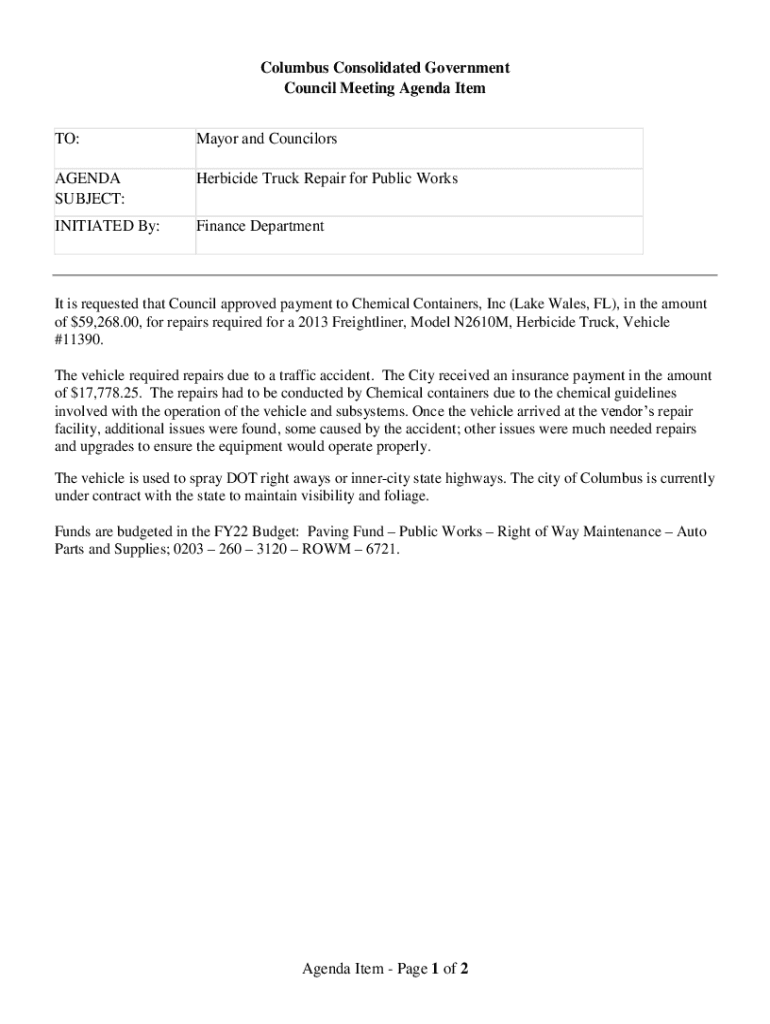

Get the free Herbicide Truck Repair for Public Works

Get, Create, Make and Sign herbicide truck repair for

Editing herbicide truck repair for online

Uncompromising security for your PDF editing and eSignature needs

How to fill out herbicide truck repair for

How to fill out herbicide truck repair for

Who needs herbicide truck repair for?

Herbicide Truck Repair for Form: A Comprehensive Guide

Understanding the importance of herbicide truck maintenance

Herbicide trucks play a vital role in agricultural efficiency, enabling farmers and applicators to apply herbicides effectively across vast fields. These trucks are specifically designed to handle the unique demands of transporting and applying chemicals used to control weeds, thus safeguarding crops such as corn and soybeans. Proper maintenance of these vehicles ensures that they deliver herbicides safely and efficiently, which is crucial for managing large agricultural operations.

Neglecting maintenance can lead to mechanical failures that not only hinder productivity but can also pose risks to the environment and surrounding communities. Periodic checks and timely repairs ensure that the sprayers function optimally and minimize herbicide residues, keeping compliance with agricultural regulations. This underlines why proactive maintenance is not merely an option but a necessity for anyone relying on herbicide application.

Common issues faced by herbicide trucks

Herbicide trucks often face a range of mechanical and operational problems. Some of the most common issues include hydraulic leaks, clogged nozzles, and faulty pumps. These problems can significantly decrease the effectiveness of herbicide application and may even damage crops if not addressed promptly. Recognizing the signs that your herbicide truck needs repairs, such as irregular spraying patterns or unusual noises during operation, is crucial.

Failing to maintain these vehicles can lead to costly downtime during critical application seasons. For example, if a pump fails on the eve of a scheduled herbicide application, it can delay field treatments, jeopardizing crop yields. Thus, understanding and addressing common issues promptly not only enhances operational efficiency but also extends the life of the herbicide truck.

Preparing for herbicide truck repairs

Before embarking on herbicide truck repairs, gathering the necessary tools and materials is essential. Key tools include wrenches, pliers, and various fittings for hoses along with replacement parts like pumps and seals. Preparing a clean workspace that is free of chemicals greatly reduces the risk of accidents and ensures that the repairs can be conducted safely.

Monitor safety precautions such as wearing gloves and goggles when handling herbicides and ensure that there is proper ventilation if repairs are conducted indoors. It's also important to consult the manufacturer's guidelines for specific recommendations related to your herbicide truck’s model before initiating repairs. Familiarizing yourself with these details can streamline the repair process and prevent unnecessary errors.

Step-by-step repair process

Identifying and diagnosing problems

Systematic assessment is critical in diagnosing problems with your herbicide truck. Start by inspecting both the mechanical and hydraulic systems. This assessment should include checking for leaks in hoses and connections, ensuring proper functionality in the pump, and examining the overall condition of the sprayer application system.

For instance, if you notice uneven application rates, the problem may stem from a clogged nozzle or a malfunctioning pump. Regular inspection helps you catch potential issues early before they escalate into more significant and expensive repairs.

Common repair procedures

Addressing leaks in hoses and connections involves thoroughly examining the entire hydraulic system and tightening or replacing any defective parts. Repairing or replacing faulty pumps is often necessary if performance problems occur or if you observe low pressure during application. Moreover, electrical issues can arise from worn-out wiring or corroded terminals, requiring a skilled electrician to ensure safe repairs.

Cleaning and maintenance practices

Keeping your herbicide application equipment clean is vital. Implementing best practices includes flushing out hoses and sprayers with water after each use to eliminate any residues that could harden and affect performance. Additionally, establishing a routine maintenance schedule can help in tracking the life expectancy of parts and ensuring that inspections and repairs are carried out on time.

Using pdfFiller for documentation

Documenting repairs and maintenance is crucial for tracking the performance and longevity of your herbicide truck. pdfFiller provides an efficient solution for accessing and filling out repair forms online. With this tool, managers can keep detailed records of maintenance schedules and repairs, making it easier to monitor when service is due or if recurring issues arise.

The benefits of using such an online tool vs. traditional paper forms include greater accessibility, streamlined collaboration, and the ability to easily edit and customize repair work orders and invoices. This can significantly save time and reduce paperwork errors, thereby enhancing overall operational efficiency.

Interactive tools for effective management

Utilizing pdfFiller’s collaborative features is paramount for teams managing herbicide truck repairs. Teams can track repairs collectively using shared documents, ensuring that everyone, including applicators and technicians, is on the same page regarding the status of repairs or upcoming maintenance needs.

The ability to easily share documents with team members or repair technicians fosters transparent communication. Furthermore, employing eSignature capabilities can expedite approval processes for repairs, ensuring that maintenance activities don't face unnecessary delays while waiting for sign-offs.

Case studies: successful herbicide truck repairs

Real-world examples showcase the effectiveness of timely repairs. A farmer in Iowa experienced a significant reduction in herbicide application errors after implementing a maintenance schedule based on detailed documentation from pdfFiller. By identifying and addressing mechanical issues promptly, he avoided a season's worth of crop damage, saving thousands in potential losses.

Similarly, a cooperative managing multiple herbicide trucks adopted a collaborative repair tracking system using pdfFiller. This led to improved communication among team members, reduced downtime, and overall enhanced productivity. The lessons learned from these cases reveal that effective maintenance strategies and documentation significantly contribute to the success of agricultural operations.

Future-proofing your herbicide truck operations

Investing in high-quality parts and maintenance solutions is essential for future-proofing herbicide truck operations. Choosing reliable suppliers for replacement components helps ensure that the parts meet manufacturers’ standards, reducing the risk of breakdowns.

Exploring technology trends, like advanced diagnostic tools and automated maintenance reminders, can improve operational efficiency. Implementing a long-term maintenance strategy, including regular training for staff on best practices and safety protocols, will reduce costly breakdowns and guarantee that herbicide application remains effective and compliant.

FAQs on herbicide truck repair

Common questions regarding herbicide truck maintenance often include inquiries about the periodicity of inspections and how often to replace hoses. A general guideline is to inspect all major components regularly, at least every season, or more frequently during peak operation times to ensure optimal function.

Troubleshooting on the go can sometimes be managed by checking the pump's output pressure and nozzle performance. Always consult your operational manual for specific troubleshooting tips tailored to your model. Numerous resources exist for further learning to help users and managers maintain their herbicide trucks effectively.

The cost of inaction

Neglecting to repair herbicide trucks can have significant financial implications. A small issue, such as a leak in hoses, can escalate into a costly repair if not addressed early, potentially leading to complete truck failure. This can result in lost time and repairs that can quickly add up to thousands of dollars.

In contrast, timely maintenance can provide significant savings by optimizing performance and reducing downtime. Implementing a proactive maintenance approach not only mitigates immediate repair costs but also ensures that herbicide application is consistent, effective, and safe for crop production.

For pdfFiller’s FAQs

Below is a list of the most common customer questions. If you can’t find an answer to your question, please don’t hesitate to reach out to us.

How can I send herbicide truck repair for to be eSigned by others?

How do I fill out the herbicide truck repair for form on my smartphone?

How can I fill out herbicide truck repair for on an iOS device?

What is herbicide truck repair for?

Who is required to file herbicide truck repair for?

How to fill out herbicide truck repair for?

What is the purpose of herbicide truck repair for?

What information must be reported on herbicide truck repair for?

pdfFiller is an end-to-end solution for managing, creating, and editing documents and forms in the cloud. Save time and hassle by preparing your tax forms online.