Get the free LEAF SPRINGS

Show details

235LEAF SPRINGS 181/16 181/16 “Trailer Spring, Single Leaf Low 43/8 Arch 42.5 Axle Spacing, 22,400 lb. GAR Hutches 705142 Part No. TSTRA026 227/8 213/4 “Trailer Spring, Single Leaf Low Arch 22,400

We are not affiliated with any brand or entity on this form

Get, Create, Make and Sign

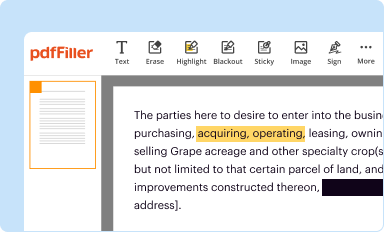

Edit your leaf springs form online

Type text, complete fillable fields, insert images, highlight or blackout data for discretion, add comments, and more.

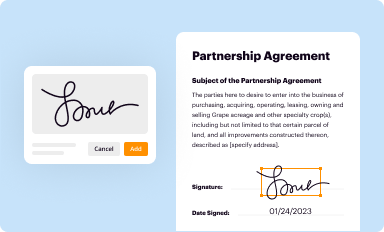

Add your legally-binding signature

Draw or type your signature, upload a signature image, or capture it with your digital camera.

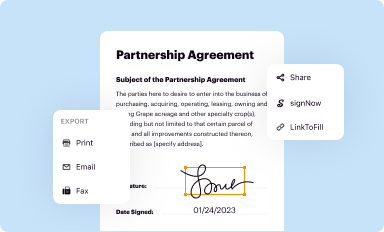

Share your form instantly

Email, fax, or share your leaf springs form via URL. You can also download, print, or export forms to your preferred cloud storage service.

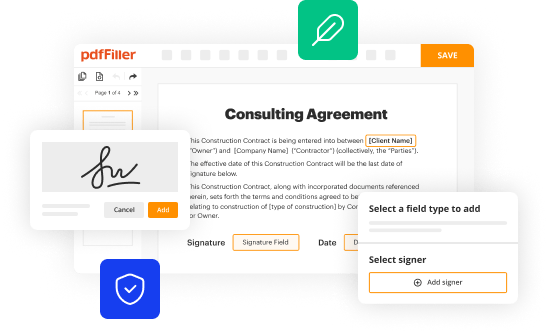

Editing leaf springs online

In order to make advantage of the professional PDF editor, follow these steps below:

1

Check your account. If you don't have a profile yet, click Start Free Trial and sign up for one.

2

Simply add a document. Select Add New from your Dashboard and import a file into the system by uploading it from your device or importing it via the cloud, online, or internal mail. Then click Begin editing.

3

Edit leaf springs. Replace text, adding objects, rearranging pages, and more. Then select the Documents tab to combine, divide, lock or unlock the file.

4

Save your file. Select it from your records list. Then, click the right toolbar and select one of the various exporting options: save in numerous formats, download as PDF, email, or cloud.

With pdfFiller, it's always easy to work with documents.

How to fill out leaf springs

How to fill out leaf springs:

01

Start by removing the old leaf springs from the vehicle. This involves loosening the bolts or clips that hold the springs in place and carefully lowering them down.

02

Inspect the leaf springs for any signs of damage or wear. Look for cracks, rust, or any bent or broken leaves. If you notice any issues, it's recommended to replace the leaf springs rather than attempting to fill them out.

03

Clean the leaf springs thoroughly using a wire brush or sandpaper to remove any dirt, debris, or rust. This will ensure proper adhesion of the filling material and help improve the overall durability of the leaf springs.

04

Apply a suitable filler material to any cracks or damaged areas on the leaf springs. There are various options available, such as epoxy putty or specialized metal fillers. Follow the manufacturer's instructions for mixing and applying the filler, making sure to fill out the damaged sections evenly.

05

Allow the filler to dry or cure completely according to the recommended time frame provided by the manufacturer. This may involve keeping the leaf springs in a well-ventilated area or using a heat source to accelerate the drying process.

06

Once the filler is fully cured, sand down any excess or rough areas on the leaf springs to create a smooth surface. This will prevent any interference with the suspension system when the leaf springs are reinstalled.

07

Before reinstalling the leaf springs, it's essential to check the mounting hardware, bolts, and clips for any signs of damage or wear. Replace any worn or damaged components to ensure a secure and safe installation.

08

Carefully align the leaf springs with their respective mounting points, making sure they are positioned correctly. Use a torque wrench to tighten the bolts or clips to the manufacturer's recommended specifications.

09

After the leaf springs are securely in place, test the vehicle's suspension to ensure everything is functioning correctly. Take it for a short drive and listen for any unusual noises or vibrations. If everything feels and sounds normal, the leaf springs have been successfully filled out and installed.

Who needs leaf springs:

01

Leaf springs are commonly used in the suspension systems of vehicles, particularly trucks and SUVs. They provide support, stability, and proper weight distribution, making them essential for vehicles that carry heavy loads or tow trailers.

02

Commercial vehicles, such as delivery trucks, vans, or buses, often rely on leaf springs to handle the added weight capacity and ensure a smooth and controlled ride.

03

Off-road enthusiasts and adventure seekers who enjoy exploring rugged terrains often opt for vehicles with leaf spring suspensions. Leaf springs offer improved articulation and durability, allowing these vehicles to handle rough conditions and uneven surfaces more effectively.

04

Classic or vintage car enthusiasts may also require leaf springs when restoring or maintaining their vehicles. These springs are often used in older models and play a crucial role in preserving the authenticity and performance of these cars.

05

Some utility trailers, recreational vehicles, and boats may also utilize leaf springs for their suspension systems. These springs help maintain stability and handling while transporting heavy loads or navigating various road conditions.

Overall, anyone who owns a vehicle or equipment that requires load-bearing capacity, stability, or a specialized suspension system may need leaf springs. They are essential components that enhance performance, safety, and overall driving experience.

Fill form : Try Risk Free

For pdfFiller’s FAQs

Below is a list of the most common customer questions. If you can’t find an answer to your question, please don’t hesitate to reach out to us.

What is leaf springs?

Leaf springs are a type of suspension system commonly used in vehicles to absorb and distribute weight.

Who is required to file leaf springs?

Manufacturers and distributors of vehicles equipped with leaf springs are required to file leaf springs.

How to fill out leaf springs?

Leaf springs are typically filled out with information about the vehicle make and model, the specific leaf spring used, and any relevant testing or compliance information.

What is the purpose of leaf springs?

The purpose of leaf springs is to provide support and stability to a vehicle's suspension system, helping to absorb shock and maintain proper ride height.

What information must be reported on leaf springs?

Information such as the material used, load capacity, dimensions, and manufacturer details must be reported on leaf springs.

When is the deadline to file leaf springs in 2023?

The deadline to file leaf springs in 2023 is typically at the end of the fiscal year, which is December 31st.

What is the penalty for the late filing of leaf springs?

The penalty for late filing of leaf springs can vary, but may include fines, penalties, and potentially legal action depending on the jurisdiction.

Where do I find leaf springs?

The premium pdfFiller subscription gives you access to over 25M fillable templates that you can download, fill out, print, and sign. The library has state-specific leaf springs and other forms. Find the template you need and change it using powerful tools.

How do I edit leaf springs online?

With pdfFiller, it's easy to make changes. Open your leaf springs in the editor, which is very easy to use and understand. When you go there, you'll be able to black out and change text, write and erase, add images, draw lines, arrows, and more. You can also add sticky notes and text boxes.

How do I edit leaf springs straight from my smartphone?

You may do so effortlessly with pdfFiller's iOS and Android apps, which are available in the Apple Store and Google Play Store, respectively. You may also obtain the program from our website: https://edit-pdf-ios-android.pdffiller.com/. Open the application, sign in, and begin editing leaf springs right away.

Fill out your leaf springs online with pdfFiller!

pdfFiller is an end-to-end solution for managing, creating, and editing documents and forms in the cloud. Save time and hassle by preparing your tax forms online.

Not the form you were looking for?

Keywords

Related Forms

If you believe that this page should be taken down, please follow our DMCA take down process

here

.