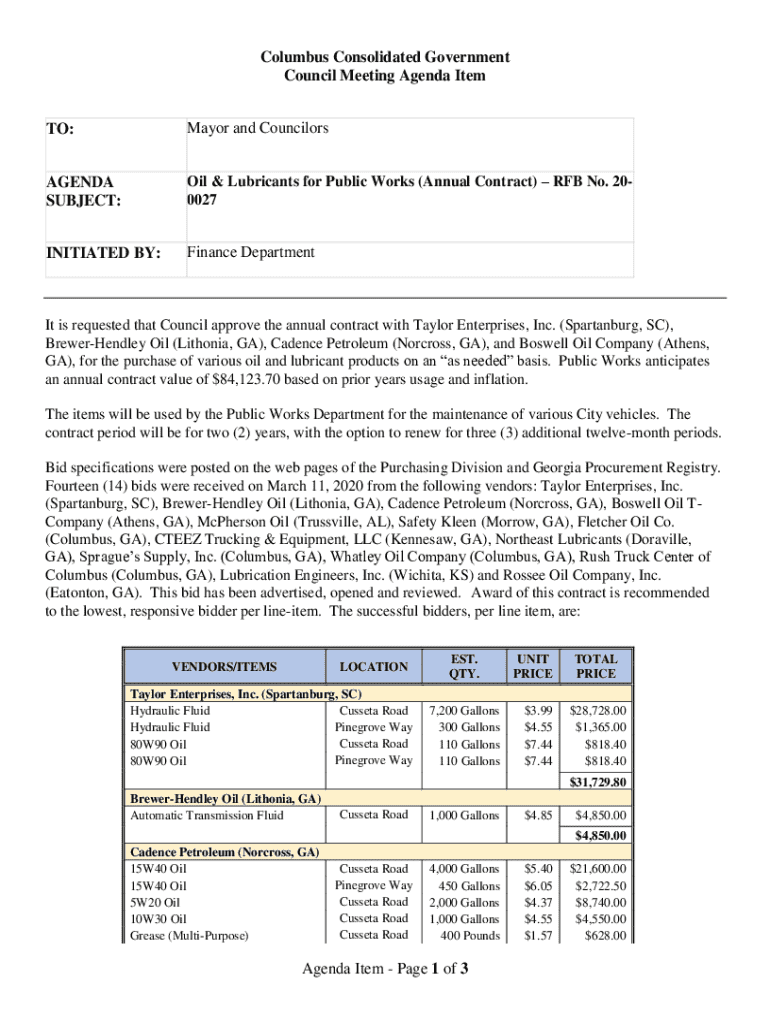

Get the free Oil & Lubricants for Public Works (Annual Contract) RFB No

Get, Create, Make and Sign oil lubricants for public

How to edit oil lubricants for public online

Uncompromising security for your PDF editing and eSignature needs

How to fill out oil lubricants for public

How to fill out oil lubricants for public

Who needs oil lubricants for public?

Oil lubricants for public form: A comprehensive guide

Understanding oil lubricants

Oil lubricants are substances designed to reduce friction between surfaces in mutual contact, thereby preventing wear and tear, overheating, and other detrimental effects on machinery. Their primary functions include lubrication, cooling, sealing, and protection against corrosion. By minimizing contact between machine components, lubricants significantly enhance operational efficiency.

In various industries, oil lubricants are indispensable. For example, the automotive sector relies on high-performance engine oils to ensure smooth operation and extend engine lifespan. Similarly, the manufacturing and aviation industries utilize specialized lubricants to maintain equipment functionality under rigorous conditions.

There are several types of oil lubricants, each suited for different applications. They generally fall into the following categories:

Essential components of oil lubricants

Oil lubricants consist of two main components: base oils and additives. Base oils are the primary component that provides the necessary lubrication properties. They can be classified into mineral, synthetic, or biodegradable oils, each offering unique characteristics that affect performance.

Additives enhance the performance of base oils and are paramount for effective lubrication. Common additive types include:

Choosing the right oil lubricant

When selecting an oil lubricant, it’s essential to consider several factors that directly affect operational efficiency, including viscosity ratings and operating temperatures. Viscosity indicates how thick or thin the oil is at specific temperatures, which in turn impacts how well it stays in place and reduces friction under high pressure.

Application-specific requirements also guide lubricant selection. Here are key considerations:

Impact of oil lubricants on performance and longevity

The efficiency of machinery operations is significantly influenced by the quality of oil lubricants used. Proper lubrication reduces wear and tear on moving parts, extending both their lifespan and functional capabilities. Lubricants work by forming a protective film over machine parts, which minimizes direct metal-to-metal contact.

Furthermore, the right lubricant can even improve fuel efficiency. Research shows a direct correlation between proper lubrication and fuel economy, especially in commercial transportation. Therefore, adhering to maintenance schedules that include regular oil changes is crucial.

Employing the proper lubricants not only safeguards machinery but also helps avert costly downtime by preventing unexpected failures.

Environmental considerations

With growing environmental concerns, the biodegradability of oil lubricants has become crucial. Industries are increasingly seeking eco-friendly options that minimize environmental impact, particularly in sensitive settings like food processing.

Proper recycling and disposal methods for used oils are essential. Not only does this practice ensure compliance with environmental regulations, but it also promotes sustainability. Some methods include recycling through specialized oil recovery facilities or participating in community disposal programs.

Certifications such as USDA BioPreferred and others guide consumers toward environmentally-friendly lubricants, assuring their safety in food-stuff environments. Awareness of industry standards fosters informed choices among manufacturers and consumers alike.

Common misconceptions and FAQs

Many individuals misunderstand the distinctions between various lubricants, particularly the differences between synthetic and mineral oils. Synthetic oils are engineered for superior performance, while mineral oils are derived from crude oil and usually cost less.

Another frequent query is regarding the necessity of defoamants in all oil lubricants. Not all applications require such additives; however, in high-speed machinery, the prevention of foam is critical to maintain effective lubrication.

Finally, the importance of dispersants cannot be overstated, as they protect engine parts from harmful sludge accumulation, prolonging engine life and performance.

How to properly store and handle oil lubricants

Proper storage of oil lubricants is essential to maintaining their integrity and performance. It is crucial to keep lubricants in a controlled environment, shielding them from excessive heat, moisture, and sunlight, which can degrade their quality over time.

Using appropriate containers is equally important. Always select containers that are specifically designed for the type of lubricant. Clearly labeling each container ensures that you can quickly identify the contents and avoid cross-contamination.

For handling, adhering to safety measures during oil transfer is crucial. Using appropriate personal protective equipment (PPE) prevents injury, while careful transfer techniques reduce spillage and waste.

Interactive tools and resources

Utilizing online calculators can greatly assist in selecting the right oil lubricant for your specific needs. These tools can take into account parameters like viscosity, environmental conditions, and specific equipment requirements.

Additionally, maintaining organized checklists for regular maintenance schedules can enhance operational efficiency. Utilizing print-friendly versions of these lists for oil changes and quality checks helps ensure no task is overlooked.

Case studies and user testimonials

Real-world applications of oil lubricants highlight their crucial role in enhancing machinery performance. For instance, companies that implemented high-quality synthetic oils documented significant reductions in downtime and maintenance costs.

Feedback from industry experts consistently emphasizes the importance of selecting the right lubricant. Insights from professionals reveal that those who prioritize lubricant management often see improvements in operational productivity and mechanical reliability.

Latest innovations in oil lubricants

Emerging technologies continue to reshape the oil lubricant landscape. Innovations in formulations aim to enhance efficiency and environmental compatibility, such as the development of new biodegradable oils that suit food-grade lubrication applications.

Looking ahead, industry trends suggest that tightening environmental regulations will push for further advancements in eco-friendly lubricants. This shift may not only involve the development of novel products but also a re-evaluation of existing manufacturing practices to reduce their environmental footprint.

For pdfFiller’s FAQs

Below is a list of the most common customer questions. If you can’t find an answer to your question, please don’t hesitate to reach out to us.

How can I edit oil lubricants for public from Google Drive?

How do I edit oil lubricants for public in Chrome?

Can I create an electronic signature for signing my oil lubricants for public in Gmail?

What is oil lubricants for public?

Who is required to file oil lubricants for public?

How to fill out oil lubricants for public?

What is the purpose of oil lubricants for public?

What information must be reported on oil lubricants for public?

pdfFiller is an end-to-end solution for managing, creating, and editing documents and forms in the cloud. Save time and hassle by preparing your tax forms online.