The data also show that a novel strategy for optimizing the network is possible. A novel approach to the optimization has been proposed which includes an interactive and predictive optimization method based on the Neural Network approach. BACKGROUND DESCRIPTION Polanski, N.V.; Aguilar, H.C.; Maciej Filho, R Laboratory of Optimization Design and Advanced Process Control. Faculty of Chemical EngineeringState University of Campinas, P.O.

Get the free Simulation of pulping process using neural networks and hybrid model - nt ntnu

Show details

SIMULATION OF PULPING PROCESS USING NEURAL NETWORKS AND HYBRID MODEL Polanski, N.V.; Aguilar, H.C.; Maciej Filho, R. Laboratory of Optimization Design and Advanced Process Control. Faculty of Chemical

We are not affiliated with any brand or entity on this form

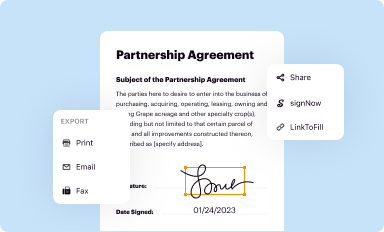

Get, Create, Make and Sign

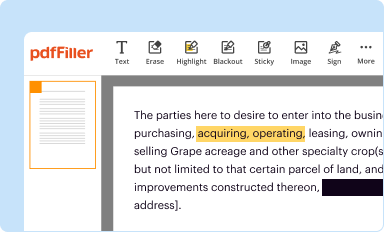

Edit your simulation of pulping process form online

Type text, complete fillable fields, insert images, highlight or blackout data for discretion, add comments, and more.

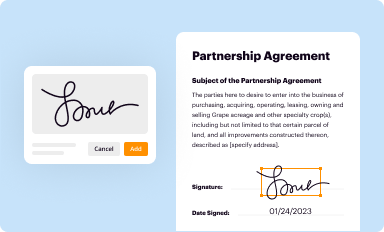

Add your legally-binding signature

Draw or type your signature, upload a signature image, or capture it with your digital camera.

Share your form instantly

Email, fax, or share your simulation of pulping process form via URL. You can also download, print, or export forms to your preferred cloud storage service.

How to edit simulation of pulping process online

Follow the steps down below to take advantage of the professional PDF editor:

1

Log in. Click Start Free Trial and create a profile if necessary.

2

Upload a document. Select Add New on your Dashboard and transfer a file into the system in one of the following ways: by uploading it from your device or importing from the cloud, web, or internal mail. Then, click Start editing.

3

Edit simulation of pulping process. Replace text, adding objects, rearranging pages, and more. Then select the Documents tab to combine, divide, lock or unlock the file.

4

Save your file. Choose it from the list of records. Then, shift the pointer to the right toolbar and select one of the several exporting methods: save it in multiple formats, download it as a PDF, email it, or save it to the cloud.

It's easier to work with documents with pdfFiller than you can have believed. You may try it out for yourself by signing up for an account.

Fill form : Try Risk Free

For pdfFiller’s FAQs

Below is a list of the most common customer questions. If you can’t find an answer to your question, please don’t hesitate to reach out to us.

What is simulation of pulping process?

Simulation of pulping process is a computer-based modeling and analysis technique used to replicate the behavior and performance of the pulping process in a virtual environment. It helps in predicting the outcome of various process parameters and optimizing the process for better efficiency and productivity.

Who is required to file simulation of pulping process?

The entities or organizations engaged in the pulping industry, such as pulp manufacturers or research institutions, are required to file the simulation of pulping process.

How to fill out simulation of pulping process?

To fill out the simulation of pulping process, you need to perform the following steps:

1. Gather relevant process data and parameters.

2. Use simulation software or tools to model the pulping process.

3. Input the collected data into the simulation model.

4. Run the simulation to generate results.

5. Document the simulation methodology and results.

6. Prepare a report summarizing the simulation findings.

What is the purpose of simulation of pulping process?

The purpose of simulation of pulping process is to analyze and optimize the pulping operations, improve product quality, reduce production costs, and minimize environmental impact. It helps in understanding the complex dynamics of the pulping process and enables process engineers to make informed decisions for process improvement.

What information must be reported on simulation of pulping process?

The simulation of pulping process report should include the following information:

1. Description of the simulated pulping process.

2. Input parameters used in the simulation.

3. Detailed methodology and assumptions made.

4. Results and analysis of the simulation.

5. Conclusions and recommendations based on the simulation findings.

When is the deadline to file simulation of pulping process in 2023?

The deadline to file the simulation of pulping process in 2023 is dependent on specific regulations or requirements set by the governing authorities. It is advisable to consult the relevant regulatory bodies or industry guidelines for the exact deadline.

What is the penalty for the late filing of simulation of pulping process?

The penalty for the late filing of simulation of pulping process can vary depending on the jurisdiction and applicable regulations. It is recommended to review the specific rules and guidelines provided by the governing authorities to determine the penalties for late filing.

How can I modify simulation of pulping process without leaving Google Drive?

It is possible to significantly enhance your document management and form preparation by combining pdfFiller with Google Docs. This will allow you to generate papers, amend them, and sign them straight from your Google Drive. Use the add-on to convert your simulation of pulping process into a dynamic fillable form that can be managed and signed using any internet-connected device.

Can I sign the simulation of pulping process electronically in Chrome?

You certainly can. You get not just a feature-rich PDF editor and fillable form builder with pdfFiller, but also a robust e-signature solution that you can add right to your Chrome browser. You may use our addon to produce a legally enforceable eSignature by typing, sketching, or photographing your signature with your webcam. Choose your preferred method and eSign your simulation of pulping process in minutes.

How do I fill out simulation of pulping process using my mobile device?

On your mobile device, use the pdfFiller mobile app to complete and sign simulation of pulping process. Visit our website (https://edit-pdf-ios-android.pdffiller.com/) to discover more about our mobile applications, the features you'll have access to, and how to get started.

Fill out your simulation of pulping process online with pdfFiller!

pdfFiller is an end-to-end solution for managing, creating, and editing documents and forms in the cloud. Save time and hassle by preparing your tax forms online.

Not the form you were looking for?

Keywords

Related Forms

If you believe that this page should be taken down, please follow our DMCA take down process

here

.