Get the free Glass passivated chip junction

Show details

15MBNaina Semiconductor Ltd. Single Phase Bridge Rectifier Features Glass passivated chip junction Surge capability of 300 A High efficiency Electrically isolated metal case for maximum heat dissipation

We are not affiliated with any brand or entity on this form

Get, Create, Make and Sign

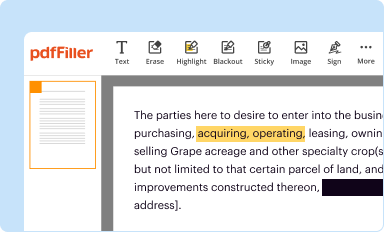

Edit your glass passivated chip junction form online

Type text, complete fillable fields, insert images, highlight or blackout data for discretion, add comments, and more.

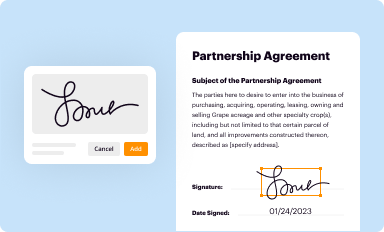

Add your legally-binding signature

Draw or type your signature, upload a signature image, or capture it with your digital camera.

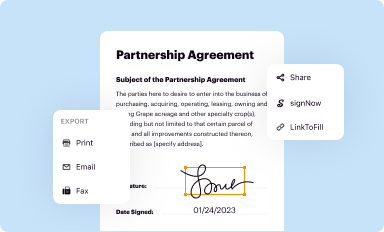

Share your form instantly

Email, fax, or share your glass passivated chip junction form via URL. You can also download, print, or export forms to your preferred cloud storage service.

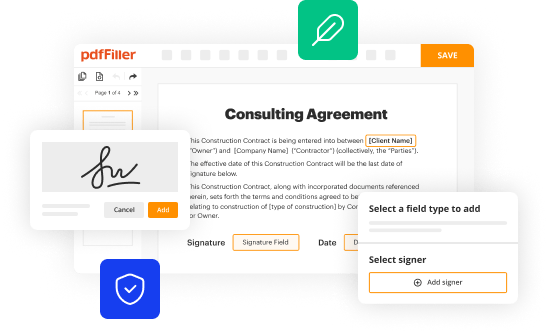

Editing glass passivated chip junction online

Follow the steps below to take advantage of the professional PDF editor:

1

Set up an account. If you are a new user, click Start Free Trial and establish a profile.

2

Prepare a file. Use the Add New button. Then upload your file to the system from your device, importing it from internal mail, the cloud, or by adding its URL.

3

Edit glass passivated chip junction. Rearrange and rotate pages, add and edit text, and use additional tools. To save changes and return to your Dashboard, click Done. The Documents tab allows you to merge, divide, lock, or unlock files.

4

Save your file. Choose it from the list of records. Then, shift the pointer to the right toolbar and select one of the several exporting methods: save it in multiple formats, download it as a PDF, email it, or save it to the cloud.

Dealing with documents is always simple with pdfFiller.

How to fill out glass passivated chip junction

How to fill out glass passivated chip junction:

01

Clean the surface of the chip junction using a lint-free cloth and an appropriate cleaning solution. Make sure to remove any dust or debris that may interfere with the bonding process.

02

Apply a thin layer of adhesive to the glass passivated chip junction. Use a precision dispenser or a small brush to ensure an even application.

03

Carefully place the chip onto the adhesive layer, aligning the bonding pads with the corresponding pads on the junction.

04

Gently press the chip onto the adhesive to ensure proper bonding. Avoid applying excessive force as it may damage the chip or the junction.

05

Allow the adhesive to cure according to the manufacturer's instructions. This may involve heating the junction to a specific temperature for a certain period of time.

06

Once the adhesive has fully cured, inspect the chip junction to ensure that it is securely bonded. Check for any visible defects or inconsistencies that may affect its performance.

Who needs glass passivated chip junction?

01

Electronic manufacturers: Glass passivated chip junctions are commonly used in the production of various electronic devices, such as microchips, integrated circuits, and transistors. Manufacturers require these junctions to protect the delicate components and enhance their performance.

02

Research and development laboratories: R&D labs may also need glass passivated chip junctions for prototyping or testing purposes. These junctions provide a reliable platform for studying the behavior and characteristics of different electronic components.

03

Repair and maintenance technicians: Professionals involved in repairing and maintaining electronic devices may require glass passivated chip junctions to replace damaged or faulty junctions. By using these junctions, technicians can ensure the proper functioning and longevity of the repaired devices.

Fill form : Try Risk Free

For pdfFiller’s FAQs

Below is a list of the most common customer questions. If you can’t find an answer to your question, please don’t hesitate to reach out to us.

What is glass passivated chip junction?

Glass passivated chip junction refers to the process of using a thin layer of glass to passivate the surface of a semiconductor chip.

Who is required to file glass passivated chip junction?

Manufacturers and suppliers of semiconductor chips are required to file glass passivated chip junction.

How to fill out glass passivated chip junction?

Glass passivated chip junction can be filled out by providing information about the semiconductor chip, the process used for passivation, and any other relevant details.

What is the purpose of glass passivated chip junction?

The purpose of glass passivated chip junction is to protect the semiconductor chip from environmental factors and improve its performance.

What information must be reported on glass passivated chip junction?

Information such as the type of semiconductor chip, the passivation technique used, and any testing results must be reported on the glass passivated chip junction.

When is the deadline to file glass passivated chip junction in 2023?

The deadline to file glass passivated chip junction in 2023 is December 31st.

What is the penalty for the late filing of glass passivated chip junction?

The penalty for the late filing of glass passivated chip junction may include fines or restrictions on selling the semiconductor chips.

How can I edit glass passivated chip junction from Google Drive?

You can quickly improve your document management and form preparation by integrating pdfFiller with Google Docs so that you can create, edit and sign documents directly from your Google Drive. The add-on enables you to transform your glass passivated chip junction into a dynamic fillable form that you can manage and eSign from any internet-connected device.

How do I edit glass passivated chip junction on an Android device?

The pdfFiller app for Android allows you to edit PDF files like glass passivated chip junction. Mobile document editing, signing, and sending. Install the app to ease document management anywhere.

How do I complete glass passivated chip junction on an Android device?

On an Android device, use the pdfFiller mobile app to finish your glass passivated chip junction. The program allows you to execute all necessary document management operations, such as adding, editing, and removing text, signing, annotating, and more. You only need a smartphone and an internet connection.

Fill out your glass passivated chip junction online with pdfFiller!

pdfFiller is an end-to-end solution for managing, creating, and editing documents and forms in the cloud. Save time and hassle by preparing your tax forms online.

Not the form you were looking for?

Keywords

Related Forms

If you believe that this page should be taken down, please follow our DMCA take down process

here

.