What is Master Production Schedule?

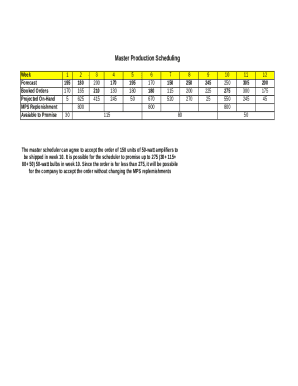

The Master Production Schedule (MPS) is a plan that outlines the production quantities and timing for specific products. It serves as a crucial tool for production planning and helps businesses meet customer demands efficiently.

What are the types of Master Production Schedule?

There are two main types of Master Production Schedules: the Material Requirement Planning (MRP) based approach and the Sales and Operations Planning (S&OP) based approach.

Material Requirement Planning (MRP) based approach

Sales and Operations Planning (S&OP) based approach

How to complete Master Production Schedule

Completing a Master Production Schedule involves several key steps:

01

Evaluate current inventory levels and production capabilities

02

Assess customer demand and market trends

03

Define production quantities and timelines

04

Coordinate with suppliers and other departments

05

Review and adjust the schedule regularly to optimize production efficiency

pdfFiller empowers users to create, edit, and share documents online. Offering unlimited fillable templates and powerful editing tools, pdfFiller is the only PDF editor users need to get their documents done.

Video Tutorial How to Fill Out Master Production Schedule

Thousands of positive reviews can’t be wrong

Read more or give pdfFiller a try to experience the benefits for yourself

Questions & answers

What is the difference between MRP and master production schedule?

In short, an MRP, or Materials Requirements Planning, is used to determine how many materials to order for a particular item, while an MPS, or Master Production Schedule, is used to determine when the materials will be used to produce an item.

What is MRP production schedule?

What Is MRP Scheduling? Material requirements planning (MRP) is an inventory and purchasing planning tool that calculates the amount of dependent demand items such as raw materials, components and subassemblies needed to produce a finished good ing to its demand-driven production schedule.

What is the difference between MRP production planning and scheduling?

The main difference is that production planning works with orders planned by the MRP and fixed orders planned by the MPS outside the cumulative lead time window, while scheduling works by converting the orders planned by the MRP into fixed planned orders with the MPS and, finally, in work orders once they enter the

What is master schedule in MRP?

The master production schedule defines the anticipated build schedule for critical items. An effective master production schedule provides the basis for order promising and links the aggregate production plan to manufacturing by specific items, dates, and quantities.

What is the difference between master schedule and master production schedule?

A master production schedule (MPS) is the overall plan to assess the production of your finished goods. Your master schedule details how much needs to be produced within a certain period.

What is a master production schedule simple example?

As an example, say a shampoo manufacturer gets a big order. Their MRP tool looks at all the ingredients that go into making shampoo — such as fragrance, colors and surfactants — and tells the user how much of each ingredient is needed, as well as when they need to buy those materials to complete the order on time.

Related templates