track tension to ensure proper fit. Regular inspections will help prevent issues before they escalate, makingsure your bulldozer remains operational without costly downtime.

Preventive maintenance practices

Mud and dirt can accumulate quickly on construction sites, so establishing a daily and weekly maintenance checklist is essential. This should include tasks like checking fluid levels, inspecting for leaks, and ensuring belts and hoses are in good condition. Regular cleaning of air filters and cooling systems is crucial to prevent overheating and maintaining optimal performance.

Seasonal maintenance also plays an important role in extending the life of your bulldozer. Before winter, ensure that the hydraulic systems are adequately protected from freezing conditions. After a summer of hard work, prioritize checking the cooling system for debris to maintain efficiency throughout the year.

Establishing a maintenance schedule

Creating a structured maintenance schedule significantly aids in the longevity of your bulldozer. Log repairs and service history to easily identify patterns in machinery performance and to preemptively address recurring issues. Whether it's through a simple notebook or a digital tool like pdfFiller, consistent logging offers a clear view of the equipment's overall health, allowing for informed decisions.

Routine inspections can highlight wear and tear before they turn into larger problems, reducing costs in the long term. By adhering to a standardized maintenance schedule, you ensure your investment remains productive and efficient.

Safety measures during repair

Safety cannot be overstated when it comes to repairing bulldozers. Wearing the right personal protective equipment (PPE) is the first step. This includes gloves, goggles, and helmets suited for heavy machinery work. Proper footwear should also protect against sharp objects often found on construction sites.

Fire safety equipment is essential, especially when working near hydraulic fluids and fuels. Ensure fire extinguishers suitable for chemical fires are accessible. Additionally, using safe lifting techniques when handling heavy parts prevents injuries, and following electrical safety protocols during diagnostics ensures that you avoid accidents related to electrical faults.

Safe handling of tools and equipment

Using tools correctly is fundamental to safety. Ensure that all tools are well-maintained, as broken or worn-out tools can cause accidents. Train all operators on the proper use of machinery and tools, emphasizing the importance of following manufacturer guidelines. Incorporating routine checks on tools adds another layer of safety, ensuring that every piece is reliable and functional.

Being aware of your surroundings and ensuring that work areas are organized greatly reduces the risk of accidents. Misplaced equipment can lead to injuries, so maintaining an orderly workspace is crucial.

When to call a professional

While many repairs can be managed on your own, recognizing when to call a professional is crucial for ensuring that more complex issues are addressed correctly. Signs that it's time to seek professional expertise include persistent issues after attempting DIY repairs. Indicators such as unusual noises, overheating, or error codes on diagnostic tools often suggest underlying problems that require a trained eye.

Finding the right repair service also takes effort. Look for professionals with a solid reputation and specific experience with bulldozers. Checking for previous customer reviews can provide insights into their reliability. Before hiring, ask relevant questions, such as turnaround times, warranty policies, and their experience with your specific model.

Choosing the right repair service

Professional maintenance not only saves time but can also prevent future complications. Ensuring the repair technician understands the mechanics of your bulldozer can lead to more effective and efficient repairs. Inquire about the use of OEM parts for replacements; this ensures that your machine retains its perfect fit and performance.

Moreover, the ability to provide maintenance logs or digital documentation through platforms like pdfFiller adds transparency to the work done. Keeping a service history is not just about accountability; it also creates a valuable resource for future maintenance and repairs.

Leveraging technology for repairs and maintenance

In today's digitized world, technology plays a pivotal role in enhancing the maintenance experience for bulldozer owners. Documenting repairs digitally streamlines the record-keeping process. Utilizing cloud-based tools such as pdfFiller to manage documentation empowers individuals and teams to access important records from anywhere.

Employing form templates for maintenance logs and service records can give you a structured way to track work done over time. And by connecting with online communities and forums dedicated to bulldozer repairs, you can leverage collective knowledge from other users and professionals, often accessing troubleshooting tips or videos demonstrating necessary repairs.

Conclusion of the repair process

Quality repairs ensure your bulldozer remains reliable and operational for years to come. It's essential to double-check all work performed, ensuring every component is secured and in the correct position. A final inspection can catch potential oversights, allowing for adjustments before fully engaging the machine in work.

Taking these steps not only underscores the importance of proper repairs but also highlights how consistent maintenance keeps your bulldozer performing. Lastly, utilizing platforms like pdfFiller to manage maintenance records keeps your documentation organized and accessible, enhancing the productivity and efficiency of your bulldozer management process.

For pdfFiller’s FAQs

Below is a list of the most common customer questions. If you can’t find an answer to your question, please don’t hesitate to reach out to us.

Can I create an eSignature for the repair of bulldozer for in Gmail?

How do I fill out the repair of bulldozer for form on my smartphone?

Can I edit repair of bulldozer for on an Android device?

What is repair of bulldozer for?

Who is required to file repair of bulldozer for?

How to fill out repair of bulldozer for?

What is the purpose of repair of bulldozer for?

What information must be reported on repair of bulldozer for?

pdfFiller is an end-to-end solution for managing, creating, and editing documents and forms in the cloud. Save time and hassle by preparing your tax forms online.