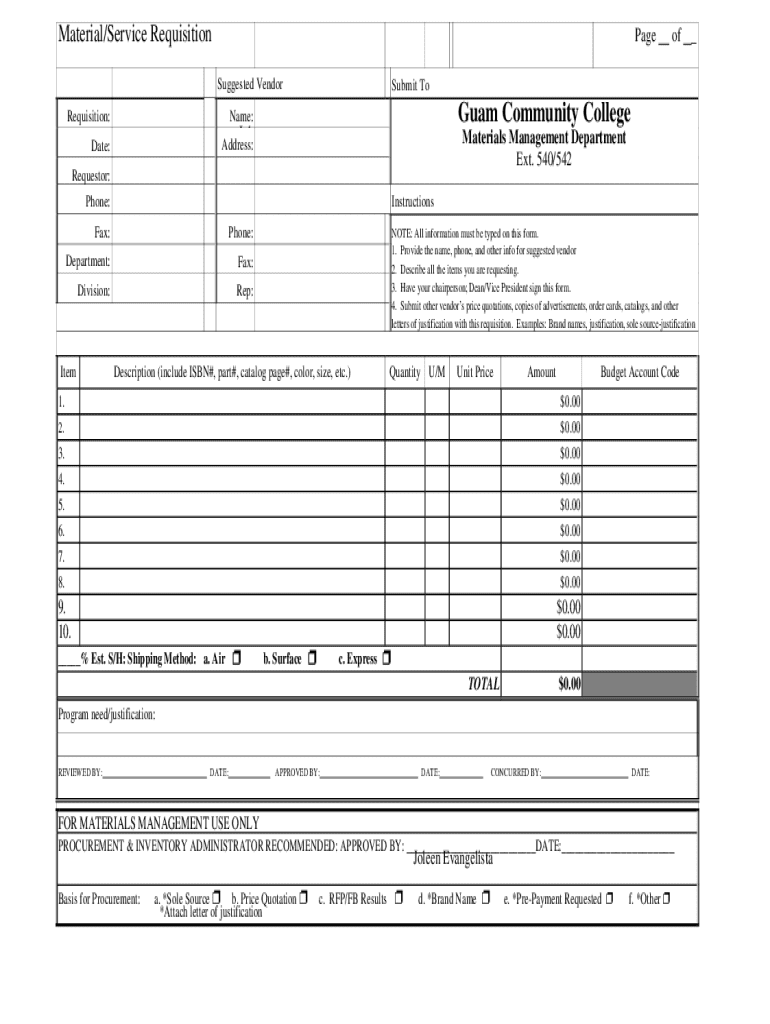

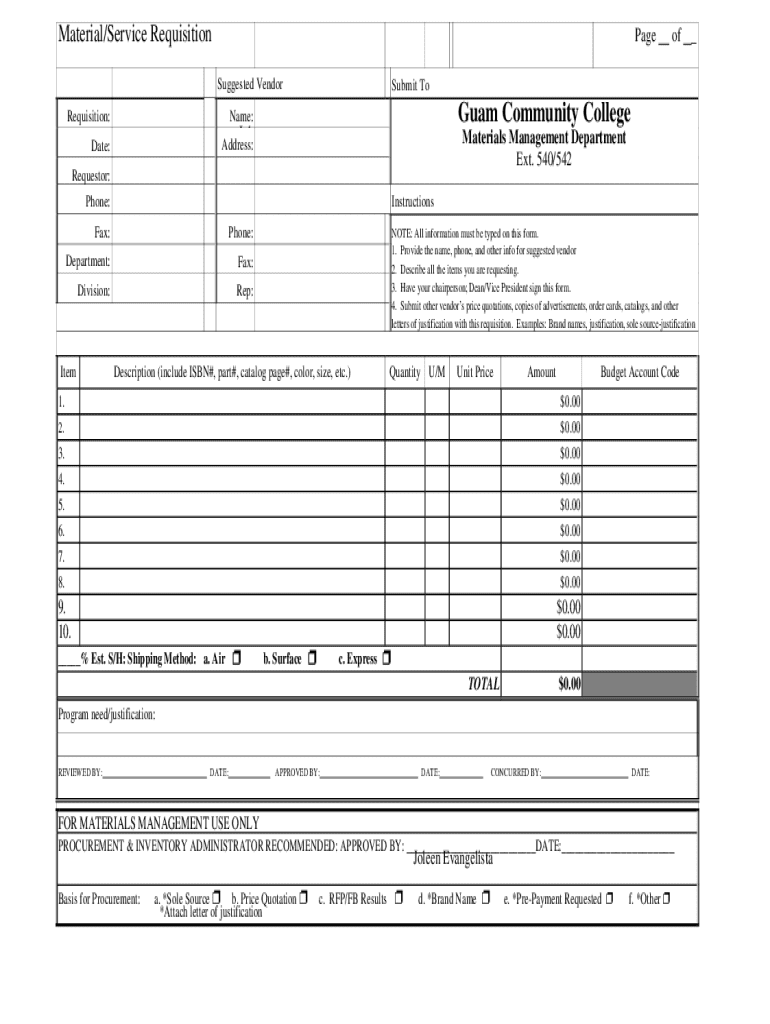

Get the free Material/service Requisition - ifs guamcc

Get, Create, Make and Sign materialservice requisition - ifs

Editing materialservice requisition - ifs online

Uncompromising security for your PDF editing and eSignature needs

How to fill out materialservice requisition - ifs

How to fill out materialservice requisition

Who needs materialservice requisition?

Material service requisition - IFS form: A Comprehensive Guide

Understanding the material service requisition

A Material Service Requisition (MSR) is a critical document used for requesting materials or services in the IFS (Industrial and Financial Systems) environment. This requisition serves as the backbone of inventory and supply chain management, allowing organizations to efficiently track their material needs and streamline the procurement process. By formalizing requests in a structured format, the MSR helps ensure that the necessary resources are acquired in a timely manner, thus minimizing delays in production and service delivery.

In the context of IFS, which is designed to enhance business processes across various sectors, the MSR plays an instrumental role in maintaining operational efficiency. It not only records item specifications but also integrates with inventory systems to update stock levels in real time. This integration is pivotal for businesses relying on just-in-time inventory practices, as it reduces the likelihood of surplus or shortages of essential materials.

Key features of the IFS form for material service requisition

The IFS form for Material Service Requisition is equipped with several features that set it apart and enhance its usability in optimizing procurement processes. Most notably, it offers comprehensive data collection capabilities, ensuring that all necessary information is captured efficiently. Users are required to fill in various fields such as requisition header details, condition code, and specific requisition lines to accurately describe their material needs.

Accessibility is another critical feature of the IFS MSR form, as it is cloud-based. This enables users to access and submit requisitions from anywhere, at any time, using any device with internet connectivity. The user-friendly interface further adds to the experience, as it simplifies navigation and encourages quick and efficient form completion. Moreover, seamless integration with existing workflows ensures that requisitions flow smoothly through approval processes without causing interruptions in day-to-day operations.

Prerequisites for using the IFS material service requisition form

Before utilizing the IFS Material Service Requisition form, certain prerequisites must be fulfilled to ensure a smooth process. Firstly, users must have the required permissions to access and submit requisitions. This typically involves having designated roles within the IFS system that allow them to initiate and manage requisitions effectively.

Additionally, having the necessary documentation and data ready before initiating a requisition is crucial. This includes knowing the specific parts required, their supply codes, and their corresponding inventory part details. Depending on the organization's infrastructure, it might also be necessary to set up specific software tools or integrate additional applications to support the MSR process seamlessly.

Step-by-step guide to filling out the IFS material service requisition form

Filling out the IFS Material Service Requisition form can be broken down into several clear steps, making it easier for users to follow and complete accurately. The first step involves accessing the form by navigating through the IFS platform. Users should log into their accounts, locate the requisition module, and select the appropriate form.

Once the form is accessed, users will proceed to enter the required information. This includes completing fields associated with the requisition header and specifying the requisition lines. It’s essential to organize the entries accurately to avoid errors. Here are key areas to focus on:

After entering the necessary information, the next step is uploading supporting documents. This could include quotes from suppliers or specifications for custom parts. Users should adhere to best practices for file formats, ensuring documents are clear and recognizable by the system. After uploading, the final step involves reviewing and submitting the requisition. Double-checking entries ensures accuracy in the requisition, preventing delays in the approval process.

System effects and workflow integration

The impact of submitting a Material Service Requisition through the IFS platform extends beyond initial data entry; it significantly affects inventory management within the organization. When a requisition is submitted, the inventory system is updated, reflecting changes in stock levels for the requested materials. This automated adjustment helps in maintaining an accurate view of availability and safeguards against stock discrepancies.

Notifications and communications associated with the requisition exist as part of the workflow integration. After submission, relevant stakeholders receive updates regarding the status of the requisition. Through the IFS system, users can track their requisitions, providing visibility into approval timelines and any pending actions required by other team members. This organized approach helps reduce miscommunication and fosters accountability across departments.

Common pitfalls to avoid

While navigating the IFS Material Service Requisition process can be straightforward, several common pitfalls can hinder progress. A frequent mistake involves overlooking necessary fields in the form. Incomplete requisition lines can result in rejection or delays in processing, so thorough attention to each field is essential.

Delays in the approval process can occur due to miscommunication with stakeholders involved in the requisition review. It's important to align expectations between requisitioners and approvers. Additionally, failing to provide appropriate supporting documents can escalate the likelihood of complications. Ensuring that all required documents are attached enhances the chances of obtaining a swift approval.

Best practices for optimizing the material service requisition process

To optimize the Material Service Requisition process using IFS, organizations can adopt several best practices. Streamlining data entry procedures by creating templates or using preset options can significantly enhance efficiency. This cut down on repetitive manual entry and reduces potential errors associated with data input, allowing team members to focus on reviewing and approving requisitions more judiciously.

Another effective method involves utilizing collaborative tools for team submissions. Encouraging employees to work together using shared platforms can facilitate communication and prompt resolution of issues related to requisition details. Regularly reviewing and revising the requisition process helps identify bottlenecks and areas for improvement. Educating team members on proper form completion ensures adherence to best practices, while leveraging analytics within the IFS system empowers users to make informed decisions based on prior requisition data.

Related forms and windows in the IFS system

Within the IFS system, various forms and windows support the material service requisition process and overall material management. Understanding connected forms, such as the Purchase Order form and Inventory Management windows, is essential for a holistic view of the procurement landscape. These interconnected systems provide users with the ability to transition smoothly from requisition to order and facilitate tracking materials through every step of the acquisition process.

Navigating through these related windows enhances user experience, particularly by creating seamless links between requisition statuses and inventory availability. Identifying dependencies and integrations between forms allows for comprehensive data management, ultimately helping organizations optimize resource acquisition while minimizing costs and risks associated with stock shortages.

FAQs about the IFS material service requisition form

As users engage with the IFS Material Service Requisition form, several questions frequently arise. One common inquiry is what to do if they encounter issues during the form submission process. Typically, reaching out to the IFS support team or a designated internal IT contact can resolve these problems. Additionally, many organizations have established step-by-step troubleshooting guidelines that can assist users in overcoming hurdles.

Another frequently asked question pertains to modifying a submitted requisition. If changes are necessary after submission, users should review the guidelines set by their specific organization, as procedures may vary. Understanding typical approval timelines is also critical for users eager to track their requisitions, as varying factors can influence processing time. Lastly, users often express interest in how electronic signing is incorporated into the requisition process, particularly regarding compliance and security protocols.

Real-world applications of the material service requisition

Real-world applications of the Material Service Requisition form within the IFS environment highlight its significance across various industries. From manufacturing to healthcare, the requisition process has enabled organizations to effectively manage inventory and service needs. For instance, a manufacturing firm might utilize the MSR to request specific parts for machinery, ensuring minimal downtime and maintaining operational efficiency. Cross-department collaborations often enhance this process, as materials traverse various functions based on need.

Case studies showcase how adopting the IFS MSR has transformed procurement cycles in organizations. An instance may involve a healthcare provider that consistently requires medical supplies; employing the MSR enables them to maintain necessary inventory levels, fulfilling regulatory requirements while delivering quality patient care. These tangible benefits affirm the importance of an organized, actionable requisition system that fosters transparency and accountability within the procurement process.

For pdfFiller’s FAQs

Below is a list of the most common customer questions. If you can’t find an answer to your question, please don’t hesitate to reach out to us.

Where do I find materialservice requisition - ifs?

How do I make edits in materialservice requisition - ifs without leaving Chrome?

How do I complete materialservice requisition - ifs on an Android device?

What is materialservice requisition?

Who is required to file materialservice requisition?

How to fill out materialservice requisition?

What is the purpose of materialservice requisition?

What information must be reported on materialservice requisition?

pdfFiller is an end-to-end solution for managing, creating, and editing documents and forms in the cloud. Save time and hassle by preparing your tax forms online.