Get the free VITRIFIED WHEELS

Show details

VITRIFIED WHEELS Norton vitrified toolroom wheels have set the standard for generations leading the way with technological improvements to maximize performance and productivity. Depend exclusively

We are not affiliated with any brand or entity on this form

Get, Create, Make and Sign

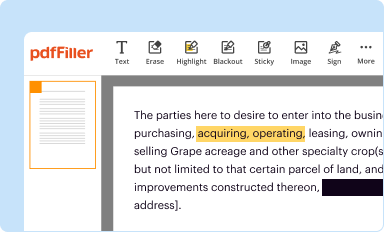

Edit your vitrified wheels form online

Type text, complete fillable fields, insert images, highlight or blackout data for discretion, add comments, and more.

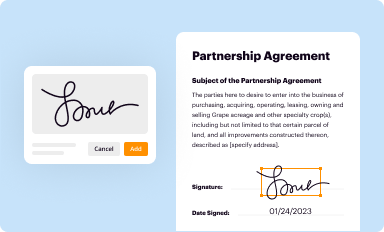

Add your legally-binding signature

Draw or type your signature, upload a signature image, or capture it with your digital camera.

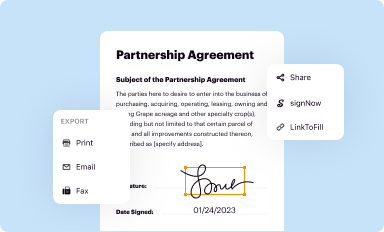

Share your form instantly

Email, fax, or share your vitrified wheels form via URL. You can also download, print, or export forms to your preferred cloud storage service.

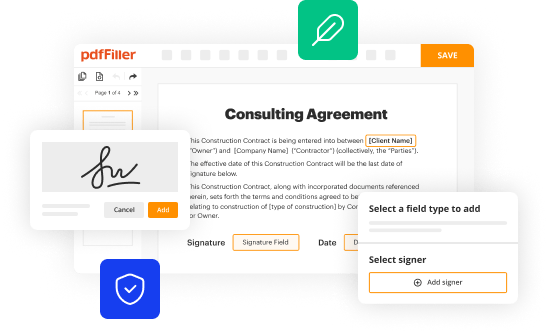

How to edit vitrified wheels online

To use the services of a skilled PDF editor, follow these steps below:

1

Log in. Click Start Free Trial and create a profile if necessary.

2

Upload a file. Select Add New on your Dashboard and upload a file from your device or import it from the cloud, online, or internal mail. Then click Edit.

3

Edit vitrified wheels. Rearrange and rotate pages, add and edit text, and use additional tools. To save changes and return to your Dashboard, click Done. The Documents tab allows you to merge, divide, lock, or unlock files.

4

Save your file. Choose it from the list of records. Then, shift the pointer to the right toolbar and select one of the several exporting methods: save it in multiple formats, download it as a PDF, email it, or save it to the cloud.

It's easier to work with documents with pdfFiller than you could have believed. You may try it out for yourself by signing up for an account.

How to fill out vitrified wheels

How to fill out vitrified wheels:

01

Start by inspecting the vitrified wheel for any damage or defects. Check for cracks, chips, or excessive wear. If there are any issues, do not use the wheel and replace it with a new one.

02

Mount the vitrified wheel securely on a compatible grinding machine or tool. Follow the manufacturer's instructions for proper wheel mounting to ensure safe and efficient operation.

03

Make sure to use the appropriate wheel flanges and tighten them securely to prevent any movement or slippage during use.

04

Before starting the grinding process, dress the wheel if necessary. Dressing involves removing any built-up residues or debris from the wheel surface to maintain its cutting performance and shape. Use a diamond dresser or dressing stick for this step.

05

Adjust the machine's speed and feed rates according to the material being ground and the desired outcome. Consult the wheel manufacturer's recommendations for optimal operating conditions.

06

Always wear appropriate personal protective equipment (PPE) such as safety glasses, gloves, and a face shield to protect against flying debris and hazards during the grinding process.

07

Start the grinding operation by gently bringing the vitrified wheel into contact with the workpiece. Apply consistent pressure and maintain a steady motion to achieve the desired grinding result.

08

Regularly monitor the wheel's performance during grinding. If you notice any vibrations, excessive heat, or loss of cutting efficiency, stop the operation and check for any issues. Adjust the machine settings or replace the wheel if necessary.

09

After completing the grinding task, let the vitrified wheel cool down before removing it from the machine. This will help prevent any damage or warping of the wheel due to sudden temperature changes.

Who needs vitrified wheels:

01

Metal fabricators and manufacturers: Vitrified wheels are commonly used in metalworking industries for various applications such as cutting, grinding, and sharpening metal materials. They are essential tools for shaping and finishing metal components.

02

Woodworkers: Vitrified wheels can also be beneficial for woodworkers when used with a grinding machine. They can be used to shape, sharpen, or smooth wood surfaces, especially when dealing with harder or denser wood types.

03

DIY enthusiasts and hobbyists: Individuals who enjoy DIY projects or have a hobby that involves working with metal or wood may find vitrified wheels useful. They provide an efficient and precise way to shape or refine materials, bringing professional-level results to their projects.

04

Automotive and aerospace industries: Vitrified wheels are widely used in these industries for tasks such as cutting, grinding, and polishing various metal components, including engine parts, turbine blades, and aircraft structures. The high precision and durability of vitrified wheels make them ideal for these demanding applications.

Fill form : Try Risk Free

For pdfFiller’s FAQs

Below is a list of the most common customer questions. If you can’t find an answer to your question, please don’t hesitate to reach out to us.

What is vitrified wheels?

Vitrified wheels are grinding wheels made from a mixture of ceramics, bonding materials, and abrasive grains.

Who is required to file vitrified wheels?

Manufacturers and distributors of vitrified wheels are required to file.

How to fill out vitrified wheels?

Vitrified wheels are typically filled out with information such as type of wheel, size, manufacturer, and date of manufacture.

What is the purpose of vitrified wheels?

The purpose of vitrified wheels is to provide a tool for grinding and sharpening materials.

What information must be reported on vitrified wheels?

Information such as type of wheel, size, manufacturer, and date of manufacture must be reported.

When is the deadline to file vitrified wheels in 2024?

The deadline to file vitrified wheels in 2024 is December 31st.

What is the penalty for the late filing of vitrified wheels?

The penalty for late filing of vitrified wheels may include fines or legal consequences.

How can I send vitrified wheels for eSignature?

To distribute your vitrified wheels, simply send it to others and receive the eSigned document back instantly. Post or email a PDF that you've notarized online. Doing so requires never leaving your account.

Where do I find vitrified wheels?

With pdfFiller, an all-in-one online tool for professional document management, it's easy to fill out documents. Over 25 million fillable forms are available on our website, and you can find the vitrified wheels in a matter of seconds. Open it right away and start making it your own with help from advanced editing tools.

Can I create an electronic signature for the vitrified wheels in Chrome?

Yes. By adding the solution to your Chrome browser, you can use pdfFiller to eSign documents and enjoy all of the features of the PDF editor in one place. Use the extension to create a legally-binding eSignature by drawing it, typing it, or uploading a picture of your handwritten signature. Whatever you choose, you will be able to eSign your vitrified wheels in seconds.

Fill out your vitrified wheels online with pdfFiller!

pdfFiller is an end-to-end solution for managing, creating, and editing documents and forms in the cloud. Save time and hassle by preparing your tax forms online.

Not the form you were looking for?

Keywords

Related Forms

If you believe that this page should be taken down, please follow our DMCA take down process

here

.