Get the free Kunkle Safety and Relief Products

Show details

Uncle Safety and Relief Products Models 215V and 337Model 215V is Noncode Vacuum Relief. Model 337 is ASHE Section VIII Air×Gas UV National Board Certified Safety Valve. Both are PED Certified for

We are not affiliated with any brand or entity on this form

Get, Create, Make and Sign

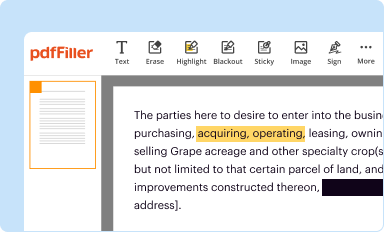

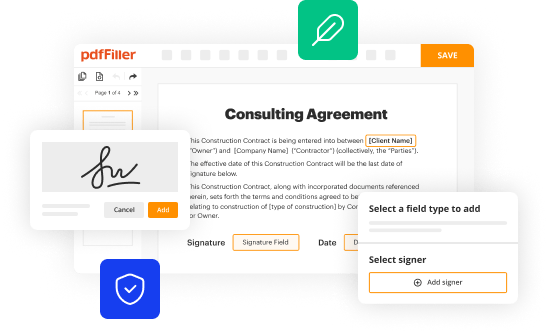

Edit your kunkle safety and relief form online

Type text, complete fillable fields, insert images, highlight or blackout data for discretion, add comments, and more.

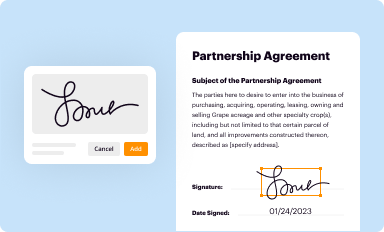

Add your legally-binding signature

Draw or type your signature, upload a signature image, or capture it with your digital camera.

Share your form instantly

Email, fax, or share your kunkle safety and relief form via URL. You can also download, print, or export forms to your preferred cloud storage service.

Editing kunkle safety and relief online

Follow the guidelines below to benefit from the PDF editor's expertise:

1

Register the account. Begin by clicking Start Free Trial and create a profile if you are a new user.

2

Prepare a file. Use the Add New button to start a new project. Then, using your device, upload your file to the system by importing it from internal mail, the cloud, or adding its URL.

3

Edit kunkle safety and relief. Replace text, adding objects, rearranging pages, and more. Then select the Documents tab to combine, divide, lock or unlock the file.

4

Save your file. Select it from your list of records. Then, move your cursor to the right toolbar and choose one of the exporting options. You can save it in multiple formats, download it as a PDF, send it by email, or store it in the cloud, among other things.

With pdfFiller, it's always easy to work with documents. Check it out!

How to fill out kunkle safety and relief

How to fill out Kunkle Safety and Relief:

01

Start by identifying the specific Kunkle Safety and Relief device you are dealing with. Different devices have different specifications, so it's important to know exactly which one you are working on.

02

Familiarize yourself with the instructions provided by Kunkle. These instructions will guide you through the process of filling out the safety and relief device correctly. Pay attention to any specific requirements or recommendations mentioned in the instructions.

03

Ensure that you have all the necessary information and tools at hand. This may include the appropriate documentation, such as the device's model number, specifications, and any relevant certifications or approvals. You may also need tools like a pressure gauge or a wrench to properly fill out the device.

04

Follow the steps outlined in the instructions to complete the filling process. This typically involves opening the device, checking the internal components, and making sure they are clean and in good condition. You may need to adjust some settings or replace certain parts as per the instructions.

05

Before closing the device, double-check that all the required information has been filled out correctly. This may include recording pressure and temperature specifications, setting specific relief pressure levels, or providing other necessary details.

06

Once you are confident that everything is in order, securely close and seal the Kunkle Safety and Relief device. Follow any final steps or checks mentioned in the instructions to ensure proper installation and functioning.

07

It is always recommended to perform a thorough test or inspection after filling out the device to ensure its proper operation. This may involve conducting a pressure test or conducting a functionality check according to the manufacturer's guidelines.

Who needs Kunkle Safety and Relief:

01

Industries: Various industries, such as oil and gas, chemical processing, power generation, and manufacturing, often require the use of Kunkle Safety and Relief devices. These devices help ensure the safe operation of equipment and protect against overpressure situations that could result in equipment damage or personnel injuries.

02

Process Equipment: Equipment that operates under high pressure or temperature conditions, including boilers, pressure vessels, storage tanks, and pipelines, may require the installation of Kunkle Safety and Relief devices. These devices help regulate pressure, relieve excess pressure buildup, and prevent potential hazards.

03

Regulatory Compliance: Many countries have strict regulations in place regarding pressure equipment safety. Compliance with these regulations often requires the installation and proper maintenance of safety and relief devices like Kunkle's. Industries must ensure that their equipment meets the required safety standards and may need to periodically fill out or inspect these devices to comply with regulatory requirements.

04

Safety-conscious Organizations: Any organization that prioritizes safety and risk management should consider using Kunkle Safety and Relief devices. By implementing robust safety measures, these organizations aim to prevent accidents, protect their employees, and avoid costly equipment failures. Kunkle devices play a crucial role in maintaining system safety and preventing catastrophic incidents.

05

Engineers and Maintenance Personnel: Professionals responsible for equipment maintenance, inspection, or system design, including engineers and maintenance personnel, need to have a thorough understanding of the installation and filling process of Kunkle Safety and Relief devices. These professionals ensure that proper measures are in place to protect equipment and personnel, and they play a key role in correctly installing and maintaining these devices.

Fill form : Try Risk Free

For pdfFiller’s FAQs

Below is a list of the most common customer questions. If you can’t find an answer to your question, please don’t hesitate to reach out to us.

What is kunkle safety and relief?

Kunkle safety and relief is a type of pressure relief valve used in industrial applications to protect equipment from overpressure situations.

Who is required to file kunkle safety and relief?

Companies in industries such as manufacturing, oil and gas, and chemical processing are required to file kunkle safety and relief to comply with safety regulations.

How to fill out kunkle safety and relief?

Kunkle safety and relief forms can be filled out online or submitted in hard copy, following the specific guidelines provided by regulatory agencies.

What is the purpose of kunkle safety and relief?

The purpose of kunkle safety and relief is to prevent equipment failures and accidents caused by excessive pressure buildup in industrial systems.

What information must be reported on kunkle safety and relief?

Information such as the type of pressure relief valve used, pressure ratings, installation details, and maintenance records must be reported on kunkle safety and relief forms.

When is the deadline to file kunkle safety and relief in 2024?

The deadline to file kunkle safety and relief in 2024 is typically on or before the end of the calendar year.

What is the penalty for the late filing of kunkle safety and relief?

Penalties for late filing of kunkle safety and relief may include fines or citations from regulatory authorities.

How do I fill out kunkle safety and relief using my mobile device?

On your mobile device, use the pdfFiller mobile app to complete and sign kunkle safety and relief. Visit our website (https://edit-pdf-ios-android.pdffiller.com/) to discover more about our mobile applications, the features you'll have access to, and how to get started.

How do I edit kunkle safety and relief on an iOS device?

No, you can't. With the pdfFiller app for iOS, you can edit, share, and sign kunkle safety and relief right away. At the Apple Store, you can buy and install it in a matter of seconds. The app is free, but you will need to set up an account if you want to buy a subscription or start a free trial.

How do I complete kunkle safety and relief on an iOS device?

Get and install the pdfFiller application for iOS. Next, open the app and log in or create an account to get access to all of the solution’s editing features. To open your kunkle safety and relief, upload it from your device or cloud storage, or enter the document URL. After you complete all of the required fields within the document and eSign it (if that is needed), you can save it or share it with others.

Fill out your kunkle safety and relief online with pdfFiller!

pdfFiller is an end-to-end solution for managing, creating, and editing documents and forms in the cloud. Save time and hassle by preparing your tax forms online.

Not the form you were looking for?

Keywords

Related Forms

If you believe that this page should be taken down, please follow our DMCA take down process

here

.