Get the free Repair of Aljon Compactor for Public Works

Get, Create, Make and Sign repair of aljon compactor

How to edit repair of aljon compactor online

Uncompromising security for your PDF editing and eSignature needs

How to fill out repair of aljon compactor

How to fill out repair of aljon compactor

Who needs repair of aljon compactor?

Repair of Aljon Compactor Form

Understanding the Aljon compactor

The Aljon compactor is an industry-leading piece of equipment known for its efficiency and durability, designed primarily for waste management and recycling operations. By compressing materials into compact bales, these machines optimize transport and processing. Understanding the intrinsic workings of these machines is crucial for operators and maintenance teams to ensure peak performance.

Common issues with Aljon compactors typically include hydraulic leaks, electrical failures, and excessive wear on components such as the frame and compacting plates. Regular maintenance and timely repairs are essential to prevent minor issues from escalating into costly repairs, thereby extending the unit's operational life.

Prompt repairs can help maintain the factory warranty and improve operational efficiency. Regular inspections and understanding when to act can significantly impact the overall business's bottom line.

Preparing for the repair process

The initial step in the repair process is accurately identifying the problem. Symptoms of malfunction may vary, from unusual noises to performance dips. Operators should observe any inconsistencies in the compactor's functions and performance, as this can highlight the issue at hand.

Diagnostic tools, such as pressure gauges and electrical meters, can provide insights into potential problems. Having model specifics readily available is critical, as it enables technicians to access manufacturer support documentation, thereby facilitating a more streamlined repair process.

Repair of Aljon compactor resources

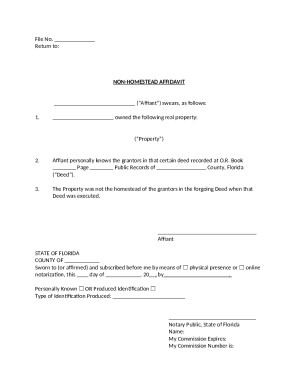

Essential forms play a vital role in the repair process. Repair request forms allow operators to document issues and request servicing efficiently. Additionally, equipment maintenance logs provide historical data that enables technicians to assess trends and potential reoccurring issues.

Troubleshooting forms are invaluable for guiding users through systematic checks. These might include step-by-step troubleshooting guides and checklists that help pinpoint common issues before initiating repairs.

Step-by-step repair instructions

Disassembling the Aljon compactor should be approached methodically to ensure all components are carefully handled. Essential tools include wrenches, screwdrivers, and safety gear such as gloves and goggles. Operators should always prioritize safety, ensuring that energy sources are disconnected before starting any repair work.

Once disassembled, diagnosing parts for repair or replacement is critical. Key components to check include hoses for hydraulic systems, electrical connections, and the condition of the frame. Assessing the viability of these parts often requires professional insight.

Common repairs may involve addressing hydraulic leaks or faults in the electrical system. Replacement parts can be sourced through authorized dealers or OEM certified remanufacturing services, ensuring quality and compatibility.

Following repairs, reassembly must occur with attention to detail. Reassembling the compactor involves reverse-order steps from disassembly and double-checking repairs to confirm that every component is secure and functioning correctly.

Documenting the repair process

Filling out repair forms accurately is crucial for maintaining quality records. Accurate documentation can assist future troubleshooting efforts and ensure that manufacturers’ guidelines are followed. Important information includes details on troubleshooting conducted, parts replaced, and the overall condition post-repair.

Best practices for digital documentation can be leveraged through services like pdfFiller. This platform enables users to create, edit, and store necessary forms online, ensuring easy access and collaboration. eSigning repair authorization forms can also be managed through this digital solution, streamlining workflows further.

Managing future repairs and maintenance

Setting up a maintenance schedule helps avert unexpected downtime. Recommended intervals for checks should be adhered to, ensuring that various system components are regularly inspected. Utilizing application reminders can help keep this schedule organized, prompting timely checks and repairs.

Continuous improvement strategies, such as conducting audits and reviewing repair logs, can reveal patterns in malfunctions or breakdowns. Analyzing these logs allows for proactive maintenance planning.

Engaging with support and resources

In more complex repair situations, contacting Aljon support is advisable. Their trained factory technicians can assist with intricate issues that require expert intervention, ensuring repairs meet quality standards.

Online communities and forums are useful resources to engage with fellow users. These platforms can facilitate knowledge sharing related to troubleshooting and maintenance. Recommendations for forums typically include specific groups dedicated to Aljon compactors, where users can share insights and advice.

Professional services for Aljon repair

Not all repair scenarios are suited for DIY approaches. Indicators that require expert intervention include persistent issues that cannot be easily diagnosed or repairs that jeopardize safety. Seeking professional help ensures that the repairs maintain the machine's integrity.

Finding certified repair services can save time and reduce long-term costs. When choosing reliable technicians, inquire about their experience with Aljon equipment, warranty implications of repairs, and any certifications they may hold. This diligence can prevent unexpected costs down the line.

Additional considerations

Cost considerations for repairs can vary widely based on the nature of the work done. Standard repairs may be manageable within a budget, while extensive repairs or parts replacements can significantly impact financial planning. It is advisable to include potential repair costs in operational budgets to ensure capable financial management.

Warranties can also play a critical role in the repair process. Understanding which repairs may void warranties is key, as improper repairs could lead to larger expenses over time. Always consult the warranty conditions to mitigate such risks.

Maximizing your compactor's lifespan

To maximize the lifespan of your Aljon compactor, best practices for ongoing maintenance should be established. Regular lubrication, prompt repairs when issues are identified, and training for operators on proper usage can greatly influence the unit's performance.

Additionally, considering upgrades and enhancements through retrofits can improve operating efficiency. Many new technologies can be integrated into existing systems to elevate performance, making it advisable to consult with repair technicians about available options.

For pdfFiller’s FAQs

Below is a list of the most common customer questions. If you can’t find an answer to your question, please don’t hesitate to reach out to us.

How can I manage my repair of aljon compactor directly from Gmail?

How can I send repair of aljon compactor for eSignature?

How do I fill out the repair of aljon compactor form on my smartphone?

What is repair of aljon compactor?

Who is required to file repair of aljon compactor?

How to fill out repair of aljon compactor?

What is the purpose of repair of aljon compactor?

What information must be reported on repair of aljon compactor?

pdfFiller is an end-to-end solution for managing, creating, and editing documents and forms in the cloud. Save time and hassle by preparing your tax forms online.