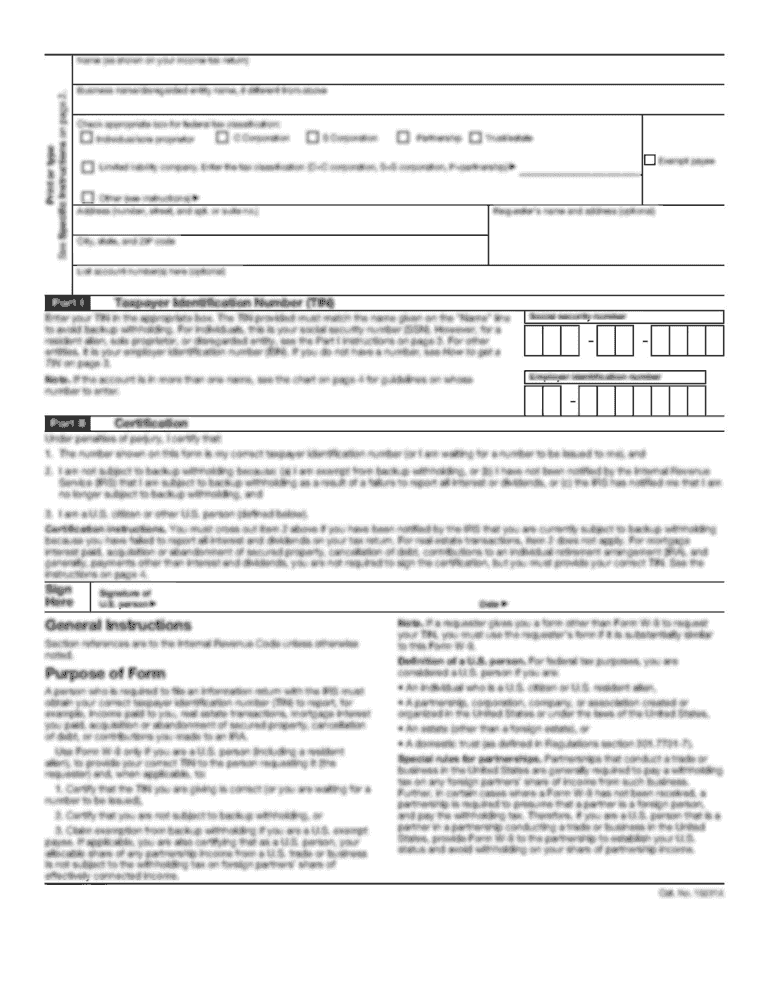

Get the free Using Predictive Maintenance to Approach Zero Downtime Explore how companies can emp...

Show details

SAP Thought Leadership Paper Predictive Maintenance Using Predictive Maintenance to Approach Zero Downtime 2015 SAP SE or an SAP affiliate company. All rights reserved. How Predictive Analytics Makes

We are not affiliated with any brand or entity on this form

Get, Create, Make and Sign

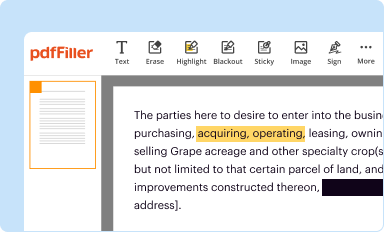

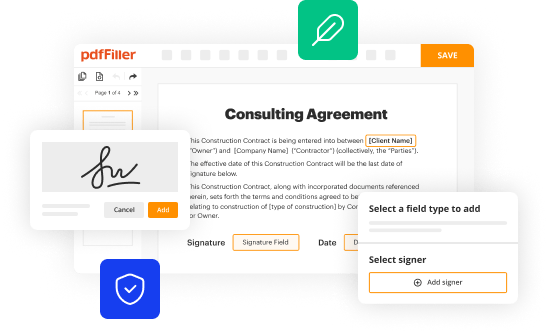

Edit your using predictive maintenance to form online

Type text, complete fillable fields, insert images, highlight or blackout data for discretion, add comments, and more.

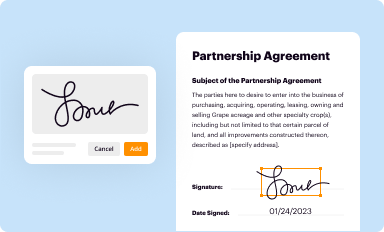

Add your legally-binding signature

Draw or type your signature, upload a signature image, or capture it with your digital camera.

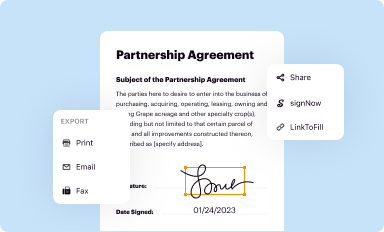

Share your form instantly

Email, fax, or share your using predictive maintenance to form via URL. You can also download, print, or export forms to your preferred cloud storage service.

How to edit using predictive maintenance to online

Use the instructions below to start using our professional PDF editor:

1

Set up an account. If you are a new user, click Start Free Trial and establish a profile.

2

Upload a file. Select Add New on your Dashboard and upload a file from your device or import it from the cloud, online, or internal mail. Then click Edit.

3

Edit using predictive maintenance to. Add and replace text, insert new objects, rearrange pages, add watermarks and page numbers, and more. Click Done when you are finished editing and go to the Documents tab to merge, split, lock or unlock the file.

4

Save your file. Select it from your records list. Then, click the right toolbar and select one of the various exporting options: save in numerous formats, download as PDF, email, or cloud.

With pdfFiller, dealing with documents is always straightforward.

How to fill out using predictive maintenance to

How to fill out using predictive maintenance to:

01

Identify critical assets: Start by identifying the assets that are vital to your operations and could significantly impact your productivity if they fail. This could include machinery, equipment, or systems that are essential for your business.

02

Implement condition monitoring: Once you have identified your critical assets, implement condition monitoring techniques to continuously monitor their performance. This can involve using sensors, data collection tools, or software to track various parameters such as temperature, vibration, or lubrication levels.

03

Collect and analyze data: Collect data from the condition monitoring activities and analyze it to identify patterns or anomalies that could indicate potential failures. This can be done using advanced analytics or machine learning algorithms that can detect early warning signs.

04

Set up predictive maintenance thresholds: Based on the analysis of the collected data, establish thresholds for each asset that indicate when maintenance actions should be taken. These thresholds can be based on historical data, manufacturer's recommendations, or industry best practices.

05

Develop maintenance plans: Use the insights gained from the data analysis to create maintenance plans for each asset. These plans should outline the specific actions to be taken, such as scheduled maintenance tasks, component replacements, or repairs, to prevent potential failures or minimize downtime.

06

Schedule and execute maintenance activities: Once the maintenance plans are developed, schedule the required activities according to priority and operational constraints. Ensure that the necessary resources, such as manpower and spare parts, are available to carry out the maintenance tasks effectively.

Who needs using predictive maintenance to:

01

Manufacturing industries: Predictive maintenance is particularly beneficial for manufacturing industries that heavily rely on production equipment and machinery. By implementing predictive maintenance techniques, manufacturers can minimize unplanned downtime, optimize equipment utilization, and improve overall productivity.

02

Transportation and logistics: Predictive maintenance can be applied to vehicles, infrastructure, and other critical assets in the transportation and logistics sector. This helps in ensuring the safe and efficient operation of vehicles, reducing maintenance costs, and enhancing customer satisfaction through reliable services.

03

Energy and utilities: Power plants, renewable energy facilities, and utility companies can benefit from predictive maintenance to optimize the performance of their assets. By proactively addressing potential faults or failures, they can avoid costly shutdowns, maximize uptime, and improve the reliability of energy supply.

04

Healthcare facilities: Predictive maintenance can be used in healthcare facilities to monitor and maintain critical medical equipment, ensuring patient safety and uninterrupted healthcare services. By detecting equipment failures in advance, healthcare providers can minimize the risk of service disruptions and enhance patient care.

05

Any industry with critical assets: Predictive maintenance can be valuable for any industry that relies on critical assets for their operations, including oil and gas, telecommunications, food processing, and many others. By implementing predictive maintenance strategies, these industries can reduce equipment downtime, extend asset lifespans, and optimize maintenance resources.

In conclusion, the process of using predictive maintenance involves identifying critical assets, implementing condition monitoring, collecting and analyzing data, setting up maintenance thresholds, developing maintenance plans, and executing these plans. Various industries, including manufacturing, transportation, energy, healthcare, and others, can benefit from implementing predictive maintenance techniques.

Fill form : Try Risk Free

For pdfFiller’s FAQs

Below is a list of the most common customer questions. If you can’t find an answer to your question, please don’t hesitate to reach out to us.

How do I modify my using predictive maintenance to in Gmail?

using predictive maintenance to and other documents can be changed, filled out, and signed right in your Gmail inbox. You can use pdfFiller's add-on to do this, as well as other things. When you go to Google Workspace, you can find pdfFiller for Gmail. You should use the time you spend dealing with your documents and eSignatures for more important things, like going to the gym or going to the dentist.

How do I edit using predictive maintenance to in Chrome?

Install the pdfFiller Google Chrome Extension in your web browser to begin editing using predictive maintenance to and other documents right from a Google search page. When you examine your documents in Chrome, you may make changes to them. With pdfFiller, you can create fillable documents and update existing PDFs from any internet-connected device.

How do I complete using predictive maintenance to on an Android device?

On Android, use the pdfFiller mobile app to finish your using predictive maintenance to. Adding, editing, deleting text, signing, annotating, and more are all available with the app. All you need is a smartphone and internet.

Fill out your using predictive maintenance to online with pdfFiller!

pdfFiller is an end-to-end solution for managing, creating, and editing documents and forms in the cloud. Save time and hassle by preparing your tax forms online.

Not the form you were looking for?

Keywords

Related Forms

If you believe that this page should be taken down, please follow our DMCA take down process

here

.