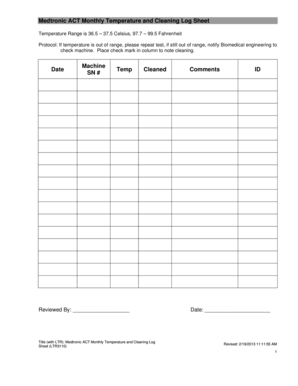

ISU Ice Machine Cleaning and Sanitizing free printable template

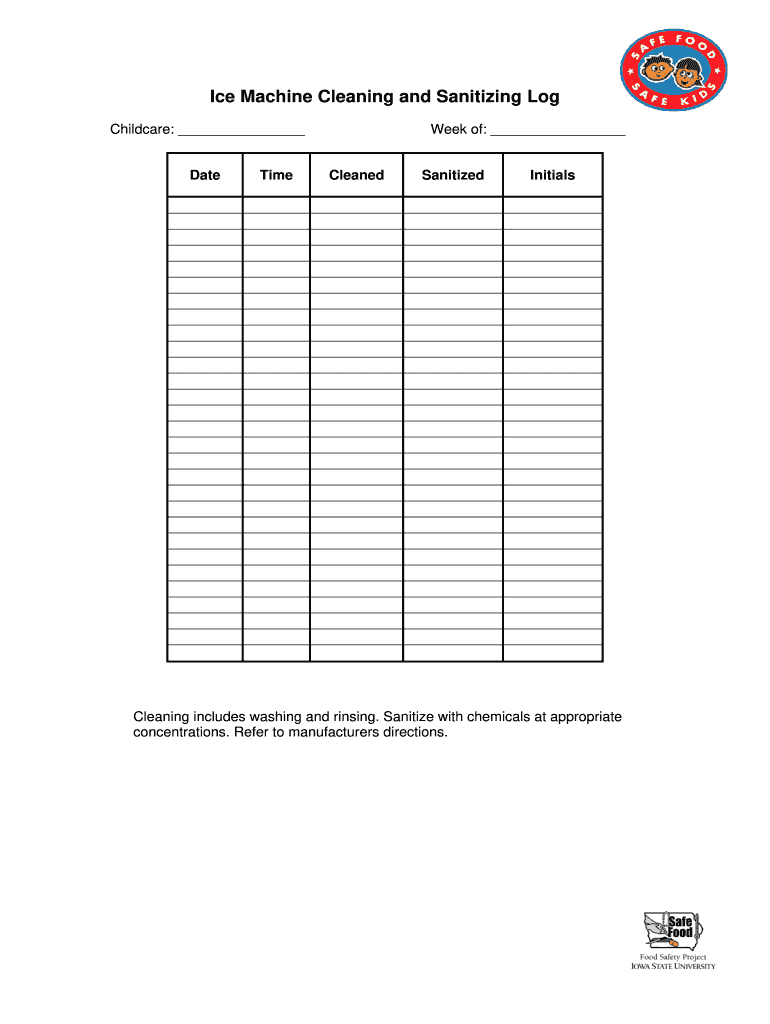

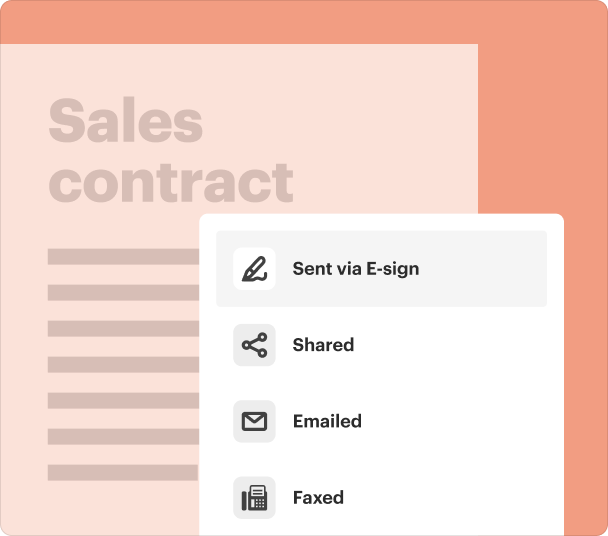

Fill out, sign, and share forms from a single PDF platform

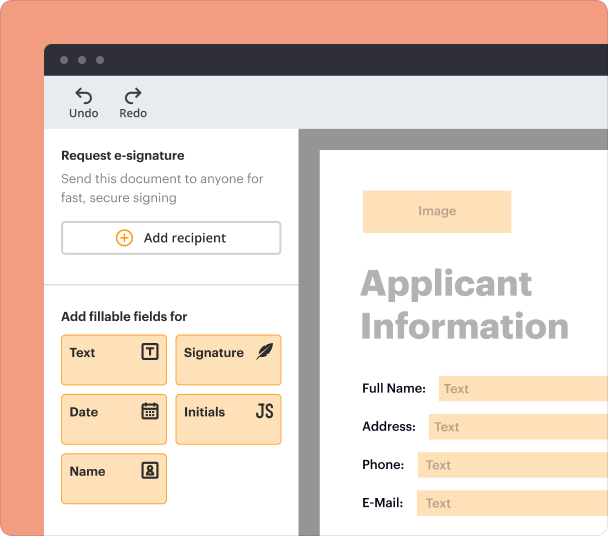

Edit and sign in one place

Create professional forms

Simplify data collection

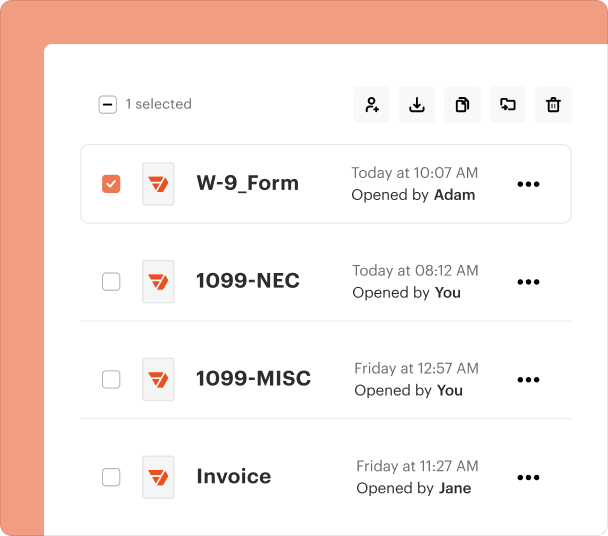

Manage forms centrally

Why pdfFiller is the best tool for your documents and forms

End-to-end document management

Accessible from anywhere

Secure and compliant

How to fill out an ISU ice machine cleaning form

Understanding the process of filling out an ISU ice machine cleaning form is crucial for maintaining safety standards and compliance within ice facilities.

-

You can access the ISU ice machine cleaning log from pdfFiller. This convenient platform allows users to fill out, edit, and save the document securely.

-

Ensure you understand the specific cleaning requirements and protocols outlined by the ISU to comply with industry regulations.

What are the ISU ice machine cleaning requirements?

Industry regulations dictate that ice machines must be kept clean to prevent contamination. Regular cleaning and sanitizing procedures are vital for health and safety, ensuring that the ice produced is safe for consumption and complies with health standards.

-

Regular cleaning helps mitigate the risks of pathogens and ensures compliance with local health regulations.

-

Failing to properly sanitize ice machines can lead to health risks, operational shutdowns, and potential legal issues.

How do utilize the ice machine cleaning and sanitizing log?

To effectively manage ice machine cleanliness, utilizing the ice machine cleaning log is essential. The log serves as a documented guarantee that cleaning routines are performed consistently.

-

The cleaning log can be easily navigated on pdfFiller, allowing for quick access and downloads.

-

Each section must be meticulously completed to ensure accountability and thoroughness in cleaning activities.

What key sections are in the ice machine cleaning log?

Understanding the various sections of the cleaning log will aid in accurate documentation and compliance tracking.

-

This section tracks which team members are responsible for the cleaning tasks.

-

Accurate logging of cleaning schedules promotes accountability and routine adherence.

-

This section describes the methods used, ensuring standard operating procedures are followed.

-

Initials provide a clear accountability measure, ensuring all tasks are verifiable.

What sanitation procedures and chemical use guidelines should follow?

Utilizing safe and effective cleaning chemicals is paramount in ice machine maintenance. Select products that meet industry standards for sanitization.

-

Opt for environmentally-friendly cleaning agents to comply with sustainability initiatives.

-

Understanding the correct concentrations of cleaning solutions is vital to ensure effectiveness without harming equipment.

-

Following best practices in sanitation will ensure compliance and promote the safety of users.

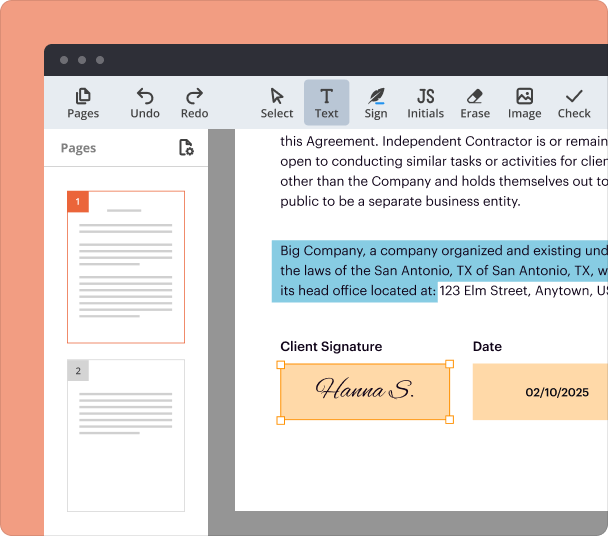

What interactive features does pdfFiller offer for document management?

pdfFiller's interactive tools simplify document management, allowing users to efficiently navigate their forms.

-

Access documents from anywhere, ensuring convenience and flexibility.

-

Enhance team efficiency with features that allow multiple users to collaborate in real-time.

-

Simplify approvals and maintain compliance using the built-in eSignature capabilities.

What are the compliance and best practices in ice facilities?

Adopting compliance practices is essential for the proper management of ice facilities. Understanding local regulations helps ensure that cleaning protocols are effective.

-

Incorporate ISU endorsed sustainability practices to promote environmental responsibility.

-

Ensure that your cleaning methods are aligned with current health regulations and technological advancements.

-

Continuously educate staff on hygiene standards and compliance measures to maintain a high level of safety.

How do manage and store cleaning documentation?

Organizing your cleaning logs in pdfFiller aids in efficient documentation management. Proper storage ensures easy retrieval when needed.

-

Use structured folders within pdfFiller for better document management.

-

Implement systematic archival methods for easy access to historical cleaning records.

-

Maintaining comprehensive records is crucial during inspections and audits for compliance.

What are common concerns in ice machine maintenance?

Addressing common issues related to ice machine maintenance proactively can prevent failures and enhance safety.

-

Neglecting cleaning can lead to malfunctioning machines or substandard ice quality.

-

Develop strategic methods for staff to report cleaning discrepancies and maintain high standards.

Frequently Asked Questions about ice machine cleaning schedule form

What is the purpose of the ISU ice machine cleaning form?

The purpose of the ISU ice machine cleaning form is to document cleaning activities and ensure compliance with health and safety regulations. It serves as a tool for accountability and tracking cleaning schedules.

How often should ice machines be cleaned?

Ice machines should ideally be cleaned on a regular basis according to the manufacturer's guidelines and local health regulations. This typically involves daily maintenance and more thorough cleaning weekly or biweekly.

Can I use any cleaning chemical for ice machines?

It's important to use only industry-approved cleaning chemicals specifically designed for food-grade equipment such as ice machines. This prevents contamination and ensures safe ice production.

What are the best practices for filling out the cleaning log?

Best practices include filling out the log with accurate dates and initials, ensuring clarity in the cleaning methods used, and consistently reviewing the logs for compliance and completeness. Accurate documentation supports quality assurance.

How can pdfFiller help with form management?

pdfFiller simplifies form management through features such as cloud-based access, collaborative tools for team engagement, and eSignature options for smoother approval processes. These functionalities enhance efficiency and facilitate compliance.

pdfFiller scores top ratings on review platforms