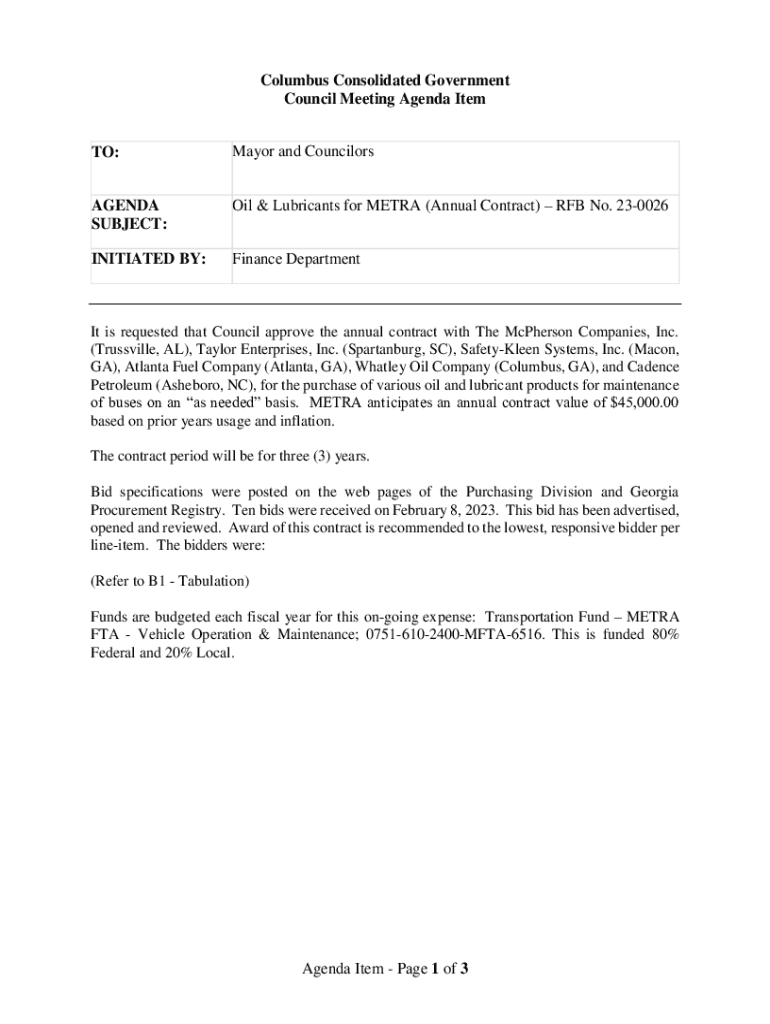

Get the free Oil & Lubricants for METRA (Annual Contract) RFB No

Get, Create, Make and Sign oil lubricants for metra

How to edit oil lubricants for metra online

Uncompromising security for your PDF editing and eSignature needs

How to fill out oil lubricants for metra

How to fill out oil lubricants for metra

Who needs oil lubricants for metra?

Oil lubricants for Metra forms: A comprehensive guide

Understanding oil lubricants

Oil lubricants are substances that minimize friction between surfaces in mutual contact, thus reducing the wear and tear of machinery. Their primary purpose is to enhance the efficiency of machinery by ensuring smooth operation. There are several types of oil lubricants, including mineral oils, synthetic oils, and biodegradable oils, each tailored to specific applications and environmental conditions.

The importance of oil lubricants in industrial applications cannot be overstated. They play a crucial role in machinery performance, helping to prevent overheating and reducing energy consumption. Properly selected and maintained lubricants can significantly prolong equipment longevity and minimize maintenance costs.

Overview of Metra forms

Metra forms refer to a type of modular formwork system extensively used in construction and manufacturing. These forms facilitate the creation of concrete structures with precision, especially beneficial in residential and commercial projects. Industries that commonly utilize Metra forms include construction, civil engineering, and even specialized manufacturing sectors that require durable and efficient casting methods.

Proper lubrication has a significant impact on the performance of Metra applications. It helps to prevent issues such as corrosion and wear on the form surfaces, which can arise when forming materials interact without lubrication. Oil lubricants reduce these risks, enhancing the overall effectiveness and efficiency of the formwork systems.

Selecting the right oil lubricant for Metra forms

When selecting oil lubricants for Metra forms, various factors come into play. Viscosity requirements are essential; thicker oils provide better adhesion and protection but may need more energy to apply. Temperature considerations are also crucial, as extreme heat can thin oils too much, reducing their protective qualities. Additionally, environmental regulations could dictate the type of lubricants permitted in specific applications.

There are two major categories of oil lubricants: synthetic and mineral oils. Synthetic oils generally offer superior performance, including better thermal stability and reduced deposit formation. Additives are also essential, as they can provide additional benefits like rust protection, enhanced oxidation stability, and improved film strength. It's advisable to assess different oil lubricants based on these criteria.

Some top-rated lubricants for Metra forms include products from leading manufacturers known for their quality. It’s beneficial to perform a comparative analysis based on features like performance under stress, packaging, and cost-effectiveness to ensure you choose a suitable product.

Application process for oil lubricants

The application of oil lubricants requires thorough preparation and execution to ensure maximum effectiveness. Here’s a step-by-step guide to applying oil lubricant to Metra forms:

Maintenance and management of lubrication

Maintaining lubricated Metra forms significantly influences operational efficiency. Regular inspection schedules should be established to check the health of lubricated components and ensure optimal performance. Regular checks enable early detection of lubrication failures, ensuring timely corrective actions.

Managing inventory of oil lubricants is vital for seamless operations. Track lubricant usage and expiration dates to avoid issues related to supply shortages or using expired products. Establishing a budget for lubricant costs ensures all necessary products are procured without impacting operations.

When handling oil lubricants, adhering to health and safety guidelines is non-negotiable. Proper PPE (Personal Protective Equipment) should be utilized, and lubricants must be stored in compliance with safety standards to prevent accidents and environmental contamination.

Troubleshooting common issues

Identifying problems related to lubrication in Metra forms is essential for maintaining performance levels. Common signs of lubrication failure include unusual noises, overheating, or excess wear on equipment. Ignoring these symptoms can lead to severe operational disruptions.

Potential causes for lubrication failure may range from using the wrong type of lubricant to insufficient application. Quick fixes might involve reapplying the lubricant or switching to a different product, while long-term solutions could require a systematic review of lubrication practices.

If problems persist despite corrective actions, consulting with lubrication professionals can provide insights and solutions tailored to specific operational settings.

Interactive tools and resources

Utilizing interactive platforms can greatly enhance the management of lubrication needs. For instance, pdfFiller offers features that allow users to create and manage lubrication schedules efficiently. This platform promotes collaboration among teams responsible for lubrication tasks, ensuring accountability and keeping everyone informed.

Customizable templates for lubrication management can be developed using pdfFiller, enabling users to track usage and schedule maintenance effortlessly. Integrating lubricant tracking with Metra forms can streamline operations, helping maintain compliance with health and safety regulations while optimizing workflow.

Case studies

Success stories provide valuable insights into the impact of proper lubrication implementation. Numerous companies have reported improved efficiency and reduced maintenance costs by selecting the right oil lubricants for their Metra forms. One such instance involved a major construction firm that switched to synthetic lubricants, resulting in a 30% decrease in machinery downtime.

These real-world examples illustrate that following best practices not only enhances operational efficiency but also promotes a proactive approach to maintenance. Lessons learned from these implementations can provide critical insights for other businesses seeking to improve their lubrication strategies.

Advanced techniques in lubrication

Emerging technologies in lubricant application are transforming how lubrication is approached in industrial settings. Innovative techniques such as automated lubrication systems and predictive maintenance leveraging data analysis are becoming more commonplace. These advanced techniques not only enhance consistency in lubrication delivery but also minimize human error.

Predictive maintenance is particularly noteworthy; by analyzing operational data, companies can anticipate lubrication needs, effectively reducing costs and extending the lifespan of their equipment. Implementing these advanced approaches can ensure optimal performance and reliability in Metra form applications.

Conclusion of key insights

In conclusion, the pivotal role of oil lubricants for Metra forms cannot be overstated. From selection and application to maintenance and innovative advancements, each aspect significantly contributes to the overall operational efficiency and longevity of equipment. By following best practices in lubrication management, organizations can realize substantial improvements in performance while reducing costs and extending machinery life. As we move forward, embracing new technologies and proactive maintenance strategies will undoubtedly shape the future of lubrication in the industries utilizing Metra forms.

For pdfFiller’s FAQs

Below is a list of the most common customer questions. If you can’t find an answer to your question, please don’t hesitate to reach out to us.

How do I edit oil lubricants for metra on an iOS device?

How do I edit oil lubricants for metra on an Android device?

How do I fill out oil lubricants for metra on an Android device?

What is oil lubricants for metra?

Who is required to file oil lubricants for metra?

How to fill out oil lubricants for metra?

What is the purpose of oil lubricants for metra?

What information must be reported on oil lubricants for metra?

pdfFiller is an end-to-end solution for managing, creating, and editing documents and forms in the cloud. Save time and hassle by preparing your tax forms online.