Get the free GMAW vs FCAW-S Process - Lincoln Electric

Show details

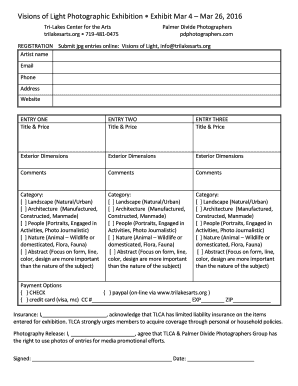

OM-226 288T 2011?12 Processes MIG (GMAC) Welding Flux Cored (FLAW) Welding Description Wire Feeder R Suitcase EXTREME 8VS CE And Non-CE Models File: MIG (GMAC) Visit our website at www.MillerWelds.com

We are not affiliated with any brand or entity on this form

Get, Create, Make and Sign

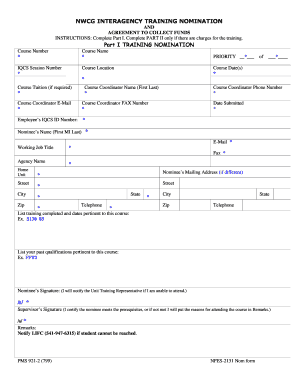

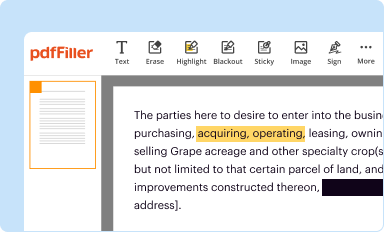

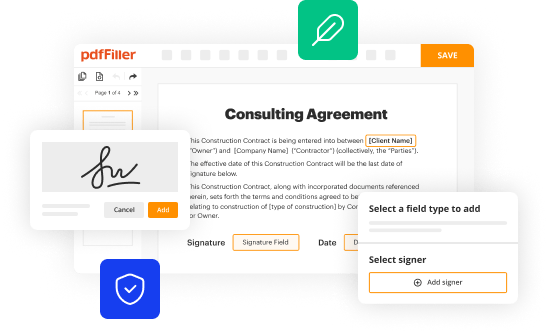

Edit your gmaw vs fcaw-s process form online

Type text, complete fillable fields, insert images, highlight or blackout data for discretion, add comments, and more.

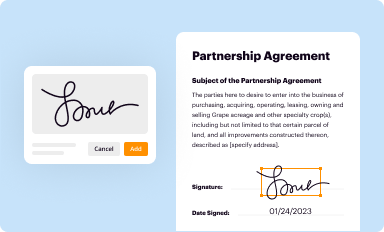

Add your legally-binding signature

Draw or type your signature, upload a signature image, or capture it with your digital camera.

Share your form instantly

Email, fax, or share your gmaw vs fcaw-s process form via URL. You can also download, print, or export forms to your preferred cloud storage service.

Editing gmaw vs fcaw-s process online

Follow the guidelines below to benefit from a competent PDF editor:

1

Create an account. Begin by choosing Start Free Trial and, if you are a new user, establish a profile.

2

Prepare a file. Use the Add New button to start a new project. Then, using your device, upload your file to the system by importing it from internal mail, the cloud, or adding its URL.

3

Edit gmaw vs fcaw-s process. Add and replace text, insert new objects, rearrange pages, add watermarks and page numbers, and more. Click Done when you are finished editing and go to the Documents tab to merge, split, lock or unlock the file.

4

Get your file. Select your file from the documents list and pick your export method. You may save it as a PDF, email it, or upload it to the cloud.

The use of pdfFiller makes dealing with documents straightforward.

How to fill out gmaw vs fcaw-s process

How to fill out gmaw vs fcaw-s process:

01

First, gather all the necessary materials and equipment, including welding machine, welding electrode, safety gear such as gloves and goggles, and the workpiece that needs to be welded.

02

Next, set up the welding machine according to the specific process you are using. Adjust the voltage, wire feed speed, and any other relevant parameters as per the recommended settings for the chosen process.

03

Prepare the workpiece by cleaning and removing any contaminants such as rust, oil, or dirt. This can be done using solvent or a wire brush depending on the condition of the surface.

04

Choose the appropriate welding electrode for the process. GMAW (Gas Metal Arc Welding) uses a solid wire electrode, while FCAW-S (Flux-Cored Arc Welding - Self-Shielded) uses a tubular wire with flux inside.

05

Install the welding electrode into the welding machine according to the manufacturer's instructions. Ensure that it is properly secured and threaded through the wire feeding system.

06

Put on the necessary safety gear, including gloves, goggles, and a welding helmet, to protect yourself from the welding arc and any potential hazards.

07

Position the workpiece in a stable and safe manner, ensuring that it is aligned correctly for the desired weld joint.

08

Start the welding process by activating the welding machine and initiating the arc. Move the welding electrode along the joint, maintaining a consistent travel speed and angle to achieve proper penetration and a sound weld.

09

Continue welding until the entire joint is completed. Make sure to evenly distribute the weld bead and avoid any excessive buildup or undercutting.

10

Once finished, allow the weld to cool down and inspect it for any defects or imperfections. Use appropriate testing methods such as visual examination or non-destructive testing if required.

Who needs gmaw vs fcaw-s process:

01

Welders who are working on various projects that require different welding processes.

02

Industries and manufacturing sectors that deal with metal fabrication, construction, automotive, aerospace, and shipbuilding.

03

Professionals and hobbyists involved in structural welding, pipe welding, or general maintenance and repair work.

Fill form : Try Risk Free

For pdfFiller’s FAQs

Below is a list of the most common customer questions. If you can’t find an answer to your question, please don’t hesitate to reach out to us.

What is gmaw vs fcaw-s process?

GMAW vs FCAW-S process refers to two different welding processes. GMAW stands for Gas Metal Arc Welding, also known as MIG welding, while FCAW-S stands for Flux-Cored Arc Welding - Self Shielded. GMAW process uses a solid wire electrode and shielding gas to protect the welding area, whereas FCAW-S process uses a tubular electrode with a flux core, eliminating the need for external shielding gas.

Who is required to file gmaw vs fcaw-s process?

Welding professionals and companies involved in welding activities are usually required to file gmaw vs fcaw-s process.

How to fill out gmaw vs fcaw-s process?

To fill out the gmaw vs fcaw-s process, you need to gather the necessary information about the welding project, equipment used, welding parameters, and any relevant certifications. Then, you can use the designated form or documentation provided by the regulatory authority or welding industry standard to record and report the required information.

What is the purpose of gmaw vs fcaw-s process?

The purpose of gmaw vs fcaw-s process is to ensure proper documentation and reporting of welding activities. It helps to track and monitor welding operations, maintain quality control, and ensure compliance with applicable welding standards and regulations.

What information must be reported on gmaw vs fcaw-s process?

The information that must be reported on gmaw vs fcaw-s process typically includes details about the welding project, such as the location, date, and duration of the welding activity, welding equipment used, welding parameters (such as voltage, current, and wire feed speed), and any relevant certifications or qualifications of the welder.

When is the deadline to file gmaw vs fcaw-s process in 2023?

The specific deadline to file gmaw vs fcaw-s process in 2023 may vary depending on the jurisdiction or organization. It is recommended to consult the relevant regulatory authority or welding industry standard to determine the exact deadline.

What is the penalty for the late filing of gmaw vs fcaw-s process?

The penalties for late filing of gmaw vs fcaw-s process can vary depending on the jurisdiction or organization. It may include fines, penalties, or other consequences outlined in the applicable welding regulations or contractual agreements. It is advisable to consult the relevant regulatory authority or welding industry standard to understand the specific penalties for late filing.

Where do I find gmaw vs fcaw-s process?

With pdfFiller, an all-in-one online tool for professional document management, it's easy to fill out documents. Over 25 million fillable forms are available on our website, and you can find the gmaw vs fcaw-s process in a matter of seconds. Open it right away and start making it your own with help from advanced editing tools.

How do I edit gmaw vs fcaw-s process online?

With pdfFiller, you may not only alter the content but also rearrange the pages. Upload your gmaw vs fcaw-s process and modify it with a few clicks. The editor lets you add photos, sticky notes, text boxes, and more to PDFs.

How can I edit gmaw vs fcaw-s process on a smartphone?

The pdfFiller mobile applications for iOS and Android are the easiest way to edit documents on the go. You may get them from the Apple Store and Google Play. More info about the applications here. Install and log in to edit gmaw vs fcaw-s process.

Fill out your gmaw vs fcaw-s process online with pdfFiller!

pdfFiller is an end-to-end solution for managing, creating, and editing documents and forms in the cloud. Save time and hassle by preparing your tax forms online.

Not the form you were looking for?

Keywords

Related Forms

If you believe that this page should be taken down, please follow our DMCA take down process

here

.